Top Manufacturers of Tensile Testing Equipment for Accurate Material Analysis

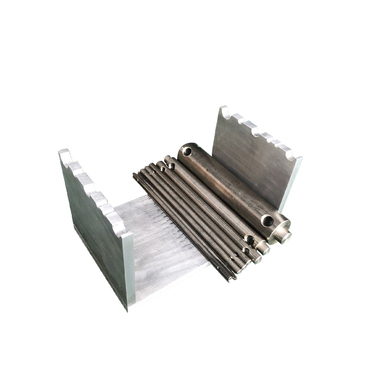

When it comes to material testing, a tensile tester is an essential piece of equipment for manufacturers across various industries. These devices are designed to evaluate the tensile strength, elongation, and other mechanical properties of materials, providing valuable insights during the product development and quality control processes. As such, the role of tensile tester manufacturers is paramount in ensuring that reliable, accurate, and efficient testing equipment is available to meet the diverse needs of different sectors.

Tensile testers, often referred to as universal testing machines (UTMs), come equipped with various features that enhance their usability. For example, many modern tensile testers are integrated with advanced software that allows users to precisely analyze the results, generate comprehensive reports, and even perform real-time data monitoring. This technological advancement helps manufacturers achieve a higher level of accuracy in testing, which is crucial for industries that demand stringent quality standards, such as aerospace, automotive, and construction.

The market for tensile tester manufacturers is quite competitive, with numerous companies offering a range of products catering to different materials and testing requirements. Some manufacturers specialize in entry-level models suitable for educational institutions and smaller businesses, while others focus on high-end machines capable of handling complex materials like composites and biomaterials. Regardless of the target audience, quality is a consistent theme among reputable manufacturers, who invest in research and development to improve their machines continuously.

tensile tester manufacturers

Furthermore, the importance of having a reliable tensile tester cannot be overstated. The data collected from tensile testing can inform decisions about material selection, product design, and safety assessments. This makes the role of tensile tester manufacturers critical in supporting industries that prioritize innovation and excellence. Many manufacturers also offer calibration and maintenance services, ensuring that their machines operate at optimum levels and continue to provide accurate results over time.

Another notable aspect is the trend toward sustainability. As industries increasingly shift their focus toward sustainable practices, tensile tester manufacturers are incorporating eco-friendly materials and energy-efficient technologies into their designs. This positive shift not only benefits the environment but also meets the growing demand from consumers for products made with sustainability in mind.

In conclusion, tensile tester manufacturers play a vital role in the landscape of material testing. Their commitment to delivering high-quality, technologically advanced testing machines aids various industries in maintaining standards of excellence and safety. As the market evolves and new materials emerge, the collaboration between manufacturers and end-users will undoubtedly foster further innovation and improvement in tensile testing methods, paving the way for future advancements in material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy