Precision Optical Measurement Machines | Advanced Measurement Solutions

The Evolution and Importance of Optical Measurement Machines in Manufacturing

In the realm of modern manufacturing, precision is paramount. As businesses strive to enhance quality and efficiency, the role of optical measurement machines has become increasingly significant. These advanced devices utilize sophisticated optical technologies to measure dimensions, surface features, and geometrical properties of various components with remarkable accuracy. With the rapid advancements in technology, optical measurement machines have evolved to meet the diverse needs of different industries, including automotive, aerospace, electronics, and more.

Optical measurement machines operate by projecting light onto a surface and capturing the reflected light through a series of high-resolution cameras or sensors. This method allows for non-contact measurements, which is a critical advantage when dealing with delicate or intricate components. The ability to measure without physical contact ensures that the pieces maintain their integrity and that the measurements are highly reliable.

One of the most prominent types of optical measurement machines is the Coordinate Measuring Machine (CMM). CMMs equipped with optical sensors can provide accurate three-dimensional measurements of an object’s shape and size. Unlike traditional mechanical CMMs, optical CMMs can offer faster measurements and have the additional ability to analyze surface finishes, making them indispensable in quality control processes.

Another notable innovation in the field of optical measurement is the introduction of 3D laser scanners. These machines have revolutionized the way manufacturers assess parts and assemblies. Equipped with laser technology, they can quickly capture the surface geometry of complex shapes, resulting in a point cloud that can be analyzed to ensure adherence to design specifications. This capability not only improves the accuracy of reverse engineering but also plays a vital role in inspection and maintenance procedures.

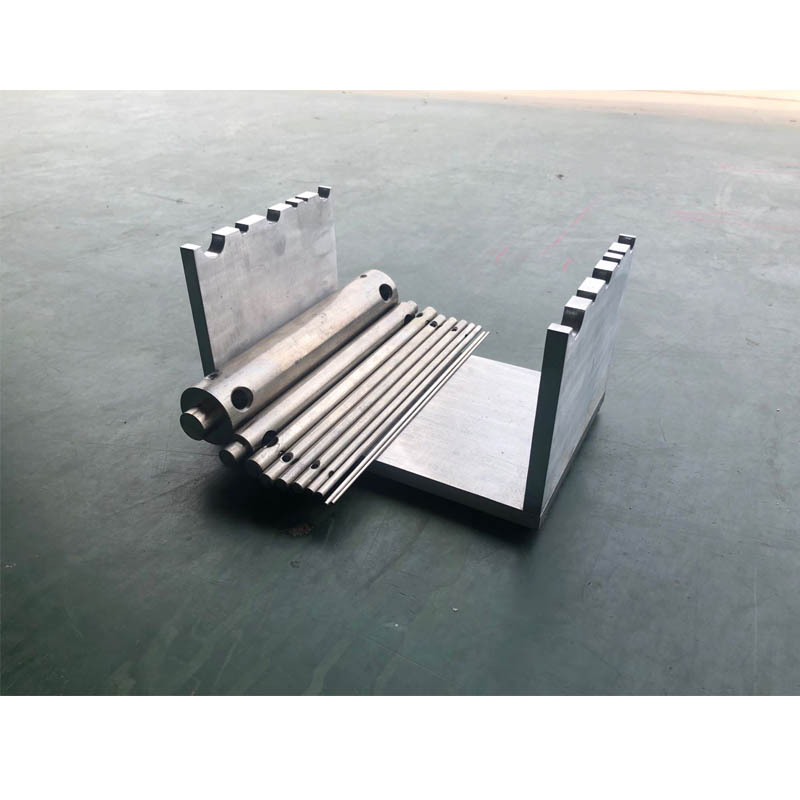

optical measurement machine factory

Factories equipped with optical measurement machines benefit from significant time savings and increased throughput. Automated measurement processes reduce the risk of human error and allow for real-time feedback in the production line. As a result, manufacturers can promptly address quality issues, thereby reducing waste and enhancing productivity.

Furthermore, the integration of optical measurement machines with digital technologies, such as artificial intelligence (AI) and machine learning, is paving the way for smart manufacturing. These technologies enable predictive analytics, which can forecast potential defects before they occur, thereby further improving quality assurance processes. The synergy between optical measurement machines and advanced technologies enhances operational efficiency and drives the digital transformation of manufacturing facilities.

The importance of optical measurement machines extends beyond individual factories; they are crucial for maintaining competitiveness in the global market. Companies that invest in high-precision measurement technologies often find themselves at the forefront of innovation. They can produce higher quality products, respond more quickly to customer demands, and adapt to changing market conditions with agility.

In conclusion, the development and implementation of optical measurement machines in manufacturing are transformative. Their ability to deliver precise, reliable measurements efficiently is essential for quality control and enhancing production processes. As technology continues to advance, the role of these machines will only become more pivotal, driving innovation and ensuring that manufacturers can meet the challenges of an ever-evolving marketplace. Embracing optical measurement technology is not only a step towards improved efficiency but also a commitment to excellence in manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy