Jan . 17, 2025 04:04

Back to list

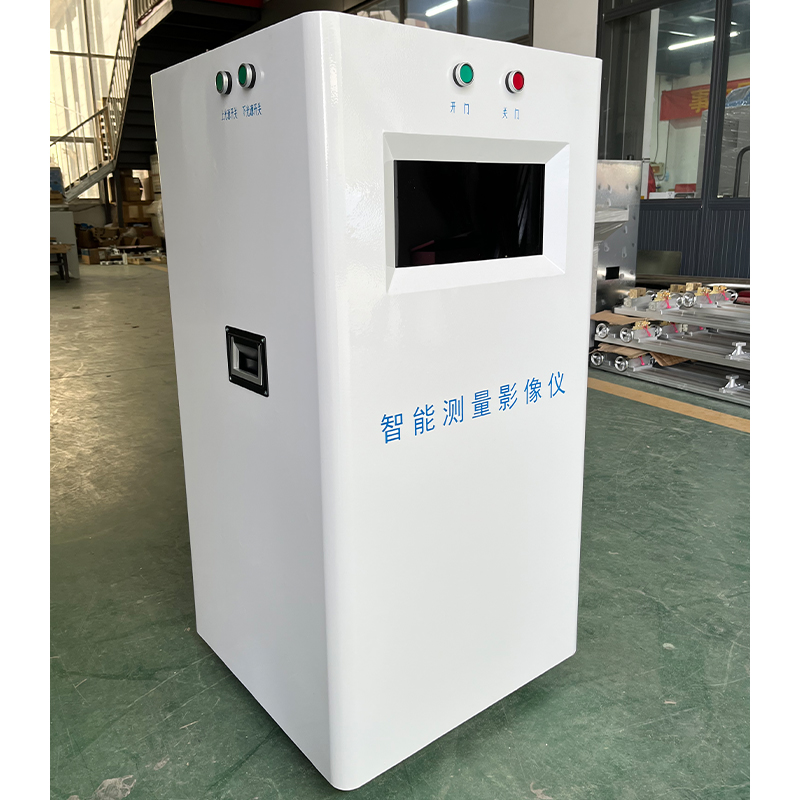

projector measuring machine company

For industries that demand precision in measurement and quality control, the optical profile projector emerges as an indispensable tool. The optical profile projector, often overlooked, serves as a cornerstone in ensuring meticulous accuracy across various sectors such as manufacturing, automotive, and aerospace.

Authoritativeness Optical profile projectors have earned their place as authoritative tools in metrology. Institutions and organizations involved in standardization and precision engineering often rely on these projectors for calibration and verification tasks. By benchmarking components against established standards, optical profile projectors ensure adherence to stringent specifications. The instrument's reliability is further amplified by its non-contact measurement capabilities, ensuring that delicate components remain unaffected during inspection, a quality that underscores its authority in critical evaluations. Trustworthiness When it comes to quality assurance, trust is paramount. The optical profile projector has established itself as a trustworthy ally, offering consistent and repeatable measurements. Its robustness and reliability across varied environmental conditions make it a favored choice among quality inspectors. Many manufacturers have integrated optical profile projectors into their quality assurance protocols, not only to maintain high standards but to instill confidence in their clients regarding the thoroughness of their quality checks. The transparency it brings to the measurement process is invaluable in fostering trust with stakeholders. In conclusion, the optical profile projector is more than just a tool; it is a vital component in the precision measurement ecosystem. Its application extends beyond merely identifying defects; it plays an essential role in maintaining the overall integrity and quality of products across critical industries. As technology continues to evolve, the capabilities of optical profile projectors will only enhance, reinforcing their indispensability in precision engineering and quality control processes.

Authoritativeness Optical profile projectors have earned their place as authoritative tools in metrology. Institutions and organizations involved in standardization and precision engineering often rely on these projectors for calibration and verification tasks. By benchmarking components against established standards, optical profile projectors ensure adherence to stringent specifications. The instrument's reliability is further amplified by its non-contact measurement capabilities, ensuring that delicate components remain unaffected during inspection, a quality that underscores its authority in critical evaluations. Trustworthiness When it comes to quality assurance, trust is paramount. The optical profile projector has established itself as a trustworthy ally, offering consistent and repeatable measurements. Its robustness and reliability across varied environmental conditions make it a favored choice among quality inspectors. Many manufacturers have integrated optical profile projectors into their quality assurance protocols, not only to maintain high standards but to instill confidence in their clients regarding the thoroughness of their quality checks. The transparency it brings to the measurement process is invaluable in fostering trust with stakeholders. In conclusion, the optical profile projector is more than just a tool; it is a vital component in the precision measurement ecosystem. Its application extends beyond merely identifying defects; it plays an essential role in maintaining the overall integrity and quality of products across critical industries. As technology continues to evolve, the capabilities of optical profile projectors will only enhance, reinforcing their indispensability in precision engineering and quality control processes.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy