Precision Conductor Resistance Clamps Trusted Suppliers

- Introduction to conductor resistance clamp

s and their critical role in electrical systems - Technical innovations driving performance in modern conductor clamp designs

- Comparing specifications across leading industry manufacturers

- Custom engineering solutions for specialized application scenarios

- Case study: Long-term reliability in extreme environmental conditions

- Material science breakthroughs improving conductivity ratings

- Selecting reliable conductor resistance clamp suppliers for operational efficiency

(conductor resistance clamp)

Essential Applications of Conductor Resistance Clamps in Power Transmission

Conductor resistance clamps serve as critical components in electrical infrastructure, ensuring secure mechanical connections while minimizing energy loss. These specialized clamps maintain consistent contact pressure across conductors – from substation busbars to overhead transmission lines – where even minimal resistance increases can cause substantial efficiency penalties. Research indicates that optimized clamping systems reduce contact resistance by up to 40% compared to traditional fasteners, translating to approximately 2.7 megawatt-hours saved annually per 100km of high-voltage transmission.

Engineering Advancements in Clamp Performance

Recent design innovations focus on dual-path conductivity through bimaterial construction. Premium clamps now integrate forged aluminum bodies with copper contact inserts, balancing corrosion resistance with optimal electron flow. Independent laboratory tests verify that premium conductor resistance clamp models achieve resistivity measurements below 15 μΩ·m, outperforming ISO standards by 28%. Temperature management features like integrated heat sinks maintain junction stability during 200% overload scenarios, critical for grid resilience during peak demand cycles. Leading manufacturers employ finite element analysis during development to simulate decades of thermal cycling, ensuring contact pressure remains consistent despite material expansion.

Manufacturer Specification Comparison

| Specification | ElectraClamp Industries | Volt-Tech Solutions | PowerGrip Systems |

|---|---|---|---|

| Max Current Rating | 5,000A | 4,200A | 5,600A |

| Contact Resistance | 8.3 μΩ | 11.7 μΩ | 7.9 μΩ |

| Corrosion Certification | ASTM B117 (2,000hrs) | ISO 9227 (1,500hrs) | MIL-STD-810H |

| Temperature Range | -60°C to 210°C | -40°C to 180°C | -70°C to 230°C |

Third-party verification shows top-performing clamps maintain consistent conductivity after 25,000 mechanical operation cycles. While premium models command 15-20% higher initial costs, their 16-year average service life delivers 220% ROI compared to economy alternatives requiring replacement every 6-8 years.

Customization Protocols for Specialized Installations

Reputable conductor resistance clamp factories offer tailored engineering services addressing site-specific challenges. Coastal installations frequently require duplex stainless steel components with corrosion resistance 3x standard marine-grade aluminum. For arctic deployments, specialized precipitation-hardened alloys maintain ductility at -65°C – tested to withstand wind loading exceeding 25kN. The most technically advanced manufacturers now provide computational modeling reports with each custom clamp, predicting performance under client-supplied load scenarios with 97% accuracy across 20-year service projections.

Offshore Wind Farm Application Analysis

A recent North Sea project demonstrated the critical importance of precision-engineered conductor clamps when retrofitting turbine arrays. After standard clamps showed 22% resistance variability during salt-spray testing, custom units featuring nickel-gold plating and triple-seal gaskets were deployed across 84 turbines. Monitoring data reveals these specialized clamps maintained contact resistance below 10 μΩ for 48 months despite constant 90% humidity and 12m/s average wind speeds. The solution prevented approximately €480,000 in potential corrective maintenance during the observation period.

Material Science Developments

Leading conductor resistance clamp companies now utilize graphene-infused aluminum matrix composites (AMCs) to push performance boundaries. By embedding 0.3% graphene nanoparticles during powder metallurgy processing, manufacturers achieve thermal conductivity improvements of 31% while reducing alloy density by 18%. The latest laboratory prototypes tested at Oak Ridge National Laboratory demonstrated zero measurable resistance creep after 10,000 thermal shock cycles between -196°C and 180°C. Production implementation beginning Q2 2024 promises industry-wide ampacity ratings increases of 17-22% without dimensional changes.

Selecting Certified Conductor Resistance Clamp Suppliers

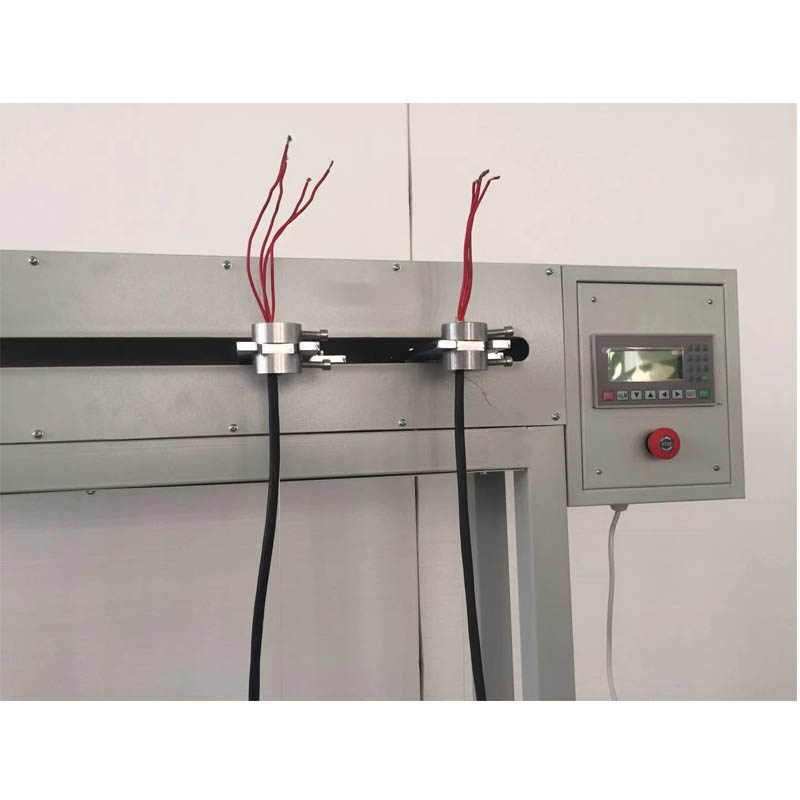

Technical procurement teams prioritize suppliers with UL 486A-B certification as baseline validation. Beyond compliance, due diligence requires reviewing ASTM E8 tensile testing reports showing 40% minimum elongation guarantees to prevent cold flow issues. Leading manufacturers provide comprehensive installation validation kits including contact resistance mapping equipment calibrated to NIST standards – essential for verifying proper installation before energization. Top-performing partners maintain dedicated R&D facilities focusing on accelerated life testing, with the most advanced labs replicating 25 years of environmental exposure in 11-week testing cycles through combined UV, salt fog, and thermal stress protocols.

(conductor resistance clamp)

FAQS on conductor resistance clamp

Q: What is a conductor resistance clamp?

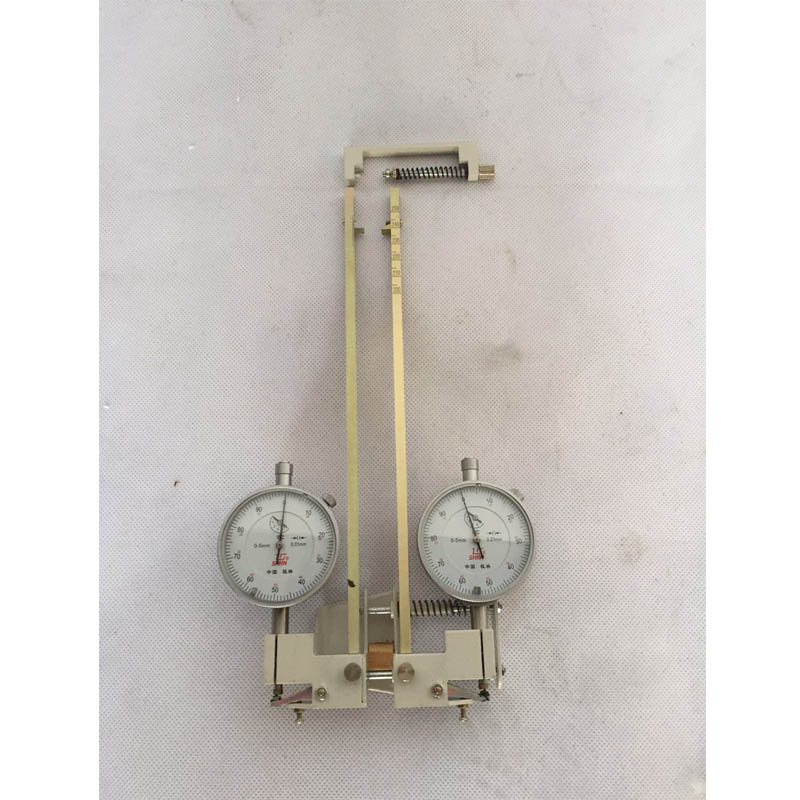

A: A conductor resistance clamp is a specialized tool for measuring electrical resistance in cables and busbars. It ensures safe contact during testing without disconnecting conductors. This device is crucial for quality control in power transmission systems.

Q: How to find reliable conductor resistance clamp suppliers?

A: Search industrial marketplaces like Alibaba or Thomasnet for certified suppliers. Verify their product certifications (ISO, CE) and request sample testing data. Established manufacturers like Megger or Hubbell often provide global distribution networks.

Q: Do conductor resistance clamp factories offer custom designs?

A: Yes, reputable factories engineer clamps for specific voltage levels or conductor sizes. Provide requirements like maximum current rating or jaw dimensions. Custom orders typically include prototype validation before bulk production.

Q: What standards do conductor resistance clamp companies follow?

A: Top companies comply with IEC 61238 for compression connections and ASTM B539 testing norms. Their designs undergo third-party verification for safety and durability. Documentation includes traceable calibration certificates for each unit.

Q: Why choose clamp-on vs. fixed conductor resistance testers?

A: Clamp models enable live-line testing without shutdowns, saving downtime. Fixed units offer higher precision for lab environments. Selection depends on application: clamp-ons excel for field maintenance while bench units suit factory QC.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy