جنوری . 20, 2025 14:35

Back to list

FY450 High Temperature Pressure Test Chamber

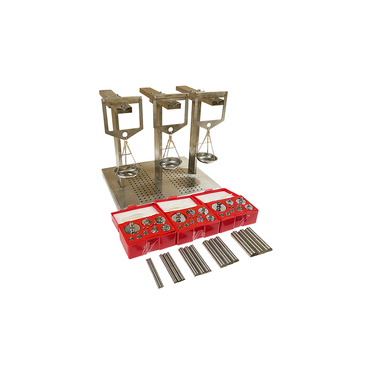

Tensile tester grips are essential components in the realm of material testing, offering precision and reliability for a myriad of applications across various industries. These gripping devices play a critical role in ensuring that tensile tests yield accurate and reproducible results, which are vital for verifying material properties like strength, ductility, and elasticity. The market for tensile tester grips encompasses a wide array of designs, each tailored to accommodate specific materials and test demands. From pneumatic to manual, wedge to button grips, understanding the nuances of each type and their application can significantly enhance testing outcomes and lab efficiency.

Trustworthiness in the context of tensile tester grips is underpinned by the reputation of manufacturers and their history of delivering reliable and durable products. Leading manufacturers often provide extensive documentation, training, and support to help users achieve the best results from their grips and testing equipment. Furthermore, reviews and feedback from other users and industry experts can offer valuable insights into the performance and reliability of different grips, aiding in the selection process. When it comes to product innovation, the evolution of tensile tester grips is spurred by advances in technology and materials science. New grip designs often incorporate ergonomic features that simplify operation and reduce physical strain on operators. Additionally, the integration of digital technology and automation in testing equipment has led to the development of grips that can be easily adjusted and controlled via software, enhancing precision and repeatability. Manufacturers are also exploring novel materials such as composites and engineered polymers to produce grips that combine strength, durability, and reduced weight. Ultimately, choosing the right tensile tester grips is a critical decision that can impact the quality and reliability of material testing results. Factors such as compatibility with existing testing systems, ease of use, and adaptability to different test scenarios should be considered. By leveraging their detailed experience, deep-seated expertise, adherence to authoritative guidelines, and a trustworthy reputation, professionals in the field can select the best grips for their specific needs, ensuring accurate and efficient testing processes.

Trustworthiness in the context of tensile tester grips is underpinned by the reputation of manufacturers and their history of delivering reliable and durable products. Leading manufacturers often provide extensive documentation, training, and support to help users achieve the best results from their grips and testing equipment. Furthermore, reviews and feedback from other users and industry experts can offer valuable insights into the performance and reliability of different grips, aiding in the selection process. When it comes to product innovation, the evolution of tensile tester grips is spurred by advances in technology and materials science. New grip designs often incorporate ergonomic features that simplify operation and reduce physical strain on operators. Additionally, the integration of digital technology and automation in testing equipment has led to the development of grips that can be easily adjusted and controlled via software, enhancing precision and repeatability. Manufacturers are also exploring novel materials such as composites and engineered polymers to produce grips that combine strength, durability, and reduced weight. Ultimately, choosing the right tensile tester grips is a critical decision that can impact the quality and reliability of material testing results. Factors such as compatibility with existing testing systems, ease of use, and adaptability to different test scenarios should be considered. By leveraging their detailed experience, deep-seated expertise, adherence to authoritative guidelines, and a trustworthy reputation, professionals in the field can select the best grips for their specific needs, ensuring accurate and efficient testing processes.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy