LED Ultraviolet Irradiation Polyolefin Crosslinking Meafaigaluega

Fa'amatalaga o oloa

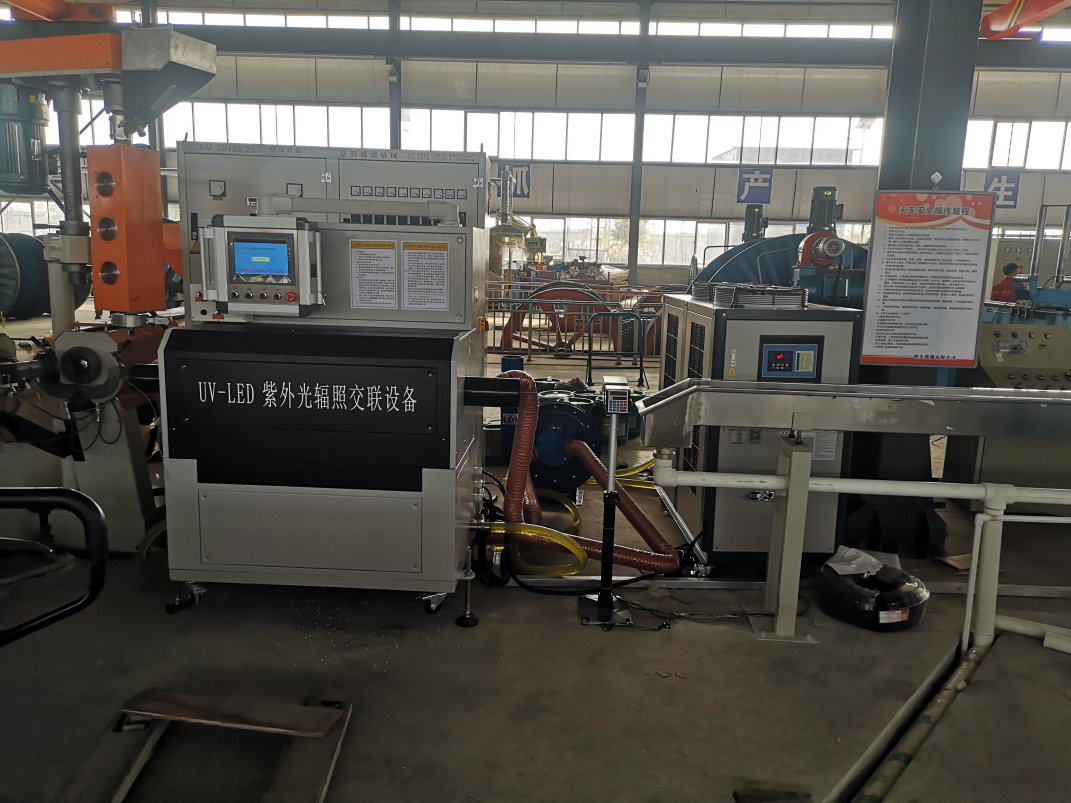

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

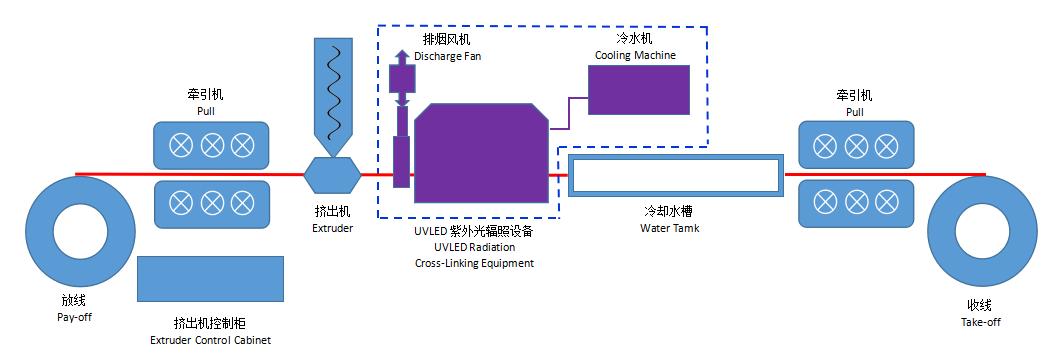

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Uiga

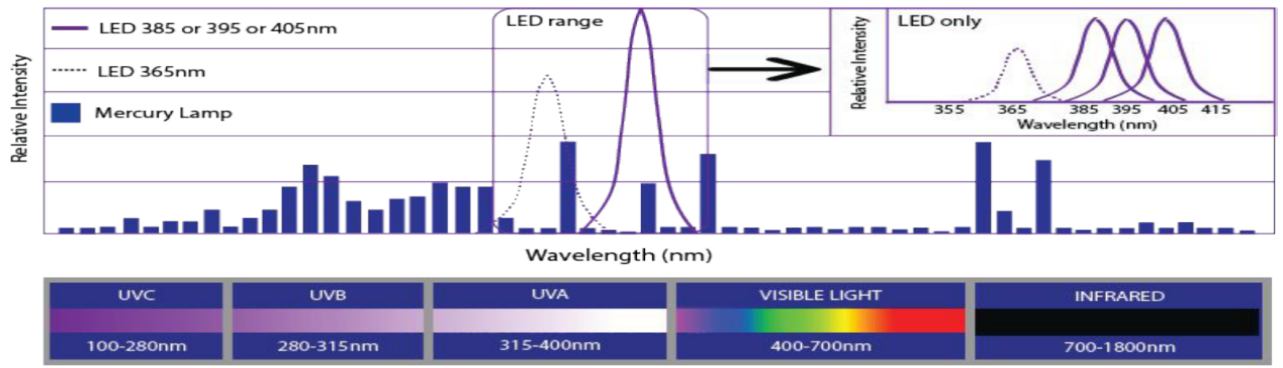

Ultraviolet LED masini o le puna sili ona maualuga o le ultraviolet radiation i le lalolagi, faʻatasi ai ma le maualuga o le malosi (e tusa ma le 30%), e sili atu le maualuga o le maualuga o le galu o le galu (afa-power wavelength bandwidth 5nm), ola maualuga maualuga (30,000 itula), infrared Low heat. fa'atuputeleina, leai se fa'atupuina o le osone, e sili atu ona talafeagai mo le fa'amalo fa'aola o polyolefin fa'afeso'ota'i ma isi mea.

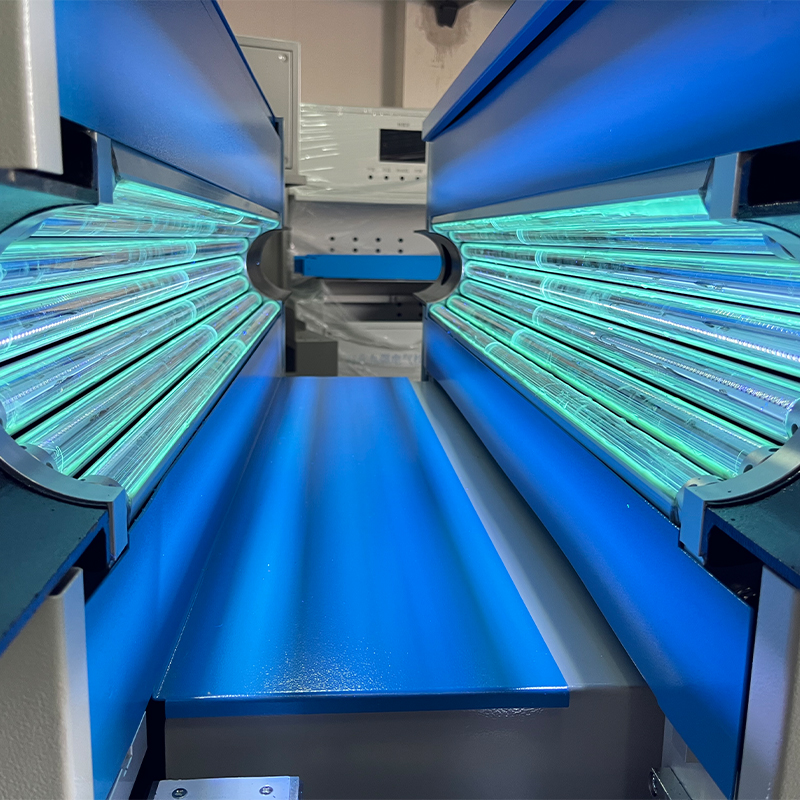

O le fa'apogai o le UV LED e fa'aogaina ai se fausaga tioata pateni e fa'amalamalama atili ai le fa'amalamaina o le uaea ma tutusa. O le mamanu o le substrate o loʻo faʻatinoina e ala i le tuʻufaʻatasia o le Fluent software simulation fluid ma le suʻega o le vevela o le LED, ma o le laupapa vaʻavaʻa LED ua mamanuina e ala i le tuʻufaʻatasia o le alumini nitride ceramic ma le kopa faʻavae ma sili atu le faʻaogaina o le vevela, ma e sili atu le lelei o le vevela. faiga.

O le fa'apogai o le UV LED e fa'aaogaina ai le fa'asoa fa'asoa feso'ota'iga puna eletise e ave ai le UV LED. O lo'o fa'apipi'iina le tu'uina atu o le mana fa'ata'ita'i i totonu o se fa'agasologa o le vacuum potting e fa'amautinoa ai le fa'amaoni o le sapalai eletise. I le taimi lava e tasi, o le foliga o le faʻaogaina o le eletise e faʻaaogaina ai se vaʻaiga vaapiapi ma umi, ma o le faʻamalama moli faʻamalama umi e faʻaaogaina se faiga faʻapipiʻi tua i tua mo le taʻavale LED e faʻaitiitia ai le umi o le uaea. Ia iloa le fa'apogai o le moli o lo'o ola, pa'u, ma fa'apouliuli.

O le UV LED irradiation polyolefin cross-linking meafaigaluega e faʻaaogaina ai se fausaga faʻalava o le lua, ma faʻapipiʻiina i se faʻamalama malamalama ultraviolet e fausia ai se alavai mo le faʻafefeina o le itulagi tutotonu, ma o le mana o le masini e mafai ona faʻatulagaina i le va o le 10. i le 100%.

Fa'atusatusa i tu'aiga moli mercury tu'aiga irradiation feso'ota'iga mea faigaluega (traditional transformer-driven UVI/UVII ma eletise eletise UVE-I), fa'aeletonika accelerator cross-linking, ma silane cross-linking, o lo'o i ai tulaga lelei nei:

1 Fa'atauga Malosiaga maualalo

UV LED irradiation polyolefin cross-linking meafaigaluega faʻapipiʻiina le mana e tutusa ma le 1/4 o le uluai masini faʻavevela ultraviolet, 1/30 o le eletise eletise, vai poʻo vai vai e manaʻomia le faʻamafanafanaina umi, ma le faʻaaogaina o le malosi o le vai faʻavevela e matuaʻi tele. maualuga.

2 Taimi Puupuu

O le feso'ota'iga e fa'aogaina ai le fa'aogaina o feso'ota'iga fa'ainitaneti i luga ole laiga e fa'aitiitia ai le fa'agasologa o feso'ota'iga feso'ota'iga mulimuli ane, fa'atusatusa i le taimi e mana'omia mo le vela po'o le ausa-fesoasoani silane feso'ota'iga ma le fa'atonuina o le fa'aogaina o le irradiation fa'aeletonika, fa'asaoina o le uaea ma le taimi o le gaosiga o le uaea. , aemaise faʻalavelave faʻafuaseʻi O le maeʻa o le misiona, o mea lelei e taua.

3 Tau maualalo

Pe a faatusatusa i le vai mafanafana o fesoʻotaʻiga ma faʻatonuina le faʻaogaina o le eletise eletise, o le tau o le ultraviolet irradiation cable e maualalo, ma o le tele o faiga faʻalavelave e faʻaititia i le gaosiga o le gaosiga, e pei o le tau o felauaiga o uaea semi-maea ma tau o loʻo tutusa.

4 Leai se Osone

Ole maualuga ole galu ole filifili, na'o le fa'auluina ole galu aoga, leai se fa'avevela infrared, maualalo le tau calorific; matua maualalo le aofa'i o fa'avevela va'aia, leai se fa'aleagaina o le malamalama; leai se faʻavelaina o le ultraviolet puʻupuʻu, leai se afaina i le tino o le tagata, leai se ozone. Leai se mana'oga mo le fa'amalieina o le ea, e leai se mana'oga mo se fa'alavelave fa'alavelave fa'afefe ma le osone, na'o le mana'omia e fa'afeso'ota'i se paipa fa'alumaluma la'ititi ma se ili 2kW e fa'aesea ai le asu mole mole maualalo na gaosia i le taimi o le fa'alumaina. . Puipuia a'afiaga o le fa'avevelaina o le malamalama.

5 Laititi Laiti, Faigofie e Faʻapipiʻi

Na'o le fa'aopoopoina o se mamao e tusa ma le 2m i le va o le ulua'i laina gaosiga fa'apipi'i ma le tane vai mafanafana, ma tu'u le masini irradiation i se avanoa o le 2.5 ~ 3 mita le lautele, pe vaapiapi. E mafai ona tu'u le chiller i lea nofoaga.

6 Faigofie ona Faagaioi

Le leoa tatala ma tapunia tunnel fausaga, faigofie e faamama ma ofuina taʻitaʻia, faigofie ona faagaoioia, leai se faiga faigata, e mafai ona faamaeaina e le extruder operator.

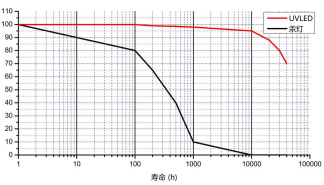

7 Ola Umi ma Tau Tausia Maulalo

O le ola o masini LED e tusa ma le 30,000 itula, ma o le ola o isi masini eletise ma eletise e le maualalo ifo nai lo le ola o oloa eletise ma eletise, e aunoa ma le tausiga faifaipea. Fa'aleleia faifaipea ina ia fa'amama le tioata fa'apitoa, o mea fa'aaoga o solo fale gaosimea ma fa'amama so'o, e mafai ona faia e le tagata fa'afoe. O mea fa'aaogā fa'amalama fa'amalama masani o lamepa UV ma fa'ata, e mana'omia ona sui i se taimi pu'upu'u. E mana'omia fo'i le fa'ainitaneti o le ave fa'aeletonika e fa'atumauina ai le vaega o le tausiga.

8 lanu meamata

O le Fa'atonuga Tulaga Aulelei o le Ea Ambient (GB3095-2012) i totonu o le Industrial Hygiene Standard o lo'o fa'amaonia ai o le tulaga saogalemu o le osone o le 0.15ppm. UVLED UV crosslinking meafaigaluega o le a le maua ai le ozone, ae o meafaigaluega moli mercury masani o le a maua ai se aofaiga tele o le osone. Osone o kesi leaga.

1) Tele ituaiga o talosaga

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Tau maualalo

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Faigofie e faʻapipiʻi

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) Faʻalagolago maualuga

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Fa'atusatusaga o le lelei o le fa'ainitaneti fou fa'apogai o le fa'apogai o feso'ota'iga ma le silane feso'ota'iga:

|

fa'avelaina o le ultraviolet meafaigaluega |

Meafaigaluega feso'ota'i Silane |

Fa'asao tau |

|

|

Tau o meafaitino |

600 kilokalama o otaota i le 90 extruders i le tausaga |

12 tone o otaota i le 90 extruders i le tausaga |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Extruder mana |

O le viscosity o mea e laʻititi, o le eletise e laʻititi, ma o le extruder o le 90 extruder e naʻo le 30KW i le saoasaoa atoa. |

Ole maualuga ole viscosity o meafaitino, maualuga le faʻaaogaina o le eletise, 90 KW faʻavaveina le saoasaoa e manaʻomia |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Pili ole eletise |

E le manaʻomia le faʻamamaina o le extruder |

Fa'amama le extruder mo le afa itula i aso uma |

Faasao 3400 USD i le tausaga |

|

Tau feso'ota'iga |

Ave le 35 sikuea mita e fai ma faʻataʻitaʻiga, o le tau eletise e 80KW mo le 30,000 mita. |

Avea le 35 sikuea mita e fai ma faʻataʻitaʻiga, e manaʻomia le 4 itula mo le 30,000 mita o le vaʻavaʻa faʻafefe, ma e manaʻomia le 200KW o le eletise. |

Save about 7000 USD in electricity every year |

|

Fa'atosina |

I le taimi lava e tasi e fesoʻotaʻi ai ma le extruder, o le faʻapipiʻiina o le insulation e faʻapipiʻi saʻo e aunoa ma se gaioiga lona lua. |

Fua pe fa'ausa mo le itiiti ifo i le 4 itula (e mana'omia se nofoaga fa'apitoa, afi afi) |

Save 8400 USD per year |

|

Tulaga lelei |

Fa'aitiitia le vevela i lalo ifo o le 4%, leai se gel muamua, lamolemole luga |

Fa'aitiitia le vevela, la'ititi fa'a'ese'ese fa'alava e masani ona i ai se mea e le lamolemole ma se gel. |

|

|

Tupe fa'afaigaluega |

Alafua |

Maulalo (potu ausa po'o vaita'ele mafanafana) |

|

|

Fa'aaogāga malosi |

Maulalo (na'o le 10 KW e mana'omia) |

Maualuga (e mana'omia le fa'avevela umi) |

|

|

Tau o le gaosiga |

Maulalo |

Maualuga |

|

|

Taamilosaga o gaosiga |

Puupuu (feso'ota'iga i luga ole laiga) |

Umi (e mana'omia le faiga lona lua) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Fa'atusatusaga o le lelei o le fa'avevelaina fou o le LED ma feso'ota'iga i luga ole laiga ma le moli mercury maualuga maualuga:

|

LED ultraviolet irradiation masini |

Masini fa'avevela molī molī fa'avevela tuai |

|

|

Fa'aaogāga malosi |

Averesi i lalo ole 15 kW ile itula |

80KW i le itula |

|

Tau o le tausiga |

Maulalo |

Maualuga |

|

Saosaoa gaosiga |

Maualuga |

Maulalo |

|

Ola moli |

30000 itula |

400 itula |

|

Mea fa'aaoga |

Leai |

Lamepa, reflector, capacitor |

|

Fa'atosina |

O le extruder e le gata i le saoasaoa maualuga ma e mafai ona gaosia e ala i le kiina o le moli. |

Faʻagesegese le gaosiga o le saoasaoa, maualalo le lelei, otaota o galuega, manaʻomia le faʻamafanafanaina mo le afa itula muamua |

|

Gaioiina ma le avanoa o le fola |

Fa'atonuga faigofie, la'ititi tulagavae, leai se fa'atali |

Faiga fa'alavelave ma le tele o le fola |

|

LED fou irradiation masini sefe 34,000 USD tau eletise. 17,000 USD tau faigaluega ma 8,400 USD consumables i le tausaga nai lo le masini irradiation moli mercury maualuga maualuga. |

||

LED ma moli mercury fa'atusatusaga fa'apitoa

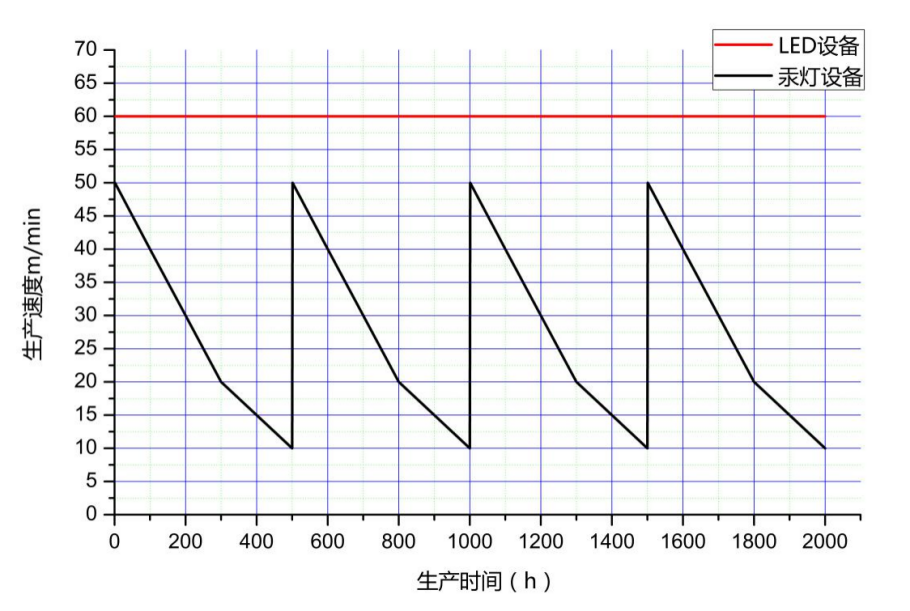

Fa'atusatusa le ola o le moli LED ma le mercury

Fa'atusatusaga o le saoasaoa o le gaosiga i le va o le mercury lamepa irradiation meafaigaluega ma LED irradiation meafaigaluega

UV-LED Iradiation Crosslinking Meafaigaluega Parameter Faatinoga:

- 1. Malosiaga: tolu-vaega lima-uaea faiga (380V + N + eleele)

- 2. Aofa'i masini fa'apipi'i mana: 20kW

- 3. Le pito sili ona lelei o le irradiation eria: 30mm

4. Le umi fa'avevela lelei: 1m

- 5. O loʻo faʻaaogaina e le lamepa le pito i luga o le lalolagi o loʻo faʻaulufaleina mai le malamalama, o le tioata e faʻaaogaina ai le quartz faʻaulufale mai, ina ia maualalo le malosi o le malosi, o le seti moli e faʻaogaina ai tekinolosi faʻafefe vai, ina ia maua ai e le faʻamalama moli o le LED le umi o le auaunaga.

- 6. O le sapalai eletise e faʻaaogaina Taiwan Mingwei e leai se vai, lea e puipuia e le masini masini masini, faʻatasi ai ma le mamafa, vaʻavaʻa puupuu, luga o le taimi nei, luga o le voltage ma le puipuiga o le vevela.

7. E mafai ona fetuutuunai fa'atonuga le mana fa'apitoa mai le 10% -100%, e tusa ai ma mana'oga o tagata fa'atau e fa'afetaui so'o se mana.

- 7. Ola puna malamalama: 30,000 itula (tuuina atu e le gaosi oloa) O le malosi o le malamalama o loʻo faʻaitiitia i le 70% (faʻaitiitia le lelei i le 70%). O le taimi faʻaoga e 30,000 itula, ma o le taimi faʻatusatusa e 6 ~ 10 tausaga.

9. Tele pusa iradiation: 1660mm * 960mm * 1730mm (umi x lautele x maualuga)

Fa'atulagaga o meafaigaluega:

- 1. Leoa le tatalaina ma tapunia alalaupapa fausaga, faigofie ona faagaoioia ma mama;

- 2. O le fa'aogaina o le fa'aogaina o le tagata-masini atamai, fa'amatalaga mata'ituina, ma le fa'aogaina o le mana fa'aogaina ua mae'a uma i luga o le fa'aoga mata pa'i;

- 3. O le galuega fa'atonutonu touchscreen ma le fa'amau amata ona ola fa'atasi;

- 4. O le auala malulu e faʻamafanafanaina e se chiller, ma o le ala faʻasalalau e faia i se mea faʻapitoa mo taavale;

- 5. Fa'aa'a'ese le asu i fafo, fa'ao'o atu ile ala ea i fafo

Fa'atulagaina o meafaigaluega

Saosaoa gaosiga o mea fa'a'ai le polyethylene feso'ota'i

|

Sone 1

|

Sone 2

|

Sone 3

|

Sone 4

|

Sone 5

|

Ulu o masini |

||

|

135℃ |

150℃ |

160℃ |

175℃ |

180℃ |

180℃ |

||

|

Conductor cross section (mm²) |

O le mafiafia fa'amama (mm)

|

Saosaoa gaosiga faanatura (m/min)

|

Fa'aopoopoga o le vevela (%)

|

Deformation tumau |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

E maualalo-asu halogen-sa'oloto irradiation mea gaosiga saoasaoa

|

Sone 1

|

Sone 2

|

Sone 3

|

Sone 4

|

Sone 5

|

Ulu o masini |

||

|

135℃ |

150℃ |

160℃ |

175℃ |

180℃ |

180℃ |

||

|

Conductor cross section (mm²)

|

O le mafiafia fa'amama (mm)

|

Saosaoa gaosiga faanatura (m/min)

|

Fa'aopoopoga o le vevela (%)

|

Deformation tumau |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Faʻamatalaga: Talu ai ona o le faʻaogaina o meafaigaluega ma le gaosiga o gaioiga ma mea uaea o pisinisi eseese e eseese, o le a ese le saoasaoa o le extrusion. O le 90 extruder e le faʻatapulaʻaina.

Fa'apipi'i i luga ole laiga ole masini feso'ota'i feso'ota'iga ole ultraviolet irradiation