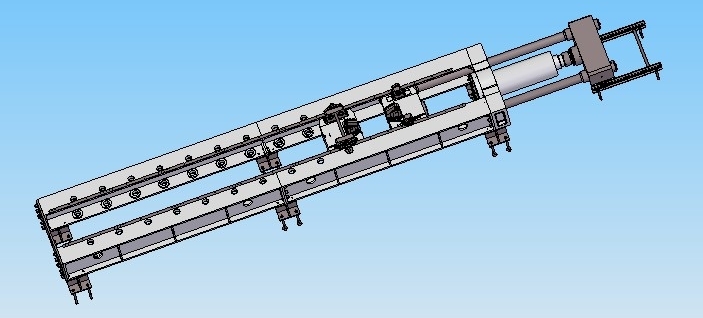

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Product Description

TXWL-600 electro-hydraulic servo horizontal tensile yekuyedza muchina inotora yakachinjika furemu chimiro, imwe tsvimbo kaviri-inobata piston silinda ine simba rekuyedza, uye komputa inodzora system inoona iyo otomatiki kutonga kweye bvunzo nekudzora servo valve uye zvimwe zvikamu, bvunzo. dhata inounganidzwa nemazvo nekuremerwa sensor uye kuendeswa kumakombuta, sisitimu inoongorora otomatiki, inogadzirisa uye inochengeta mhinduro dzebvunzo, uye printa inogona kudhinda zvakananga chirevo chebvunzo chinodiwa. Muchina uyu unonyanya kushandiswa kuyedza tambo yesimbi waya, kugadzirwa kwemazuva ano kwekutsvagisa kwesainzi uye kudzidzisa uye mamwe maindasitiri kuti asangane nezvinodiwa zveiyo yakakodzera bvunzo michina.

Muchina Tsanangudzo

1.Host system

Chikamu chikuru chemuchina chinonyanya kuumbwa nemuchina mukuru furemu, chigaro chemafuta silinda, silinda yemafuta, danda rinofamba, kumberi uye kumashure chuck chigaro uye mutoro sensor. Inogona kuita tensile bvunzo ine yakanyanya kuremerwa ye600kN pane sampuli.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Nzvimbo yekuyedza yakashongedzerwa nevhavha yekudzivirira, iyo inogona kunyatso chengetedza kuchengetedzwa kwevashandi vebvunzo.

2.Oil source system

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Electrical Chikamu

Kudzora kwemagetsi kwakarongedzerwa munzvimbo yekuyedza mashandiro, uye kune yakanyatso dhizainirwa mashandiro ekuita kuti marudzi ese ekushanda ajeke pakatarisa. Izvo zvikamu zvemagetsi ndezvemhando yepasirese ine mukurumbira, nekuita kwakagadzikana uye yakavimbika mhando.

Software System:

(1) Zvichienderana neWindows XP inoshanda papuratifomu ine zvinorongwa mabasa, yakaenzana-chiyero bvunzo simba rekudzora, yakaenzana-mwero wekutamisa kudzora, kuyedza simba rekubata, kutamiswa kubata uye mamwe maitiro ebvunzo anogona kusanganiswa pakuda kusangana nezvinodiwa zveakasiyana nzira dzekuyedza. kusvika pamwero mukuru, uye kuona akasiyana data kuratidza, curve kudhirowa, kugadzirisa data, kuchengetedza uye kudhinda mabasa anodiwa pabvunzo.

(2) Tumira chiratidzo chekutonga kune servo valve kuburikidza nekombuta kuti udzore kuvhurwa uye kutungamira kwevhavhavha yevhavha, nokudaro uchidzora kuyerera muhumburumbira, uye kuona kutonga kweakaenzana-chiyero chekuedza simba, kuenzana-chiyero kusimuka, nezvimwewo, nezvimwe. .

(3) Yakashongedzerwa maviri akavharwa-loop ekudzora zvishwe zvekuyedza simba uye kutamiswa.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Iyo huru interface ine mabasa ese ekushanda kwezuva nezuva kwebvunzo, senge sampuli yekupinda ruzivo, sarudzo yemuenzaniso, curve kudhirowa, kuratidza data, kugadzirisa data, kuongorora data, bvunzo mashandiro, nezvimwe. fast.

(6) Iyo data inogona kubuditswa kune anodhinda kudhinda bvunzo repoti.

(7) System hierarchical management, masisitimu ma paramita ese akavhurika kune nyanzvi vashandisi, kuve nechokwadi kuchinjika uye kuvimbika kweiyo system.

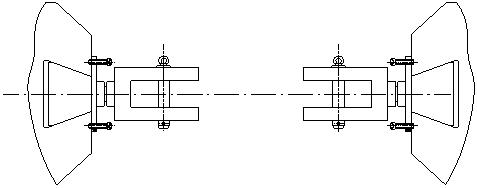

4.Test Accessories

Yakashongedzerwa newaya tambo yekuyedza zvishongedzo (ona pazasi) uye zvimwe zvishongedzo zvinogadzirwa zvinoenderana nechiyero chinopihwa nemushandisi kana zvinodikanwa zvekusimba zvemuenzaniso.

5.Safety Protection Devices

(1) Kudzivirirwa kwekuremerwa kana simba rekuyedza richipfuura 2% kusvika 5% yehukuru hwekuyedza simba kana kukosha kwakaiswa.

(2) Kudzivirirwa kwekurohwa kana piston inofamba ichienda kunzvimbo inogumira.

(3) Iine tembiricha yemafuta, nhanho yemvura uye mafuta anodzivirira kudzivirira uye zviratidzo.

(4) Nzvimbo yekuedza ine chivharo chekudzivirira kudzivirira sampuli kubva pakuputsika nekudonha.

(5) Kana emergency yaitika, tinya bhatani rekumisa emergency pane control cabinet zvakananga

Technical Parameter

1.Maximum test force: 600kN

2.Test simba rekuyera chiyero: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile bvunzo nzvimbo (kunze kwepiston sitiroko): 20mm ~ 12000mm

5.Piston sitiroko: 1000mm

6.Maximum kushanda nokukurumidza kwepiston: 100 mm / min

7.Deformation extensometer kururama: 0.01mm

8.Dimension yemuchina mukuru(mm): 16000(L) x 1300(W) x 1000(H) (kunze kwevhavha yekudzivirira)