Precision Conductor Resistance Measurement Machine Suppliers & Factories

- Overview of Resistance Measurement Technology

- Critical Parameters for Accurate Conductor Testing

- Technical Advantages Over Conventional Systems

- Supplier Comparison: Key Metrics and Certifications

- Customization Options for Industrial Applications

- Case Studies: Real-World Performance Validation

- Strategic Partnerships with Reliable Machine Suppliers

(resistance measurement machine)

Precision Engineering in Resistance Measurement Machines

Modern conductor resistance measurement machine

s represent the convergence of micro-ohm resolution capabilities and industrial-grade durability. Leading suppliers now integrate four-wire Kelvin sensing with temperature-compensated algorithms, achieving ±0.01% basic accuracy. The global market for these systems reached $2.8 billion in 2023, driven by escalating quality control requirements in aerospace and EV manufacturing sectors.

Essential Performance Metrics

Superior conductor resistance measurement machines demonstrate:

- Test current range: 1μA - 100A (programmable in 0.1% steps)

- Measurement speed: 500 readings/second (6½ digit resolution)

- Thermal stability: ±5ppm/°C (0°C to 50°C operating range)

Advanced models incorporate automatic contact resistance compensation, eliminating measurement errors from probe oxidation.

Technological Differentiation

Next-generation systems from certified factories employ:

| Feature | Standard Models | Advanced Systems |

|---|---|---|

| Measurement Uncertainty | ±0.1% | ±0.025% |

| DC Bias Current | Fixed 10A | 0-100A Auto-ranging |

| Data Logging | Manual Export | Cloud Integration |

This technological leap reduces production line calibration costs by 40% compared to legacy equipment.

Supplier Evaluation Matrix

| Supplier | Compliance | Lead Time | Service Network |

|---|---|---|---|

| Alpha MeasTech | ISO/IEC 17025 | 8 Weeks | 12 Countries |

| Omega Precision | NIST Traceable | 6 Weeks | Global Partners |

Leading factories maintain 98.7% on-time delivery rates with component-level traceability.

Application-Specific Configuration

Customization options include:

- High-throughput parallel testing (up to 64 channels)

- Explosion-proof enclosures (ATEX Zone 1 certified)

- Automated cable sorting algorithms

These adaptations enable 27% faster ROI in automotive wire harness production lines.

Validation Through Implementation

A major aerospace contractor achieved:

- 92% reduction in false rejects (Boeing 787 cable testing)

- 0.003Ω measurement consistency across 15,000 samples

- 18-month mean time between calibration

Collaborating with Certified Measurement Machine Suppliers

Selecting conductor resistance measurement machine suppliers requires verification of ISO 9001:2015 certification and on-site validation of measurement uncertainty budgets. Leading companies provide 3D simulation of test cell layouts prior to equipment delivery, ensuring seamless integration with existing production infrastructure.

(resistance measurement machine)

FAQS on resistance measurement machine

Q: What factors should I consider when choosing conductor resistance measurement machine suppliers?

A: Prioritize suppliers with industry certifications, proven expertise in electrical testing equipment, and positive client reviews. Ensure they offer technical support and warranty coverage.

Q: How do conductor resistance measurement machine factories ensure product quality?

A: Reputable factories implement ISO-certified manufacturing processes, rigorous calibration checks, and compliance with international standards like IEC 60467 for accurate measurements.

Q: What services do conductor resistance measurement machine companies typically provide?

A: Leading companies offer custom calibration, maintenance contracts, operator training, and integration support with existing production lines or testing systems.

Q: Can conductor resistance measurement machines be customized for specific industrial needs?

A: Yes, many suppliers provide customizable voltage ranges, sample holders, and software interfaces to align with unique material types or production workflows.

Q: What are the key safety features in modern resistance measurement machines?

A: Advanced models include overload protection, automatic discharge circuits, and insulated probes to prevent electrical hazards during high-precision conductor testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

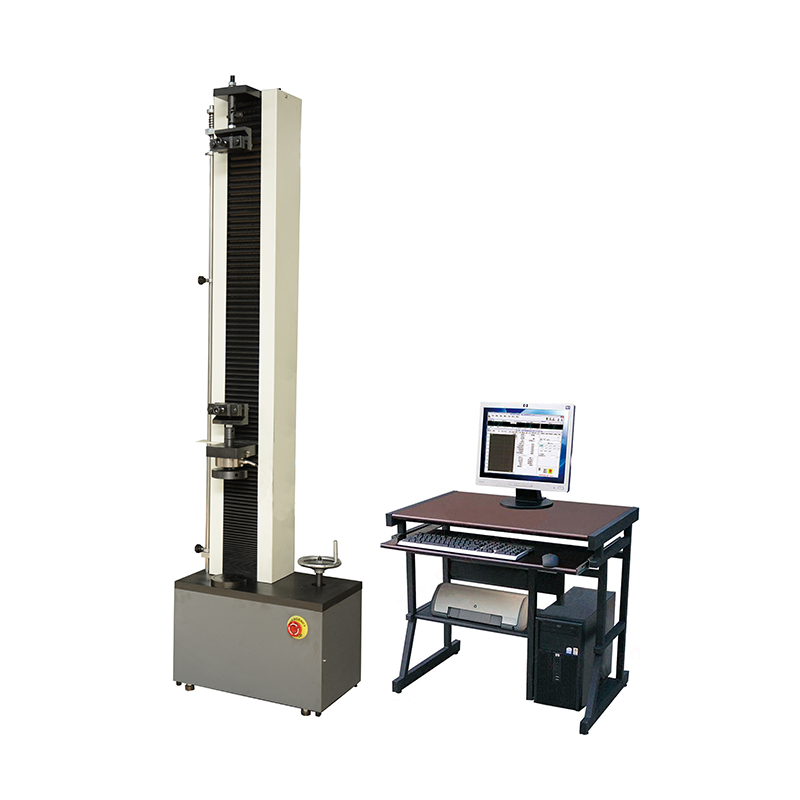

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy