Tensile Strength Tester - Precision Testing Solutions

Understanding Tensile Strength Testers A Key to Material Durability

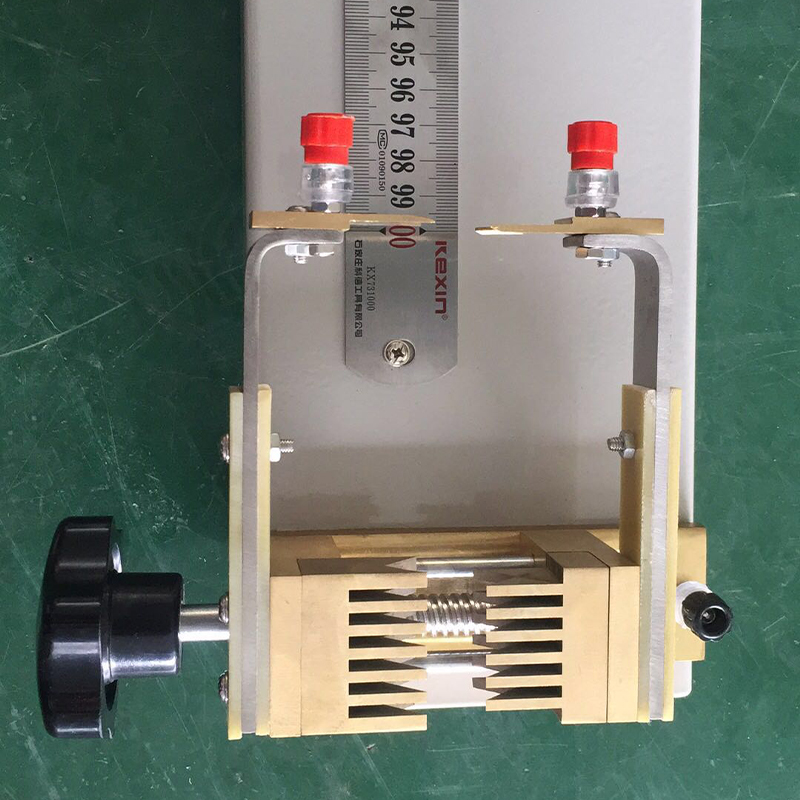

Tensile strength testers are essential instruments used in material science to evaluate the mechanical properties of a wide range of materials, including metals, plastics, composites, and textiles. These testers measure the amount of pulling force a material can withstand before failing, providing critical data that engineers and manufacturers rely on to ensure product performance, safety, and durability.

The basic principle behind a tensile strength tester is straightforward. The material sample, often shaped into a standardized form, is placed in the machine, which grips both ends of the sample. As the machine applies a tensile load, it stretches the material until it reaches its breaking point. This process measures two critical parameters the maximum load the material can endure (ultimate tensile strength) and the extent of its deformation (elongation) before rupture.

One of the most significant aspects of tensile testing is its ability to reveal important characteristics of materials. For instance, materials with high tensile strength can be used in applications that require durability under stress, such as construction beams or aerospace components. Conversely, materials that exhibit lower tensile strength might be suited for applications where flexibility and ease of deformation are necessary, such as in the production of rubber products or packaging materials.

tensile strength tester

The results from tensile strength tests play a pivotal role in the design and quality control processes in manufacturing. Engineers can use the data to predict how materials will behave under various conditions, allowing for more informed decisions when it comes to material selection and design specifications. Furthermore, regular testing ensures that production processes consistently yield materials that meet safety standards and performance requirements.

In addition to providing crucial data, tensile strength testers can also help in research and development. By experimenting with different compositions and treatments, researchers can identify new materials or enhance existing ones, pushing the boundaries of what materials can achieve. This continuous innovation is vital in industries such as automotive, aerospace, and construction, where performance and reliability are paramount.

Moreover, advancements in technology have led to the development of more sophisticated tensile strength testers. Modern machines often come with digital interfaces, allowing for precise measurements and easy data analysis. These advancements improve the efficiency of testing processes and enhance the accuracy of results, empowering engineers and manufacturers to make better-informed decisions.

In conclusion, tensile strength testers are a fundamental tool in material science and engineering. They help ensure the reliability and safety of materials and products in various industries. As technology advances, the importance of these testers will likely continue to grow, paving the way for innovations and improvements in material performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy