3 月 . 06, 2025 16:09

Back to list

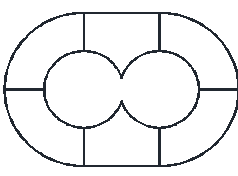

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

When considering the vast and complex world of manufacturing machinery, cable cutting machines stand out as pivotal tools ensuring precise operations across various industries. Selecting the right cable cutting machine manufacturer requires an understanding of several core principles that uphold the manufacturer's commitment to quality, precision, and innovation.

When navigating the selection process, potential buyers should assess the product range of each manufacturer. Leaders in the field offer a diverse array of machines tailored to various needs, whether for small-scale businesses or large industrial outfits. They provide customizable solutions to meet specific operational requirements, ensuring that clients receive machines that integrate seamlessly into existing production lines. Equally important is evaluating the technological advancements incorporated into these machines. Top-tier manufacturers employ innovations such as automated adjustment systems, computer numerical control (CNC) capabilities, and Internet of Things (IoT) integration to enhance performance and data tracking. Machines that feature touch-screen interfaces, programmable settings, and remote monitoring capabilities offer enhanced usability while promising minimal downtime and easy troubleshooting. Manufacturers that excel also commit to sustainable practices. As environmental concerns grow, choosing a company with green manufacturing processes is crucial. This includes using recyclable materials, reducing energy consumption, and committing to lowering waste emissions. Sustainable practices reflect a manufacturer's responsibility not only to their clients but to the planet, aligning with modern business values and customer expectations. Finally, cost-efficiency is essential, but it should never compromise quality. While competitive pricing is important, the value proposition of purchasing a machine extends beyond the initial costs. The right machine should promise longevity, reduced maintenance costs, and enhanced productivity, ultimately providing a return on investment that justifies the expenditure. In conclusion, selecting a cable cutting machine manufacturer involves evaluating experience, expertise, authoritativeness, and trustworthiness. Buyers should research thoroughly, considering not just the machines themselves but the comprehensive package offered by the manufacturer, from customer support to sustainability practices. By doing so, businesses will not only secure machinery that effectively meets their needs but will also forge a partnership with a company that supports their success and growth in the long term.

When navigating the selection process, potential buyers should assess the product range of each manufacturer. Leaders in the field offer a diverse array of machines tailored to various needs, whether for small-scale businesses or large industrial outfits. They provide customizable solutions to meet specific operational requirements, ensuring that clients receive machines that integrate seamlessly into existing production lines. Equally important is evaluating the technological advancements incorporated into these machines. Top-tier manufacturers employ innovations such as automated adjustment systems, computer numerical control (CNC) capabilities, and Internet of Things (IoT) integration to enhance performance and data tracking. Machines that feature touch-screen interfaces, programmable settings, and remote monitoring capabilities offer enhanced usability while promising minimal downtime and easy troubleshooting. Manufacturers that excel also commit to sustainable practices. As environmental concerns grow, choosing a company with green manufacturing processes is crucial. This includes using recyclable materials, reducing energy consumption, and committing to lowering waste emissions. Sustainable practices reflect a manufacturer's responsibility not only to their clients but to the planet, aligning with modern business values and customer expectations. Finally, cost-efficiency is essential, but it should never compromise quality. While competitive pricing is important, the value proposition of purchasing a machine extends beyond the initial costs. The right machine should promise longevity, reduced maintenance costs, and enhanced productivity, ultimately providing a return on investment that justifies the expenditure. In conclusion, selecting a cable cutting machine manufacturer involves evaluating experience, expertise, authoritativeness, and trustworthiness. Buyers should research thoroughly, considering not just the machines themselves but the comprehensive package offered by the manufacturer, from customer support to sustainability practices. By doing so, businesses will not only secure machinery that effectively meets their needs but will also forge a partnership with a company that supports their success and growth in the long term.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy