Manufacturer of Testing Equipment for Flexible Cable Solutions and Applications

The Importance of Testing Equipment for Flexible Cables

In today’s world, flexible cables play a crucial role in a multitude of applications, from consumer electronics to heavy industrial machinery. Their versatility and adaptability allow them to be used in dynamic environments where traditional rigid cables may fail. However, to ensure reliable performance, the testing of flexible cables is paramount. This is where specialized manufacturers of cable testing equipment come into play, providing the tools necessary to verify the integrity and functionality of these essential components.

Understanding Flexible Cables

Flexible cables are designed to withstand bending, twisting, and other movements that occur in everyday use. Unlike standard cables, which are often rigid and prone to damage under stress, flexible cables are constructed with materials and technologies that enable them to endure mechanical strain. They find applications in robotics, mobile devices, automotive systems, and more. However, their flexibility also poses challenges, as they can be more susceptible to wear and tear, which necessitates rigorous testing.

The Role of Testing Equipment

The effectiveness of flexible cables can only be confirmed through comprehensive testing. Cable testing equipment is designed to assess various parameters, including electrical resistance, insulation integrity, and overall durability. This testing is vital for manufacturers seeking to ensure that their products meet regulatory standards and perform reliably over time.

When it comes to testing flexible cables, manufacturers must consider a range of factors. For instance, they need to evaluate the cables' ability to withstand repeated bending, exposure to environmental elements, and potential electrical failures. Advanced testing equipment is capable of simulating real-world conditions, allowing manufacturers to anticipate how their cables will behave in practical applications.

Types of Testing Equipment

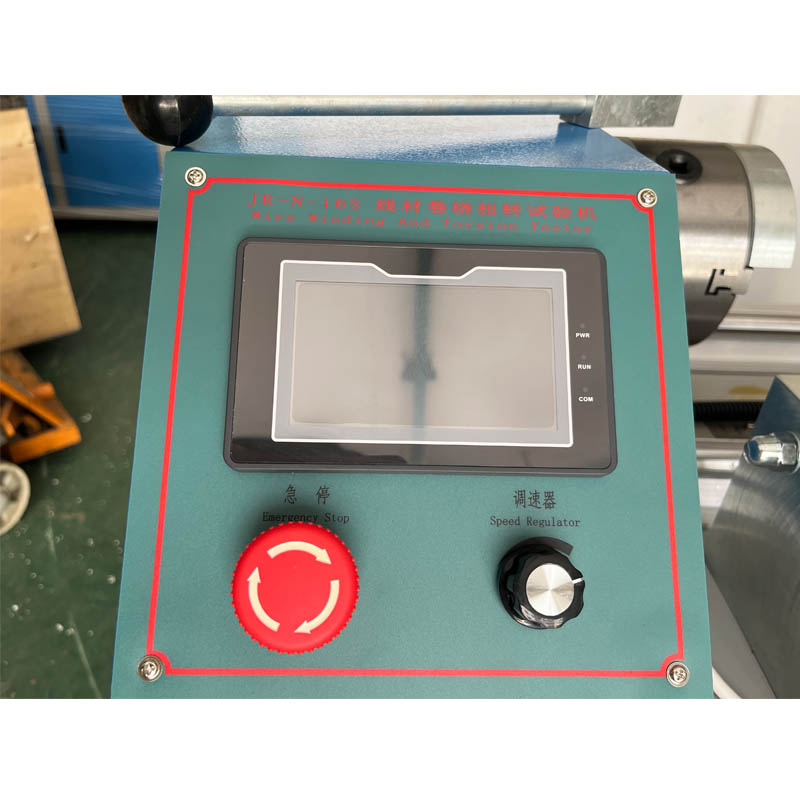

flexible cables testing equipment manufacturer

There are several types of testing equipment used specifically for flexible cables

. Some of the most common include1. Continuity Testers These devices help verify that electrical connections are intact throughout the length of the cable, ensuring there are no breaks or faults that could impede performance.

2. Insulation Resistance Testers Insulation resistance is critical for preventing short circuits and ensuring safety. These testers measure the resistance of the cable's insulation, helping manufacturers detect any weak spots.

3. Bending Test Machines To evaluate how well a flexible cable can handle movement, bending test machines repeatedly flex the cable under controlled conditions. This simulates real-world usage and identifies potential points of failure.

4. Temperature and Humidity Chambers Flexible cables may be exposed to extreme temperatures and humidity levels. Chambers that replicate these conditions can help assess how cables will hold up against environmental stressors.

Conclusion

As flexible cables continue to integrate into diverse applications, the demand for reliable testing equipment becomes increasingly significant. Manufacturers specializing in cable testing equipment play a crucial role in this ecosystem, ensuring that cables meet necessary safety standards and perform as expected. By investing in robust testing methodologies and state-of-the-art equipment, manufacturers can mitigate risks associated with cable failures, ultimately protecting end users and enhancing the reliability of their products.

In a rapidly evolving technological landscape, understanding the importance of flexible cables and their testing requirements is essential for manufacturers. With the right testing equipment, they can ensure that their cables not only meet industry standards but also contribute to the safety and efficiency of the systems they power.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy