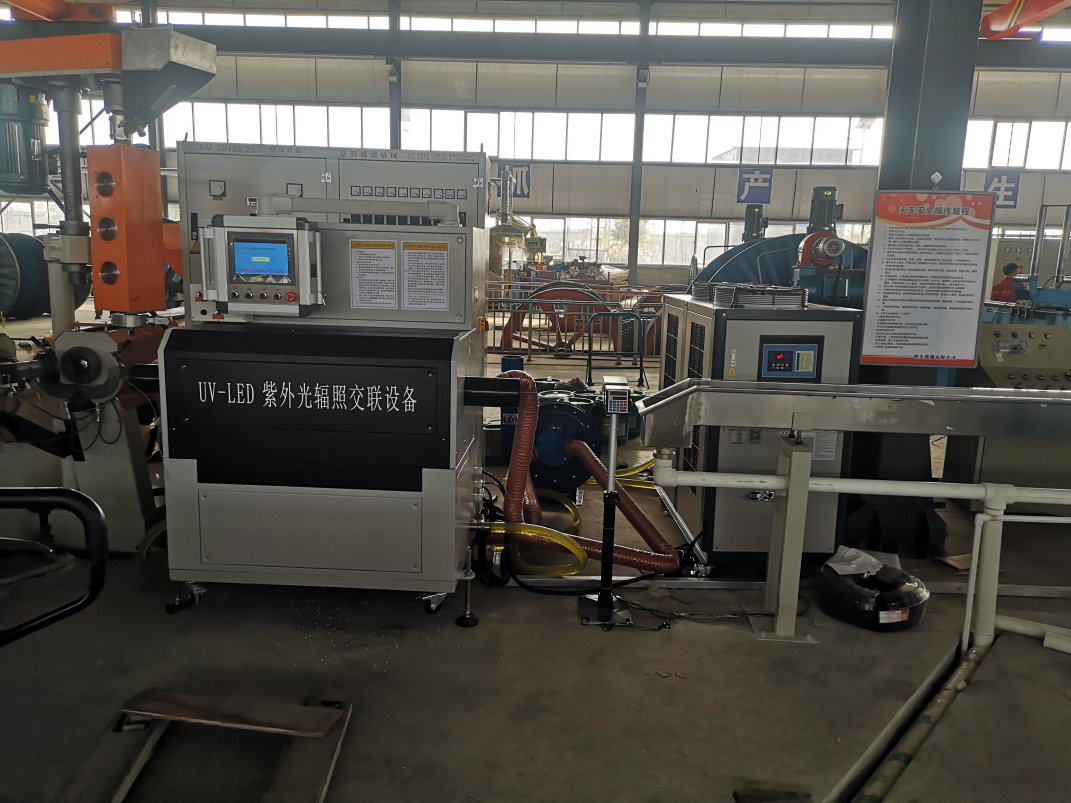

LED Ultraviolet Irradiation Polyolefin Crosslinking Equipment

Product Description

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Hunhu

Ultraviolet LED mudziyo ndiyo yakanyanya kukwirisa ultraviolet radiation sosi munyika, ine simba rakanyanya kushanda (inenge 30%), yakanyanya kunaka yavelength selectivity (hafu-simba wavelength bandwidth 5nm), yakanyanya kukwirira sevhisi (30,000 maawa), infrared Low heat. chizvarwa, hapana chizvarwa che ozone, chakanyanya kukodzera kuchinjika-kubatanidza kurapwa kwemuchinjiko-yakabatana polyolefin nezvimwe zvinhu.

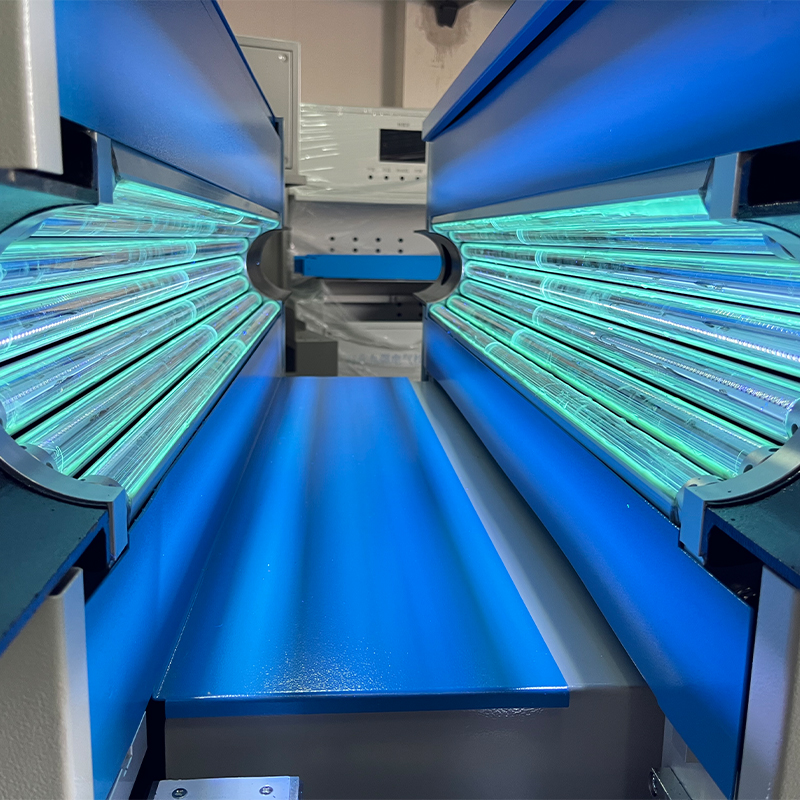

Iyo UV LED sosi inoshandisa patented lens chimiro kuvhenekera pamusoro petambo zvakaenzana uye zvakafanana. Iyo substrate dhizaini inoitwa nekubatanidzwa kweFluent software simulation fluid uye LED junction tembiricha bvunzo, uye LED redunhu bhodhi rakagadzirwa nemusanganiswa wealuminium nitride ceramic uye copper base ine nani kupisa kupisa kuita, uye ine inoshanda zvakanyanya kupisa system.

Iyo UV LED sosi inoshandisa yakagoverwa network simba sosi kutyaira iyo UV LED. Iyo magetsi ekufambisa anoiswa mukati mevacuum potting process kuti ive nechokwadi chekuvimbika kweiyo magetsi. Panguva imwecheteyo, chimiro chemagetsi ekufambisa chinotora chimiro chakamanikana uye chakareba, uye iyo yakareba-yemhando yemwenje sosi ye LED inotora kumashure-kumashure-kumashure yekumisikidza mode yedunhu re LED kuderedza kureba kwewaya. Ziva kuti sosi yemwenje yakabatidzwa, yakadzimwa, uye inodzima mabasa.

Iyo UV LED irradiation polyolefin cross-linking midziyo inotora denderedzwa mhango tunnel chimiro, uye yakashongedzerwa neultraviolet LED mwenje sosi kugadzira mugero wekuvhenekesa dunhu repakati, uye simba rechishandiso rinogona kusetwa zvisina nhanho muhuwandu hwegumi. kusvika 100%.

Kuenzaniswa neyechinyakare mercury mwenje mhando irradiation crosslinking zvishandiso (chinyakare transformer-inotyairwa UVI/UVII uye yemagetsi inotyairwa UVE-I), electron accelerator cross-linking, uye silane cross-linking, ine zvinotevera zvakanakira:

1 Low Energy Consumption

UV LED irradiation polyolefin cross-linking equipment yakaiswa simba yakaenzana ne1/4 yepakutanga ultraviolet irradiation equipment, 1/30 yeelectron accelerator, mvura kana mvura mhute inoda kupisa kwenguva refu, uye mashandisirwo esimba ekudziisa mvura zvakanyanya. high.

2 Nguva Pfupi

Iyo muchinjika-yekubatanidza inotora iyo yepamhepo extrusion muchinjika-yekubatanidza nzira yekudzikisa inozotevera yekubatanidza-yekubatanidza magadzirirwo maitiro, zvichienzaniswa nenguva inodiwa yakabikwa kana mhepo-inobatsira silane kuyambuka-kubatanidza uye kutumwa erekitironi danda irradiation kugadzirisa, kuchengetedza waya uye tambo yekugadzira nguva. , kunyanya emergency Kupedzwa kwemishoni, zvakanakira zvakakosha.

3 Mutengo Wakaderera

Kuenzaniswa nemvura inodziya yekubatanidza-yekubatanidza uye kutumirwa erekitironi beam irradiation processing, mutengo weultraviolet irradiation tambo wakadzikira, uye akawanda akaomesesa maitiro anodzikiswa mukugadzira, semutengo wekufambisa wesemi-akapedza tambo uye inoenderana mutyairi mutengo.

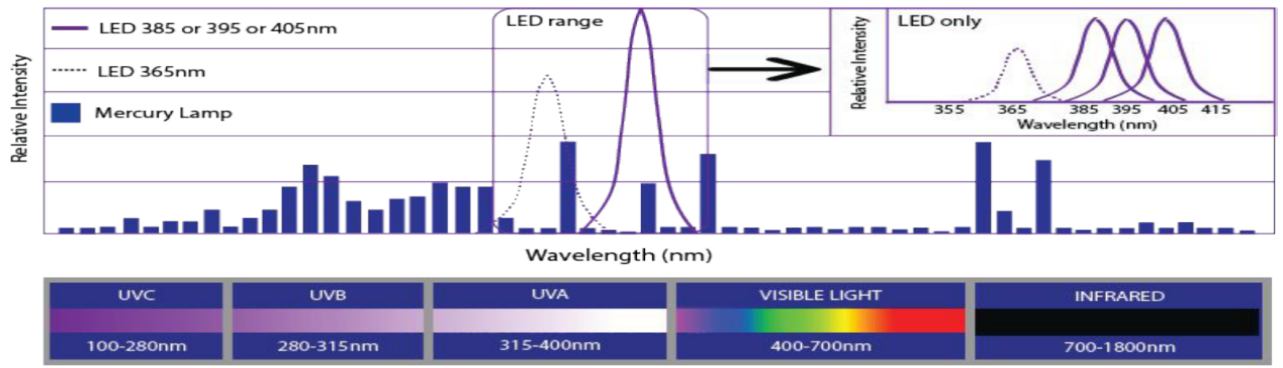

4 Hapana ozoni

Yakanyanya yakakwirira wavelength selectivity, inongoburitsa anobatsira wavelengths, hapana infrared radiation, yakaderera calorific kukosha; yakaderera kwazvo huwandu hwemwaranzi inooneka, hapana kusvibiswa kwechiedza; hapana pfupi-wavelength ultraviolet mwaranzi, hapana kukuvadza kumuviri wemunhu, zero ozone emission. Hapana chikonzero chekutonhora kwemhepo-yepamusoro-simba fan fan, hapana chikonzero cheyakanyanya kuomarara kupisa-kuburitsa uye ozone-inoburitsa mweya duct, inongoda kubatanidza diki-dhiyamita yekupedza pombi uye 2kW fan kuti isabatanidze yakaderera-molecular utsi hunogadzirwa panguva yekupisa extrusion. . Dzivirira mhedzisiro yekuvhenekesa kwechiedza.

5 Diki Size, Nyore Kuisa

Ingo wedzera chinhambwe chingangoita 2m pakati peyekutanga mutsara wekugadzira extruder mold uye tangi yemvura inodziya, uye isa muchina wekuvhenekesa munzvimbo ye2.5 ~ 3 metres muhupamhi, kana nhete. Iyo chiller inogona kuiswa panzvimbo.

6 Zviri Nyore Kushanda

Chinyararire kuvhura uye kuvhara tunnel chimiro, nyore kuchenesa uye kupfeka inotungamira, iri nyore kushanda, hapana yakaoma maitiro, inogona kupedzwa neextruder opareta.

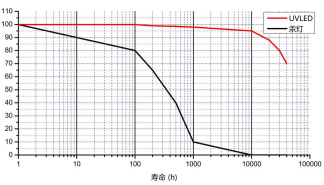

7 Hupenyu Hurefu Uye Mutengo Wakaderera Wekugadzirisa

Upenyu hwemagetsi e LED hunenge maawa makumi matatu, uye hupenyu hwemamwe magetsi nemagetsi hahuna kuderera kudarika hupenyu hwehuwandu hwemagetsi nemagetsi ezvigadzirwa, pasina kugadzirisa nguva dzose. Kugara uchigadzirisa kuchengetedza lens yemaziso yakachena, izvo zvinoshandiswa maindasitiri ekupukuta uye soot cleaners, izvo zvinogona kuitwa nemushandisi. Iyo yechinyakare mwenje yekuvhenekesa michina yekushandisa ndeye UV marambi uye maratidziro, ayo anoda kutsiviwa munguva pfupi. Iyo yemagetsi ray irradiation unit inodiwawo kuchengetedza timu yekuchengetedza.

8 Green

Iyo Ambient Air Quality Standard (GB3095-2012) muIndustrial Hygiene Standard inotaura kuti ozone kuchengetedza mwero i0.15ppm. UVLED UV crosslinking michina haizoburitse ozone, nepo yechinyakare mercury rambi midziyo ichigadzira yakawanda ozone. Ozone gasi rinokuvadza.

1) Yakasiyana-siyana yekushandisa

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Mutengo wakaderera

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Easy kuisa

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) Kuvimbika kwepamusoro

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Kuenzanisa kwemabhenefiti eiyo nyowani LED irradiation cross-linking uye silane cross-linking:

|

LED ultraviolet irradiation midziyo |

Silane crosslinking midziyo |

Kuchengetedza mari |

|

|

Mari yezvinhu |

600 kg yemarara pa90 extruders pagore |

12 matani emarara pa90 extruders pagore |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Extruder power |

Iyo viscosity yezvinhu idiki, mashandisirwo emagetsi idiki, uye extrusion ye90 extruder inongova 30KW pakumhanya kuzere. |

Yakakwira viscosity yezvinhu, kushandiswa kwesimba kwakanyanya, 90 KW yakazara kumhanya extrusion inodiwa |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Mari yemagetsi ekugadzira |

Hapana chikonzero chekuchenesa extruder |

Chenesa extruder kwehafu yeawa zuva rega rega |

Chengetedza 3400 USD pagore |

|

Mutengo wekubatanidza |

Tichitora 35 square metres semuenzaniso, mutengo wemagetsi i80KW we30,000 metres. |

Kutora 35 square metres semuenzaniso, zvinotora 4 maawa e30,000 metres emhepo inoyambuka-yakabatana, uye inoda 200KW yemagetsi. |

Save about 7000 USD in electricity every year |

|

Kubudirira |

Panguva imwe chete kuyambuka-inobatanidza neiyo extruder, iyo extrusion insulation yakanangana netambo pasina yechipiri kugadzirisa |

Yakabikwa kana yakabikwa kweinenge 4 maawa (inoda yakakosha saiti, steam jenareta) |

Save 8400 USD per year |

|

Chigadzirwa chemhando |

Heat shrinkage isingasviki 4%, hapana gel rakapfuura, rakatsetseka |

Kupisa kwakanyanya kupisa, diki diki-section insulation kazhinji ine isiri-yakatsetseka pamusoro uye gel. |

|

|

Equipment investment |

Pakati |

Yakaderera (stem room kana dziva rinodziya) |

|

|

Simba rekushandisa |

Yakaderera (inoda 10 KW chete) |

Yakakwirira (inoda kupisa kwenguva refu) |

|

|

Mutengo wekugadzira |

Low |

High |

|

|

Kutenderera kwekugadzira |

Pfupi (online cross-linking) |

Yakareba (inoda sekondari kugadziriswa) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Kufananidza zvakanakira iyo nyowani LED irradiation uye online kubatana neyekare yakakwirira-kumanikidza mercury rambi:

|

LED ultraviolet irradiation muchina |

Old high pressure mercury lamp irradiation machine |

|

|

Simba rekushandisa |

Avhareji isingasviki 15 kW paawa |

80KW paawa |

|

Mari yekuchengetedza |

Low |

High |

|

Kukurumidza kugadzira |

High |

Low |

|

Hupenyu hwemwenje |

30000 maawa |

400 maawa |

|

Consumables |

Aihwa |

Rambi, reflector, capacitor |

|

Kubudirira |

Iyo extruder haina kugumira pakumhanya kukuru uye inogona kugadzirwa nekubatidza mwenje. |

Kunonoka kugadzira kukurumidza, kushanda kwakaderera, kutambisa kwevashandi, kunoda preheat kwehafu yeawa pamberi |

|

Kushanda uye nzvimbo yepasi |

Kushanda kuri nyore, diki tsoka, hapana kumirira |

Kushanda kwakaoma uye nzvimbo huru yepasi |

|

Muchina mutsva wekuvhenekesa we LED unochengetedza 34,000 USD mari yemagetsi.17,000 USD mari yebasa uye 8,400 USD inobatika pagore pane yekare high-pressure mercury lamp irradiation machine. |

||

LED uye mercury rambi spectral kusiyana

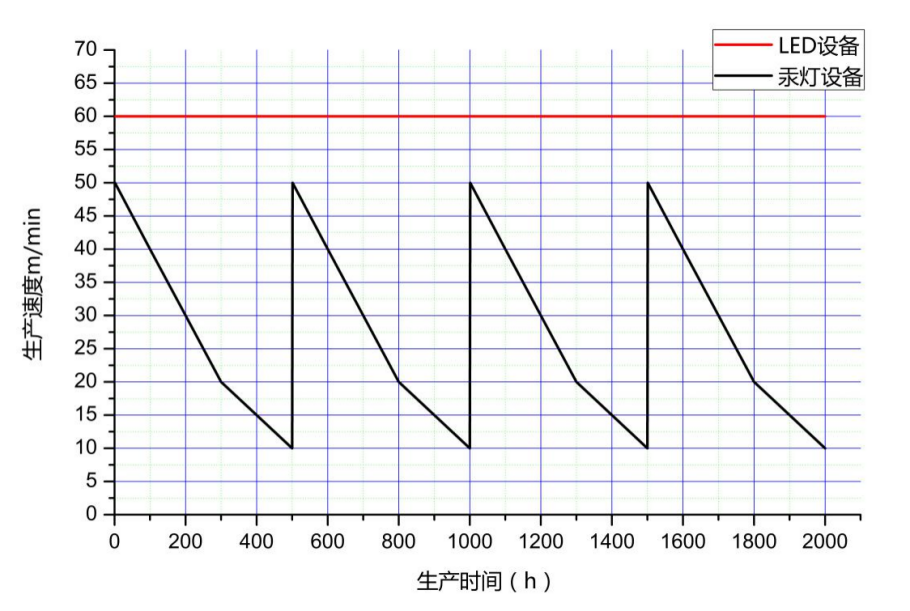

LED uye mercury mwenje hupenyu kuenzanisa

Kuenzanisa kwekugadzira kumhanyisa curve pakati pe mercury rambi irradiation zvishandiso uye LED irradiation michina.

UV-LED Iradiation Crosslinking Equipment Performance Parameters:

- 1. Simba: zvitatu-chikamu cheshanu-waya system (380V + N + pasi)

- 2. Total yakaiswa muchina simba: 20kW

- 3. Iyo yakanakisa dhayamita yeirradiation nzvimbo: 30mm

4. Inoshanda kureba kweradiation: 1m

- 5. Mabheji emwenje anoshandisa nyika yepamusoro inotengeswa kunze kwenyika chiedza, lens inoshandisa quartz inotengeswa kunze, kuitira kuti ine simba rakaderera rekushaya simba, chigadziko chemwenje chinoshandisa tekinoroji yekutonhora kwemvura, kuitira kuti chiedza che LED chive nehupenyu hurefu hwebasa.

- 6. Simba rekushandisa rinotora Taiwan Mingwei mvura isina mvura, iyo inodzivirirwa ne teknolojia yevacuum potting, ine overload, short circuit, pamusoro pezvino, pamusoro pemagetsi uye pamusoro pekudzivirira kwekushisa.

7. Optical power output inogona kugadziriswa kubva ku10% -100%, maererano nezvinodiwa nemutengi kugadzirisa chero simba.

- 7. Chiedza chehupenyu hwehupenyu: maawa 30,000 (akapiwa nemugadziri) Kubuda kwechiedza chechiedza chinoderedzwa kusvika ku70% (kukwanisa kunodonha kusvika ku70%). Nguva yekushandisa i30,000 maawa, uye nguva yekuverenga ndeye 6 ~ 10 makore.

9. Irradiation box size: 1660mm * 960mm * 1730mm (kureba x upamhi x urefu)

Equipment structure features:

- 1. Chinyararire kuvhura uye kuvhara tunnel chimiro, nyore kushanda uye kuchenesa;

- 2. Kushandisa intelligent touch man-machine interface, data monitoring, uye bhatani rekushandisa simba zvigadziriso zvose zvinopedzwa pane touch screen interface;

- 3. The touchscreen control function uye bhatani rinotanga kugarisana zvakasiyana;

- 4. Nzira yekutonhora inotonhodzwa neinotonhora, uye inotenderera inotenderera inogadzirwa ne-antifreeze inokosha yemotokari;

- 5. Nzira yekubvisa utsi hwekunze, inobudiswa kuburikidza nemhepo duct panze

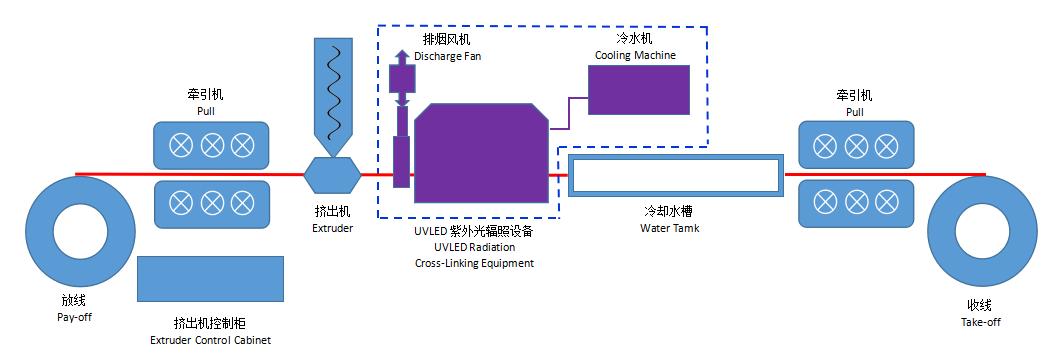

Equipment marongero

Kumhanyisa kwekugadzira kwemuchinjikwa-yakabatana polyethylene irradiated material

|

Zone 1

|

Zone 2

|

Zone 3

|

Zone 4

|

Zone 5

|

Musoro wemuchina |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

Insulation nominal ukobvu(mm)

|

Kumhanya kwekugadzira zvakasikwa (m/min)

|

Kuwedzera kupisa (%)

|

Permanent deformation |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Yakaderera-utsi halogen-isina irradiation zvinhu kukurumidza kugadzira

|

Zone 1

|

Zone 2

|

Zone 3

|

Zone 4

|

Zone 5

|

Musoro wemuchina |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

Insulation nominal ukobvu(mm)

|

Kumhanya kwekugadzira zvakasikwa (m/min)

|

Kuwedzera kupisa (%)

|

Permanent deformation |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Remarks: Nekuti iyo extrusion midziyo uye maitiro ekugadzira uye tambo zvinhu zvemabhizinesi akasiyana zvakasiyana, iyo extrusion kumhanya ichave yakasiyana. Iyo 90 extruder haina kuganhurirwa.

Pa-saiti kuisirwa kwe LED ultraviolet irradiation cross-linking muchina