Mechanical Tensile Tester Suppliers for Accurate Material Strength Analysis and Quality Control

The Role of Mechanical Tensile Testers in Modern Industry

In today’s rapidly evolving industrial landscape, the demand for high-quality materials that can withstand considerable stress and strain has never been higher. One of the essential tools for evaluating the mechanical properties of materials is the mechanical tensile tester. These devices are critical for ensuring that materials meet the necessary standards for various applications, from construction to aerospace.

What is a Mechanical Tensile Tester?

A mechanical tensile tester, often referred to as a tensile testing machine, is a device used to measure the tensile strength, yield strength, elongation, and other mechanical properties of materials. The process involves subjecting a specimen to a controlled tension until it fails. This method allows manufacturers and engineers to determine how a material behaves under tensile stress, providing vital data for quality control, research and development, and materials selection.

The testing procedure typically involves gripping the specimen ends in the tester, which then pulls them apart at a constant rate until rupture occurs. The data collected during this process includes the maximum load the material can bear, its elongation before breaking, and the overall modulus of elasticity—valuable metrics needed for understanding material performance.

Importance of Mechanical Tensile Testers

Mechanical tensile testers play a pivotal role across various industries, including automotive, aerospace, construction, and manufacturing. Ensuring that materials can withstand operational demands is crucial for safety and reliability. For example, in the automotive industry, tensile testing is vital for components such as chassis and body parts to ensure they can endure the forces experienced during operation.

Furthermore, tensile testing contributes to the development of new materials. Researchers can use mechanical tensile testers to analyze how certain additives or processes affect a material's properties, leading to innovations in areas such as composite materials and high-strength steel alloys.

Global Export Trends

As industries continue to globalize, the demand for mechanical tensile testers has surged, leading to an increase in exports. Countries with advanced manufacturing sectors, such as Germany, the United States, and Japan, are major exporters of these testing devices. Mechanical tensile testers are often sought after by emerging markets looking to enhance their manufacturing capabilities and improve product quality.

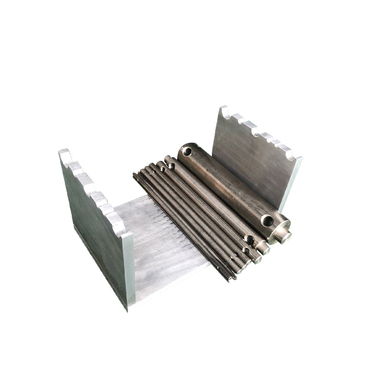

mechanical tensile tester exporter

Exporting mechanical tensile testers not only involves the machinery itself but also includes the necessary calibration services, training, and support that ensure accurate measurements are achieved in different environments. Companies focusing on exporting tensile testers recognize the importance of providing comprehensive packages that meet specific regional standards and user needs.

Key Features of Mechanical Tensile Testers

When considering a mechanical tensile tester, several key features should be taken into account

1. Load Capacity The maximum load the machine can accommodate is critical for testing different materials. 2. Precision and Accuracy High-quality testing machines offer precise measurements, ensuring reliable data for analysis.

3. Ease of Use User-friendly interfaces and software allow operators to conduct tests efficiently and interpret results effectively.

4. Safety Features Given the high forces involved, safety mechanisms are essential to protect operators and equipment.

5. Adaptability Flexibility to test various materials—from metals to plastics—makes a tensile tester more valuable.

Conclusion

Mechanical tensile testers serve as a cornerstone in the evaluation and assurance of material properties across a multitude of industries. Their roles are magnified by the global demand for rigorous quality standards and innovative material solutions. As the market for these testing devices continues to grow, exporters will play an essential role in providing the technology needed to meet the evolving challenges of modern manufacturing. By investing in high-quality machinery and support, companies can ensure that they are equipped to enhance their material testing capabilities and maintain a competitive edge in the global market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy