XP-19T Wire & Cable Chipping Machine: High-Efficiency Copper Granulator

Navigating the Evolving Landscape of Wire and Cable Recycling

The global demand for efficient and environmentally responsible material recovery has intensified, particularly within the recycling of non-ferrous metals. Waste wire and cable, a significant component of electronic and industrial scrap, represents a valuable resource containing substantial quantities of copper, aluminum, and plastics. Industry trends indicate a consistent push towards higher purity separation, reduced energy consumption, and compliance with stringent environmental regulations. Advanced processing solutions, such as the XP-19T Wire and Cable Chipping Machine, are crucial in addressing these evolving requirements, enabling businesses to achieve superior material recovery rates and enhance operational profitability. The focus is no longer just on recovery, but on optimizing the entire lifecycle, from collection to high-purity material reintroduction into manufacturing. This shift underscores the need for robust, reliable, and highly efficient chipping and separation technologies that minimize waste and maximize resource value.

Moreover, escalating commodity prices and the circular economy paradigm are driving innovation in waste processing machinery. Companies are actively seeking solutions that not only provide high throughput but also ensure minimal operator intervention and maximum safety. The challenge lies in efficiently separating materials with different specific gravities and compositions, especially in complex mixed cables. The industry is moving away from traditional burning methods due to environmental concerns, embracing mechanical separation as the preferred, sustainable alternative. This technological evolution impacts every segment, from small-scale recyclers to large industrial processing plants, necessitating machinery that delivers consistent performance and adheres to global recycling standards.

Unpacking the XP-19T Wire and Cable Chipping Machine: Process and Precision

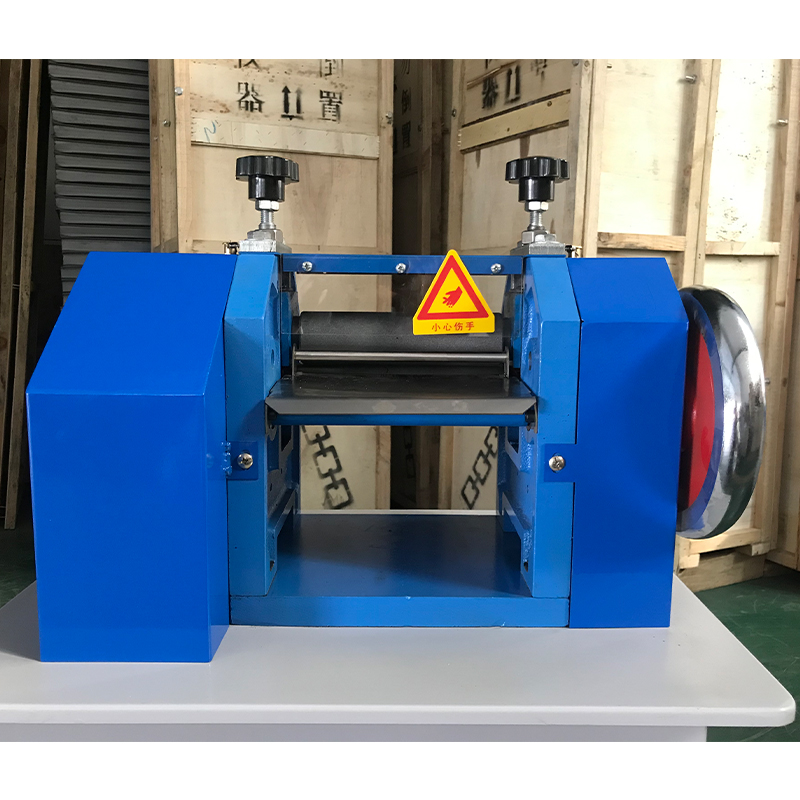

The core function of the XP-19T Wire and Cable Chipping Machine lies in its multi-stage mechanical separation process, designed for optimal recovery of copper and aluminum from various types of scrap cables. The journey begins with shredding: bulk cables are fed into a primary shredder, reducing them into manageable lengths. This pre-processing step is critical for consistent feeding and preventing blockages in subsequent stages. Following shredding, the material undergoes granulation in a specialized granulator, where rotating blades cut the cable fragments into fine granules, effectively detaching the metal conductors from their insulation. The granulator's design, often featuring high-grade alloy steel blades, ensures durability and efficient size reduction, directly impacting the purity of the final output.

Post-granulation, the mixed material (metal granules and plastic insulation) is transferred to a sophisticated air separation system. This crucial stage utilizes differences in specific gravity and aerodynamics. A powerful fan generates an upward air current, lifting lighter plastic particles while heavier metal particles fall through, separating the two components. For enhanced purity, some systems integrate electrostatic separation or vibrating screens to further refine the output, achieving metal purity levels exceeding 99.5%. The manufacturing process for the XP-19T Wire and Cable Chipping Machine itself adheres to rigorous standards, utilizing robust materials such as high-carbon alloy steel for cutting components and durable structural steel for the machine frame, ensuring longevity and resistance to wear. CNC machining is employed for critical parts to guarantee precision and interchangeability, while all components undergo strict quality control, including adherence to ISO 9001 and ANSI standards for mechanical integrity and performance. This meticulous approach results in a machine with an extended operational lifespan, typically exceeding 10 years with proper maintenance, significantly contributing to sustainable recycling efforts across various industries.

Technical Specifications and Performance Metrics

Understanding the technical parameters of the XP-19T Wire and Cable Chipping Machine is essential for assessing its suitability for specific recycling operations. This machine is engineered for high efficiency and reliability, making it a preferred choice for medium to large-scale waste cable processing. Its design optimizes energy consumption while maximizing output purity, aligning with modern industrial demands for both productivity and environmental responsibility. The integrated dust collection system is a notable feature, ensuring a clean working environment and compliance with air quality regulations. Below is a detailed table outlining the key specifications for the XP-19T model, providing a clear overview of its capabilities.

| Parameter | Value | Unit/Description |

|---|---|---|

| Model | XP-19T | Wire and Cable Chipping Machine |

| Processing Capacity | 200-300 | kg/hour (depending on cable type) |

| Copper Purity | >99.5% | Achieved metal purity |

| Power Consumption | 22-30 | kW (total installed power) |

| Applicable Wire Diameter | 0.5-20 | mm |

| Blade Material | HSS/SKD-11 | High Speed Steel / High Carbon High Chromium Die Steel |

| Separation Method | Airflow + Vibration | Gravity and specific density based |

| Dust Collection System | Integrated Cyclonic Filter | Environmental compliance |

| Dimensions (L x W x H) | Approx. 3000 x 1800 x 2500 | mm |

| Weight | Approx. 2500 | kg |

These specifications highlight the machine's capability to handle a wide range of wire and cable types, from thin communication lines to thicker industrial cables. The high copper purity output makes the recovered metal highly valuable for direct re-smelting or resale, significantly increasing the return on investment for recycling operations. The machine's robust construction and optimized power consumption reflect its commitment to both operational efficiency and long-term sustainability, an essential consideration for any B2B stakeholder in the recycling sector.

Versatile Application Scenarios and Core Advantages

The adaptability of the XP-19T Wire and Cable Chipping Machine extends its utility across diverse industrial and commercial recycling environments. It is ideally suited for scrap yards, electronic waste recycling facilities, industrial manufacturing plants generating cable off-cuts, and specialized metal recovery centers. Its ability to process various cable types—including household electrical wires, automotive harnesses, telecommunication cables, and industrial power cables—makes it an indispensable asset in comprehensive recycling operations. Beyond its direct application in wire recycling, the high purity of separated materials supports secondary industries such as copper smelting, plastic compounding, and even the manufacturing of new cables.

The technical advantages of the XP-19T Wire and Cable Chipping Machine are multifaceted. Firstly, its high separation efficiency, achieving over 99.5% copper purity, ensures maximum material recovery and increased profitability. This superior separation performance minimizes the amount of valuable metal lost in the plastic fraction. Secondly, the system's low energy consumption per ton of processed material translates to significant operational cost savings, making it an economically attractive investment. Thirdly, the integrated dust collection system and fully enclosed design contribute to a clean, safe, and environmentally compliant operation, mitigating airborne particulate matter and ensuring worker safety. Finally, the machine's robust construction and use of wear-resistant components (e.g., SKD-11 blades) ensure remarkable durability and a long service life, minimizing downtime and maintenance costs. These combined benefits reinforce its position as a leading solution for modern wire and cable recycling needs.

Comparative Analysis: XP-19T vs. Conventional Systems

In a competitive market, understanding how the XP-19T Wire and Cable Chipping Machine stands against other conventional or older-generation recycling systems is vital. Traditional methods, such as manual stripping or simple shredding, often yield lower purity, higher labor costs, and significant environmental impact. The XP-19T, as a sophisticated mechanical separation solution, offers distinct advantages across key performance indicators. Its advanced design incorporates multi-stage processing that ensures comprehensive material liberation and separation, a capability often lacking in less integrated systems. This holistic approach sets it apart, demonstrating superior value proposition for businesses focused on sustainability and efficiency.

| Feature | XP-19T Chipping Machine | Conventional Recycling System |

|---|---|---|

| Metal Purity (Copper) | >99.5% | 70-90% (often requires further processing) |

| Environmental Impact | Low (Integrated Dust Collection, No Burning) | High (Dust, Smoke, Pollution from Burning) |

| Automation Level | High (Automated feeding, separation) | Low to Medium (High Labor Dependence) |

| Operational Cost | Lower (Energy Efficient, Less Labor) | Higher (Labor Intensive, Energy Inefficient) |

| Maintenance Frequency | Low (Durable Components) | Moderate to High (Component Wear) |

| Versatility in Cable Types | High (Mixed Wires, Automotive, Industrial) | Limited (Often struggles with complex cables) |

This comparison highlights the significant leap in technology offered by the XP-19T Wire and Cable Chipping Machine. Its emphasis on high purity, environmental compliance, and reduced operational costs positions it as a superior investment for businesses aiming for sustainable and profitable recycling operations. The lower maintenance requirements and higher degree of automation further contribute to an optimized total cost of ownership, providing a clear competitive edge in the recycling industry.

Custom Solutions and Proven Application Cases

Recognizing that each recycling operation has unique requirements, manufacturers of the XP-19T Wire and Cable Chipping Machine often offer tailored solutions. Customization options can include modifications to processing capacity, integration with existing material handling systems, adjustments for specific cable types (e.g., armored cables, very fine wires), and advanced sensor-based sorting for even higher purity. These bespoke configurations ensure that the machine seamlessly integrates into diverse operational workflows, optimizing overall plant efficiency. Our team collaborates closely with clients, conducting thorough assessments of their specific waste streams and throughput demands to design a system that precisely meets their needs, thereby maximizing ROI and operational effectiveness.

Several real-world application cases underscore the effectiveness of the XP-19T Wire and Cable Chipping Machine. For instance, a major electronic waste recycling facility in Europe reported a 15% increase in copper recovery rates and a 20% reduction in processing time after integrating the XP-19T into their existing line, specifically for mixed household cables and automotive harnesses. Another prominent case involves a large-scale scrap metal dealer in North America who utilized a customized XP-19T setup to process large volumes of industrial power cables, achieving consistent 99.7% copper purity, which significantly boosted their revenue from commodity sales. These examples demonstrate the machine's robust performance, adaptability, and direct contribution to enhancing profitability and environmental sustainability across different scales and sectors within the recycling industry.

Frequently Asked Questions (FAQ)

Q1: What types of cables can the XP-19T Wire and Cable Chipping Machine process?

A1: The XP-19T Wire and Cable Chipping Machine is designed to process a wide variety of scrap cables, including household wires, communication cables, automotive cables, industrial power cables, and mixed wires with diameters ranging from 0.5mm to 20mm. It efficiently separates both copper and aluminum from their plastic or rubber insulation.

Q2: What is the typical copper recovery purity achieved by this machine?

A2: The XP-19T Wire and Cable Chipping Machine is engineered to achieve a high copper recovery purity, typically exceeding 99.5%. This high purity ensures the recovered copper is suitable for direct re-smelting or high-value resale, maximizing your return on investment.

Q3: What are the power requirements and energy consumption?

A3: The total installed power for the XP-19T Wire and Cable Chipping Machine ranges from 22kW to 30kW, depending on specific configurations and ancillary equipment. It is designed for energy efficiency, minimizing operational costs per ton of processed material.

Q4: What are the maintenance requirements for the XP-19T?

A4: Thanks to its robust construction and use of wear-resistant materials like HSS/SKD-11 blades, the XP-19T Wire and Cable Chipping Machine requires minimal maintenance. Routine checks include blade sharpening/replacement, lubrication, and cleaning of filters. A comprehensive maintenance schedule is provided with each machine.

Commitment to Quality: Delivery, Warranty, and Support

Our commitment to customer satisfaction extends beyond the sale of the XP-19T Wire and Cable Chipping Machine. We adhere to rigorous quality control standards, with each unit undergoing comprehensive testing before shipment to ensure optimal performance upon installation. The typical delivery period ranges from 4 to 8 weeks, depending on customization requirements and current production schedules. This timeline includes manufacturing, assembly, and thorough quality assurance checks. We maintain transparent communication throughout the entire process, providing regular updates to our clients.

All XP-19T Wire and Cable Chipping Machine units come with a standard 12-month warranty covering manufacturing defects and major component failures, commencing from the date of installation or commissioning. Our dedicated customer support team is available to provide technical assistance, troubleshooting, and spare parts procurement. We offer remote diagnostics, on-site support by experienced technicians (if required), and training programs to ensure your operational staff are fully proficient in operating and maintaining the equipment. Our long-term service commitment ensures continued peak performance and maximum uptime for your investment in advanced recycling technology.

References

- European Environment Agency. (2023). "Recycling rates of municipal waste in Europe."

- International Copper Study Group. (2022). "The Role of Copper in the Circular Economy."

- American Society for Testing and Materials (ASTM International). (2021). "Standard Test Method for Mechanical Separation of Recyclable Materials."

- Waste Management & Recycling Journal. (2023). "Innovations in Non-Ferrous Metal Recovery Technologies."

- United Nations Environment Programme (UNEP). (2022). "E-waste Recycling: Environmental and Economic Implications."

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy