Choosing the Right Manufacturer for Your Tensile Testing Machine Needs

Understanding Tensile Testing Machines A Comprehensive Overview

In the realm of materials science and engineering, tensile testing machines play a pivotal role in assessing the strength and ductility of materials. These machines are designed to measure how materials respond to tensile forces, offering crucial data that informs manufacturers, engineers, and researchers about the quality and reliability of materials used in various applications.

What is a Tensile Testing Machine?

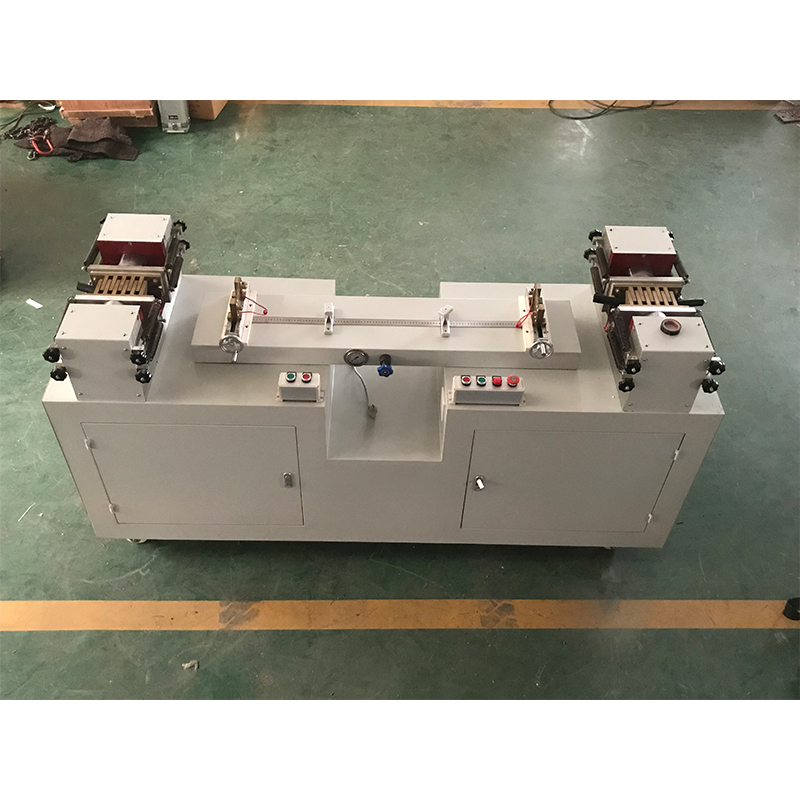

A tensile testing machine, also known as a tensile tester or tensile strength machine, is an apparatus designed to determine the behavior of materials when subjected to tension. It measures the force required to stretch or elongate a sample until failure, providing data about its tensile strength, yield strength, and elongation percentage. Typically, these machines are used for testing metals, plastics, textiles, and composites, among other materials.

Key Components of a Tensile Testing Machine

A typical tensile testing machine consists of several key components

1. Load Frame The primary structure that houses the testing setup. It provides the stability needed to accurately measure the forces applied to the specimen.

2. Load Cell An essential device that measures the amount of force exerted on the material being tested. It converts mechanical force into an electrical signal that can be quantified.

3. Grips These are devices used to hold the material specimen in place during testing. The type of grip can vary depending on the material being tested to ensure there is no slipping or slippage.

4. Crosshead The moving component of the machine that applies the tensile force to the specimen. The crosshead travels vertically, pulling the sample apart until it fractures.

5. Control System Modern tensile testing machines are equipped with computer systems that control the speed of the crosshead, record data, and provide real-time analysis of the tensile test results.

6. Software Advanced software systems are integral to tensile testing machines, facilitating data collection and analysis. They enable users to generate comprehensive reports and visual representations of the test results.

The Importance of Tensile Testing

Tensile testing is crucial for various reasons

tensile testing machine manufacturer

- Materials Selection Engineers rely on tensile test data to select appropriate materials for specific applications, ensuring that they meet required strength and durability standards.

- Quality Control Manufacturers use tensile testing as a part of their quality control processes to ensure that their products consistently meet predefined specifications and standards.

- Research and Development Tensile testing provides valuable insights during the development of new materials or products, helping researchers understand how different compositions or treatments affect material performance.

- Regulatory Compliance Many industries, such as aerospace and automotive, have stringent regulations regarding material properties. Tensile testing helps companies demonstrate compliance with these standards.

Choosing a Tensile Testing Machine Manufacturer

Selecting the right manufacturer for tensile testing machines is crucial for ensuring accurate and reliable testing. Here are factors to consider

1. Reputation Look for manufacturers with a strong track record in the industry. Reviews, testimonials, and case studies can provide insights into their reliability and the quality of their machines.

2. Technical Support A manufacturer should offer excellent customer support, including assistance with installation, maintenance, and troubleshooting.

3. Customization Options Different industries may require specific features or capabilities. Choose a manufacturer that can tailor their machines to meet your unique requirements.

4. Technology Look for manufacturers that utilize cutting-edge technology in their machines, providing accurate readings and a user-friendly experience.

5. Warranty and Service A solid warranty and after-sales service are essential to ensure longevity and reliability in your investment.

Conclusion

In summary, tensile testing machines are invaluable tools in evaluating material properties, contributing to safer, more efficient, and higher-quality products across various industries. By understanding the significance of these machines and selecting a reputable manufacturer, organizations can leverage the benefits of tensile testing to enhance their material selection, quality assurance, and research and development efforts. Whether for industrial applications or academic research, the importance of tensile testing remains a cornerstone of materials engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy