jan . 28, 2025 06:16

Back to list

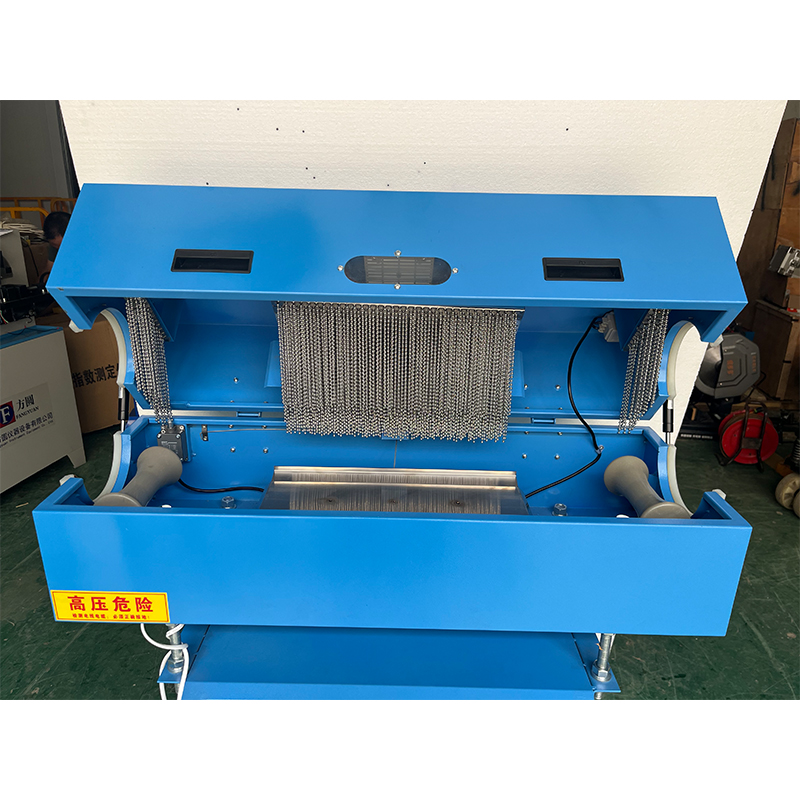

HW-II Constant Temperature Water Bath

Customizing a 15-ton tensile tester offers unique advantages for industries that require precise tensile strength assessments of materials and components. These testers are crucial for research and development, ensuring quality control, and maintaining compliance with industry standards.

Moreover, the integration of innovative technology, such as load cells with high precision and modern actuators, enhances the accuracy and functionality of custom testers. These components are chosen specifically for their performance in real-world conditions, which may involve exposure to various environmental factors or repeated testing cycles. Authoritativeness in producing custom tensile testers is established through years of research, development, and feedback from key industry players. Manufacturers often collaborate with leading research institutions and industry experts to advance the development of these systems, ensuring that they remain at the forefront of testing technology. Real-world experience from users of custom 15-ton tensile testers highlights their practicality and necessity in industrial settings. For instance, a manufacturer of aerospace components reported a significant improvement in their material testing capabilities, attributing this to the precision and reliability of their custom tester. This not only boosted their product quality but also enhanced client trust and satisfaction. The operating ease of custom tensile testers is another highlight. Modern models are designed with user-friendly interfaces that reduce the training burden and increase the efficiency of material testing teams. This ease of use translates to higher productivity, as personnel can quickly adapt and perform tests without extensively consulting manuals or requiring technical support. Furthermore, maintenance of these systems is simplified through advanced diagnostics and alerts for calibration checks, ensuring long-term accuracy without frequent downtime. These features provide added value, reinforcing the investment by delivering consistent and reliable performance throughout the equipment's lifecycle. In conclusion, investing in a custom 15-ton tensile tester is a strategic decision for any industry seeking to elevate their material testing capabilities. Its advanced customization, expert engineering, and proven reliability offer a competitive advantage in quality assurance and innovation. Companies adopting these systems benefit from enhanced testing accuracy, operational efficiency, and sustained product excellence, fostering trust and authority in their respective markets.

Moreover, the integration of innovative technology, such as load cells with high precision and modern actuators, enhances the accuracy and functionality of custom testers. These components are chosen specifically for their performance in real-world conditions, which may involve exposure to various environmental factors or repeated testing cycles. Authoritativeness in producing custom tensile testers is established through years of research, development, and feedback from key industry players. Manufacturers often collaborate with leading research institutions and industry experts to advance the development of these systems, ensuring that they remain at the forefront of testing technology. Real-world experience from users of custom 15-ton tensile testers highlights their practicality and necessity in industrial settings. For instance, a manufacturer of aerospace components reported a significant improvement in their material testing capabilities, attributing this to the precision and reliability of their custom tester. This not only boosted their product quality but also enhanced client trust and satisfaction. The operating ease of custom tensile testers is another highlight. Modern models are designed with user-friendly interfaces that reduce the training burden and increase the efficiency of material testing teams. This ease of use translates to higher productivity, as personnel can quickly adapt and perform tests without extensively consulting manuals or requiring technical support. Furthermore, maintenance of these systems is simplified through advanced diagnostics and alerts for calibration checks, ensuring long-term accuracy without frequent downtime. These features provide added value, reinforcing the investment by delivering consistent and reliable performance throughout the equipment's lifecycle. In conclusion, investing in a custom 15-ton tensile tester is a strategic decision for any industry seeking to elevate their material testing capabilities. Its advanced customization, expert engineering, and proven reliability offer a competitive advantage in quality assurance and innovation. Companies adopting these systems benefit from enhanced testing accuracy, operational efficiency, and sustained product excellence, fostering trust and authority in their respective markets.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy