high insulation resistance measuring instrument

Understanding High Insulation Resistance Measuring Instruments

In the realm of electrical engineering and maintenance, ensuring the reliability and safety of electrical systems is paramount. One of the critical parameters evaluated during such assessments is insulation resistance. High insulation resistance measuring instruments play a vital role in this regard, serving as essential tools for technicians and engineers responsible for maintaining electrical equipment.

What is Insulation Resistance?

Insulation resistance refers to the ability of an insulating material to resist the flow of electricity. It is critical in preventing leakage currents, which can cause equipment malfunctions, unexpected power losses, and even hazardous situations such as electrical fires. The measurement of insulation resistance is typically expressed in megaohms (MΩ), and a higher value indicates better insulation integrity.

The Importance of High Insulation Resistance

In electrical systems, insulation performs the crucial function of preventing unintentional current flow between conductive components. Over time, however, insulation can degrade due to various factors such as aging, environmental conditions, mechanical stress, and contamination. When insulation resistance decreases to unsafe levels, it can lead to short circuits, equipment failures, or, in severe cases, electric shocks to personnel. Therefore, regular testing of insulation resistance is essential for ensuring operational safety and longevity of electrical equipment.

Overview of High Insulation Resistance Measuring Instruments

High insulation resistance measuring instruments, commonly known as insulation resistance testers or megohmmeters, are designed to assess the insulating capability of electrical systems effectively. These devices apply a high voltage (typically between 250V and 5000V) across the insulation material and measure the resulting current flow. The ratio of the applied voltage to the measured current provides the insulation resistance value.

Types of Insulation Resistance Measuring Instruments

1. Analog Megohmmeters These traditional devices utilize a needle gauge to display resistance readings. While they are straightforward and reliable for basic applications, they lack some advanced features found in modern digital testers.

2. Digital Megohmmeters These instruments have largely replaced their analog counterparts due to their accuracy, ease of use, and advanced features such as data logging, Bluetooth connectivity, and automatic calculations. Digital testers often have backlit displays, making them suitable for use in various lighting conditions.

3. Insulation Resistance Testers with Auto Range These advanced testers automatically select the test voltage and measurement range, simplifying the testing process. Users can perform tests with minimal manual adjustments, enhancing efficiency in fieldwork.

Key Features to Look For

high insulation resistance measuring instrument

When selecting a high insulation resistance measuring instrument, several features should be considered

- Test Voltage Options The ability to select various test voltages allows for testing different insulation types and conditions.

- Data Recording and Analysis Instruments that provide data logging capabilities enable users to track insulation resistance over time, facilitating trend analysis and early detection of insulation degradation.

- Safety Features The device should include features such as automatic discharge of capacitive loads and protection against over-current or incorrect connections.

- Portability Lightweight and durable designs are essential for fieldwork, ensuring ease of transport without compromising functionality.

Best Practices for Insulation Resistance Testing

To achieve accurate and reliable insulation resistance readings, testers should adhere to certain guidelines

1. Preparation Ensure that the equipment is disconnected from all power sources and capacitive components are discharged before testing.

2. Environmental Considerations Conditions such as humidity and temperature can affect readings. It is advisable to perform tests in stable conditions or note the environmental factors influencing the results.

3. Frequency of Testing Regularly scheduled testing is crucial. The frequency can depend on the type of equipment, environmental conditions, and operational demands.

Conclusion

High insulation resistance measuring instruments are indispensable tools in the electrical industry. They play a critical role in diagnosing insulation integrity, ensuring safety, and prolonging the lifespan of electrical systems. By understanding the importance of insulation resistance and utilizing these instruments effectively, technicians can mitigate risks associated with electrical equipment failures, ultimately contributing to a safer and more reliable operational environment.

-

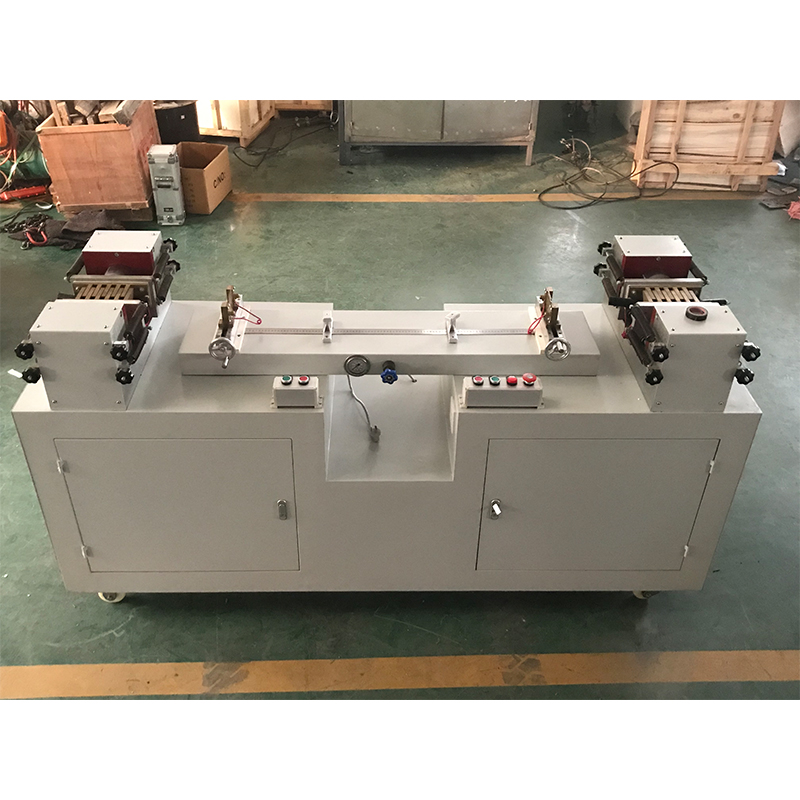

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy