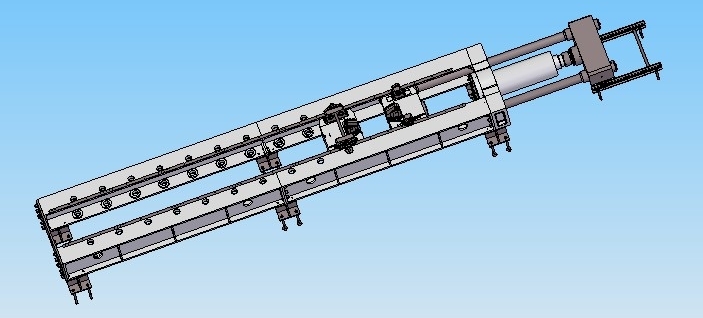

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Imashini Yipimisha

Ibisobanuro ku bicuruzwa

TXWL-600 electro-hydraulic servo horizontal tensile imashini igerageza ifata imiterere ya horizontal, inkoni imwe ikora kabiri ya piston silinderi ikoresha imbaraga zo kugerageza, kandi sisitemu yo kugenzura mudasobwa ikamenya kugenzura byikora gahunda yikizamini igenzura valve ya servo nibindi bice, ikizamini amakuru yakusanyijwe neza na sensor yumutwaro kandi yoherezwa kuri mudasobwa, sisitemu ihita isesengura, ikora kandi ikabika ibisubizo byikizamini, kandi printer irashobora gucapa neza raporo yikizamini gisabwa. Iyi mashini ikoreshwa cyane cyane mugupima umurongo wumugozi wicyuma, ni umusaruro ugezweho wubushakashatsi bwa siyansi ninyigisho hamwe nizindi nganda kugirango zuzuze ibisabwa nibikoresho byiza byo gupima.

Imashini Ibisobanuro

1.Uburyo bwa sisitemu

Igice cyimashini nyamukuru kigizwe ahanini nimashini nyamukuru, intebe ya peteroli, icyuma cya peteroli, urumuri rugenda, intebe yimbere ninyuma hamwe na sensor yimitwaro. Irashobora gukora ikizamini cya tensile hamwe nuburemere ntarengwa bwa 600kN kurugero.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Agace k'ibizamini gafite igifuniko gikingira, gishobora kurinda neza umutekano w'abakozi bakora ibizamini.

2.Amavuta ya sisitemu

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Icyiciro cy'amashanyarazi

Igenzura ry'amashanyarazi ritunganijwe ahakorerwa ibizamini, kandi hariho akanama gashinzwe gukora kuburyo bwihariye kugirango ibikorwa byose bisobanuke neza. Ibice byamashanyarazi nibirango mpuzamahanga bizwi, hamwe nibikorwa bihamye kandi byizewe.

Sisitemu ya software:

. kurwego ntarengwa, no kumenya amakuru atandukanye yerekana, gushushanya umurongo, gutunganya amakuru, kubika no gucapa imirimo isabwa kugirango ikizamini.

. .

.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

. byihuse.

(6) Amakuru arashobora gusohoka kuri printer kugirango yandike raporo yikizamini.

.

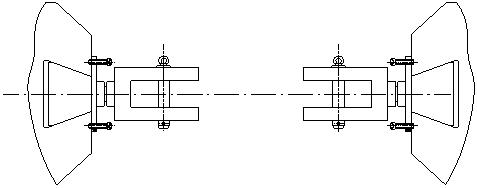

4.Gupima ibikoresho

Bifite ibikoresho byo gupima umugozi wibikoresho (reba hano hepfo) nibindi bikoresho bikozwe ukurikije igipimo cyatanzwe numukoresha cyangwa ibisabwa byintangarugero byicyitegererezo.

5.Ibikoresho byo Kurinda Umutekano

.

(2) Kurinda inkoni iyo piston yimukiye kumwanya ntarengwa.

(3) Hamwe n'ubushyuhe bwa peteroli, urwego rwamazi hamwe nuburinzi bwamavuta hamwe nibikoresho byerekana.

(4) Umwanya wikizamini ufite igifuniko cyo gukingira kugirango wirinde icyitegererezo kumeneka no kugwa.

(5) Mugihe habaye ikibazo cyihutirwa, kanda buto yo guhagarika byihutirwa kurwego rwabashinzwe kugenzura

Ikigereranyo cya tekiniki

1.Imbaraga ntarengwa zo kwipimisha: 600kN

2.Ibipimo byo gupima imbaraga: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Umwanya wikizamini (usibye piston ya piston): 20mm ~ 12000mm

5.Imitsi ya piston: 1000mm

6.Umuvuduko ntarengwa wakazi wa piston: 100 mm / min

7.Ivugurura ryagutse ryuzuye: 0.01mm

8.Igipimo cyimashini nyamukuru (mm): 16000 (L) x 1300 (W) x 1000 (H) (ukuyemo igifuniko cyo gukingira)