I-LED Ultraviolet Irradiation Polyolefin Crosslinking Equipment

Incazelo Yomkhiqizo

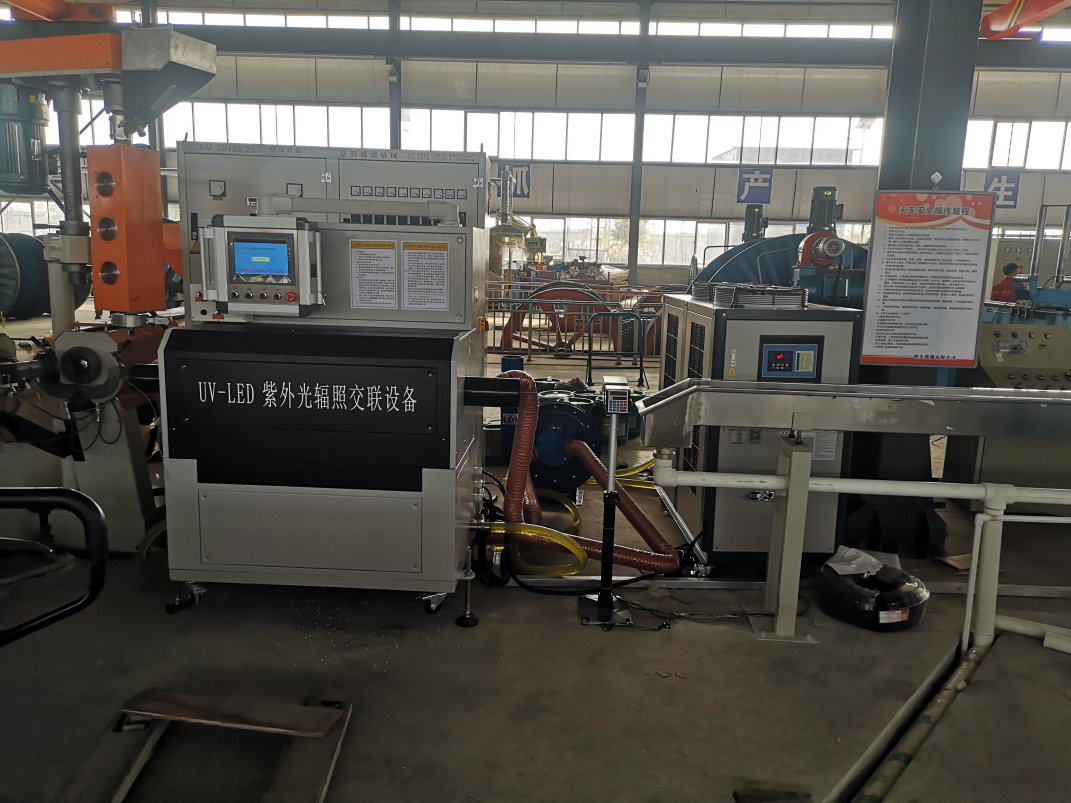

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

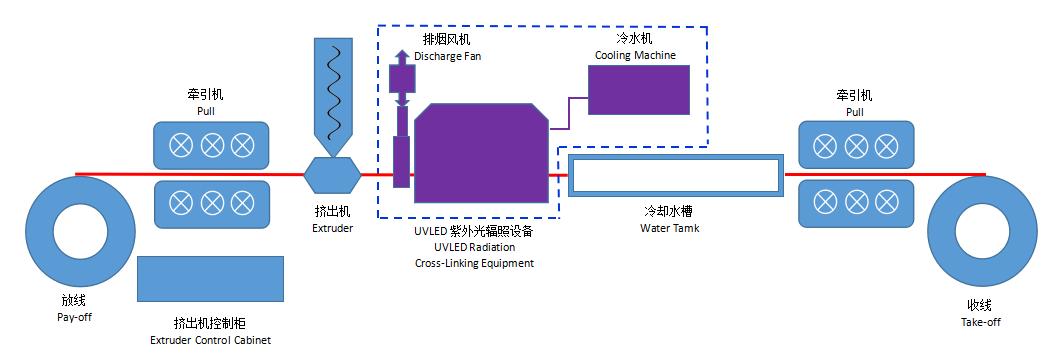

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Izici

Idivayisi ye-Ultraviolet LED ingumthombo wemisebe ye-ultraviolet ethuthuke kakhulu emhlabeni, enamandla amakhulu kakhulu (cishe ama-30%), ukukhetha okuphezulu okusebenzayo kwe-wavelength (umkhawulokudonsa wamandla ayingxenye ye-wavelength 5nm), impilo yesevisi ephezulu kakhulu (amahora angu-30,000), ukushisa okuphansi kwe-infrared isizukulwane, asikho isizukulwane se-ozone, esilungele kakhulu ukuphulukiswa okuxhumanisa ukuphambana kwe-polyolefin exhumene nesiphambano nezinye izinto.

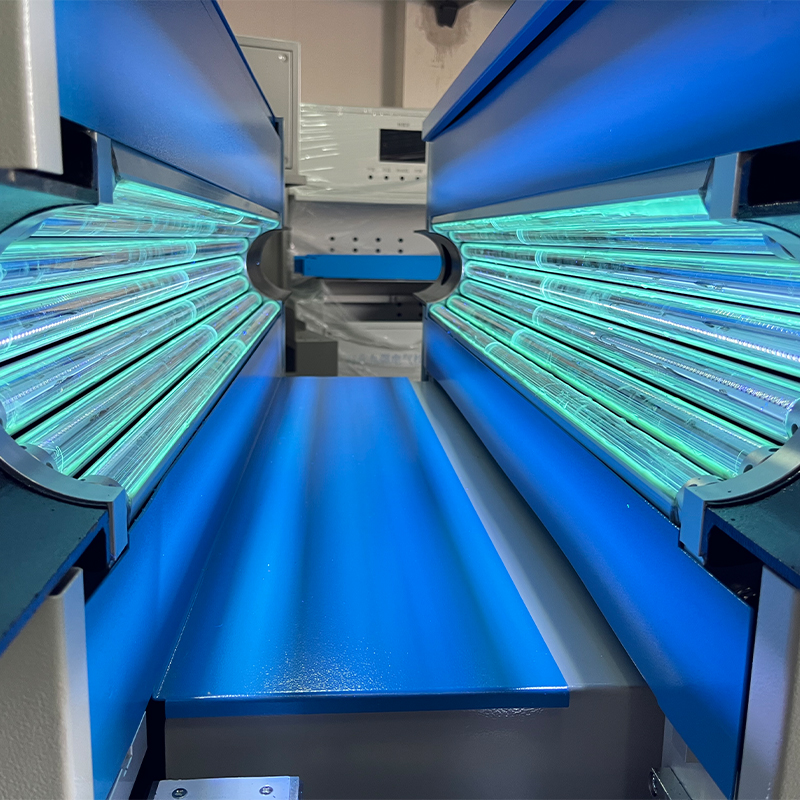

Umthombo we-UV LED usebenzisa isakhiwo selensi enelungelo lobunikazi ukuze ukhanyise ubuso bekhebula ngokulinganayo nangokulinganayo. Idizayini ye-substrate yenziwa ngenhlanganisela ye-Fluent software simulation fluid kanye nokuhlolwa kwezinga lokushisa kwe-junction ye-LED, futhi ibhodi lesifunda le-LED liklanywe ngenhlanganisela ye-aluminium nitride ceramic nesisekelo sethusi esisebenza kangcono ngokukhipha ukushisa, futhi inokukhipha ukushisa okuphumelelayo. uhlelo.

Umthombo we-UV LED usebenzisa umthombo wamandla wenethiwekhi osabalalisiwe ukushayela i-UV LED. Amandla kagesi okushayela ahlanganiswe ohlelweni lwe-vacuum potting ukuqinisekisa ukwethembeka kokunikezwa kwamandla. Ngesikhathi esifanayo, ukwakheka kwamandla okushayela kuthatha isakhiwo esincane futhi eside, futhi umthombo wokukhanya we-LED wohlobo olude usebenzisa imodi yokufaka i-back-to-back yesekethe ye-LED ukuze unciphise ubude bentambo. Bona ukuthi umthombo wokukhanya uvuliwe, uvaliwe, futhi ufiphalisa imisebenzi.

Imishini yokuxhumanisa i-UV LED irradiation polyolefin cross-linking yamukela isakhiwo somhubhe oyisiyingi, futhi ifakwe umthombo wokukhanya we-ultraviolet LED ukwenza umhubhe wokukhanyisa isifunda esimaphakathi, futhi amandla edivayisi angasethwa ngaphandle kwesinyathelo ebangeni le-10. ku-100%.

Uma kuqhathaniswa nemishini yokuxhumanisa isibani se-mercury yendabuko yohlobo lwe-irradiation (i-UVI/UVII eqhutshwa yi-transformer yendabuko kanye ne-UVE-I eqhutshwa ngamandla kagesi), ukuxhumanisa i-electron accelerator cross-linking, kanye ne-silane cross-linking, inalezi zinzuzo ezilandelayo:

1 Ukusetshenziswa Okuphansi Amandla

Amandla afakiwe e-UV LED irradiation polyolefin cross-linking alingana ne-1/4 yezinto zokuqala zokushisisa i-ultraviolet, i-1/30 ye-electron accelerator, amanzi noma umhwamuko wamanzi udinga ukufudumeza isikhathi eside, futhi ukusetshenziswa kwamandla okushisa kwamanzi kukhulu kakhulu. phezulu.

2 Isikhathi esifushane

I-cross-linking isebenzisa indlela yokuxhumanisa i-inthanethi ye-extrusion cross-linking ukuze kuncishiswe inqubo elandelayo yokuhlanganisa ukuxhumanisa, uma kuqhathaniswa nesikhathi esidingekayo sokuxhumanisa i-silene ebilisiwe noma esizwa ngesitimu kanye nokucutshungulwa kwe-electron beam irradiation, ukonga isikhathi sokukhiqiza izintambo. , ikakhulukazi izimo eziphuthumayo Ukuqedwa komsebenzi, izinzuzo zibalulekile.

3 Izindleko Eziphansi

Uma kuqhathaniswa nokuxhumanisa amanzi afudumele nokucutshungulwa kokusebenza kwemisebe ye-electron, intengo yekhebula lomsebe we-ultraviolet iphansi, futhi izinqubo eziningi eziyinkimbinkimbi ziyehliswa enqubweni yokukhiqiza, njengezindleko zokuthutha zezintambo eziqedwe kancane kanye nezindleko zomqhubi ezihambisanayo.

4 Ayikho i-Ozone

Ukukhethwa kwe-wavelength ephezulu kakhulu, kukhipha kuphela amaza awusizo, akukho misebe ye-infrared, inani eliphansi le-calorific; inani eliphansi kakhulu lemisebe ebonakalayo, akukho ukungcoliswa kokukhanya; akukho misebe ye-ultraviolet yamaza amafushane, akukho monakalo emzimbeni womuntu, ukukhishwa kwe-ozone okuyi-zero. Asikho isidingo sokupholisa ukugeleza komoya kwefeni enamandla amakhulu, asikho isidingo sepayipi elikhipha ukushisa eliyinkimbinkimbi ikakhulukazi ne-ozone-dicharging, sidinga kuphela ukuxhuma ipayipi lokukhipha umoya elinobubanzi obuncane kanye nesiphephetha-moya esingu-2kW ukuze singafaki intuthu ephansi yamangqamuzana ekhiqizwe ngesikhathi sokufakwa kwe-insulation. . Vimbela imiphumela ye-irradiation elula.

5 Usayizi Omncane, Kulula Ukuwufaka

Vele ungeze ibanga elingama-2m phakathi komugqa wokuqala wokukhiqiza isikhunta se-extruder kanye nethangi lamanzi afudumele, bese ubeka umshini wokukhipha imisebe endaweni engamamitha angu-2.5~3 ububanzi, noma encane. I-chiller ingabekwa endaweni.

6 Kulula Ukusebenza

Ukuvula nokuvala umhubhe othule, kulula ukuhlanza nokugqoka umkhondo, kulula ukusebenza, akukho nqubo eyinkimbinkimbi, ingaqedwa ngu-opharetha we-extruder.

7 Ukuphila Okude Nezindleko Zokulungisa Eziphansi

Ukuphila kwamadivayisi e-LED cishe amahora angu-30,000, futhi impilo yezinye izinto zikagesi neze-elekthronikhi ayikho ngaphansi kwempilo evamile yemikhiqizo kagesi neye-elekthronikhi, ngaphandle kokugcinwa njalo. Ukugcinwa okuvamile ukugcina i-lens optical ihlanzekile, izinto ezisetshenziswayo ziyi-industrial wipes kanye ne-soot cleaners, engenziwa ngu-opharetha. Izinto ezisetshenziswayo zendabuko zokuthela imisebe amalambu e-UV nezibonisi, ezidinga ukushintshwa ngesikhathi esifushane. Iyunithi ye-electronic ray irradiation nayo iyadingeka ukuze kugcinwe ithimba lokulungisa.

8 Okuhlaza

I-Ambient Air Quality Standard (GB3095-2012) ku-Industrial Hygiene Standard ibeka ukuthi izinga lokuphepha le-ozone ngu-0.15ppm. Imishini yokuxhumanisa i-UVLED UV ngeke ikhiqize i-ozone, kuyilapho izibani zesibani ze-mercury zendabuko zizokhiqiza inani elikhulu le-ozone. I-ozone igesi eyingozi.

1) Uhlu olubanzi lwezinhlelo zokusebenza

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Izindleko eziphansi

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Kulula ukufaka

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) Ukuthembeka okuphezulu

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Ukuqhathaniswa kwezinzuzo zokuxhumanisa okusha kwe-LED irradiation cross-linking ne-silane cross-linking:

|

Ukukhanya kwe-ultraviolet ukukhanya imishini |

Silane crosslinking imishini |

Ukonga izindleko |

|

|

Izindleko zezinto |

I-600 kg yemfucuza ngama-extruder angama-90 ngonyaka |

amathani ayi-12 emfucuza ngama-extruder angama-90 ngonyaka |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Amandla e-Extruder |

I-viscosity yezinto ezibonakalayo incane, ukusetshenziswa kwamandla kuncane, futhi ukukhishwa kwe-90 extruder cishe ku-30KW kuphela ngesivinini esigcwele. |

I-viscosity ephezulu yezinto, ukusetshenziswa kwamandla aphezulu, i-90 KW isivinini esigcwele esidingekayo |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Isikweletu sikagesi wokwenziwa |

Asikho isidingo sokuhlanza i-extruder |

Hlanza i-extruder isigamu sehora nsuku zonke |

Yonga u-3400 USD ngonyaka |

|

Izindleko zokuxhumanisa |

Uma sithatha ama-square metres angama-35 njengesibonelo, izindleko zikagesi zingama-80KW ngamamitha angama-30,000. |

Uma sithatha ama-square metres angama-35 njengesibonelo, kuthatha amahora ama-4 kumamitha angama-30,000 wokuxhumanisa umusi, futhi kudinga u-200KW kagesi. |

Save about 7000 USD in electricity every year |

|

Ukukhiqiza |

Ngesikhathi esifanayo i-cross-link ne-extruder, i-extrusion insulation ifakwe ngokuqondile ngaphandle kokucubungula okwesibili |

Ibilisiwe noma ifakwe ngesitimu okungenani amahora angu-4 (idinga indawo ekhethekile, ijeneretha yesitimu) |

Save 8400 USD per year |

|

Ikhwalithi yomkhiqizo |

Ukushisa kuncipha ngaphansi kuka-4%, akukho gel yangaphambili, indawo ebushelelezi |

Ukuncipha kokushisa okunamandla, ukwahlukanisa okuncane okuphambanayo kuvame ukuba nendawo engasheleli kanye nejeli. |

|

|

Ukutshalwa kwezimali kwemishini |

Maphakathi |

Phansi (igumbi lomusi noma ichibi elifudumele) |

|

|

Ukusetshenziswa kwamandla |

Phansi (idinga kuphela i-10 KW) |

Phezulu (idinga ukushisisa isikhathi eside) |

|

|

Izindleko zokukhiqiza |

Phansi |

Phezulu |

|

|

Umjikelezo wokukhiqiza |

Okufushane (okuxhumanisa ku-inthanethi) |

Yinde (idinga ukucutshungulwa kwesibili) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Ukuqhathaniswa kwezinzuzo zokukhanya okusha kwe-LED nokuxhumeka ku-inthanethi nesibani esidala se-mercury esinengcindezi ephezulu:

|

Umshini wokukhanyisa we-ultraviolet we-LED |

Umshini omdala we-mercury lamp irradiation machine |

|

|

Ukusetshenziswa kwamandla |

Isilinganiso esingaphansi kuka-15 kW ngehora |

80KW ngehora |

|

Izindleko zesondlo |

Phansi |

Phezulu |

|

Isivinini sokukhiqiza |

Phezulu |

Phansi |

|

Impilo yesibani |

30000 amahora |

Amahora angu-400 |

|

Izinto ezisetshenziswayo |

Cha |

Isibani, i-reflector, i-capacitor |

|

Ukukhiqiza |

I-extruder ayigcini ngesivinini esiphezulu futhi ingakhiqizwa ngokukhanyisa ukukhanya. |

Isivinini sokukhiqiza esinensayo, ukusebenza kahle okuphansi, ukuchithwa kwabasebenzi, kudingeka ukufudumala isigamu sehora kusengaphambili |

|

Indawo yokusebenza nendawo yaphansi |

Ukusebenza okulula, izinyathelo ezincane, akukho ukulinda |

Ukusebenza okuyinkimbinkimbi nendawo enkulu yaphansi |

|

Umshini omusha wokukhipha imisebe we-LED wonga izindleko zikagesi ezingu-34,000 USD. Izindleko zokusebenza ezingu-17,000 USD kanye nezinto ezisetshenziswayo ezingu-8,400 USD ngonyaka kunomshini omdala wokushiswa kwelambu le-mercury high-pressure high. |

||

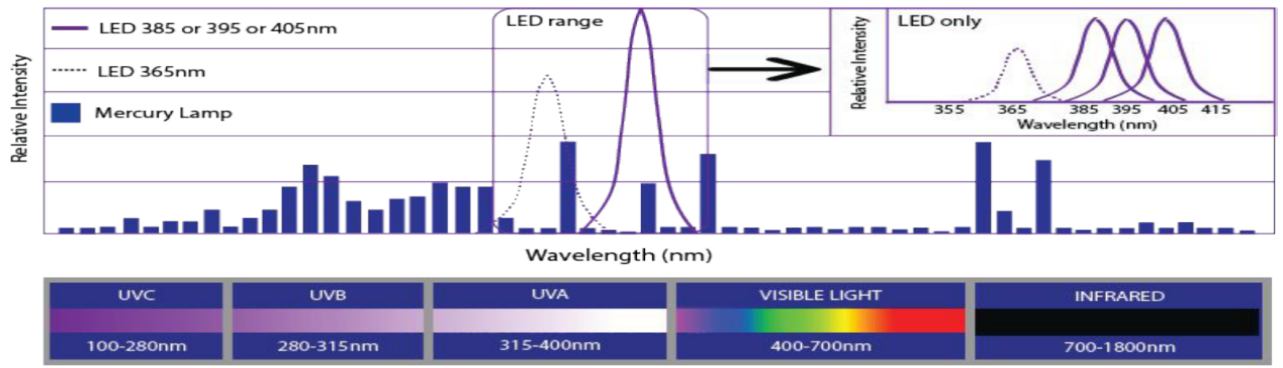

I-LED ne-mercury lamp spectral umehluko

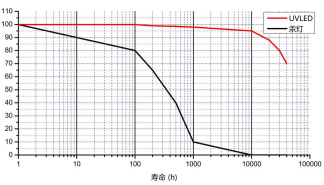

I-LED ne-mercury isibani sokuqhathanisa ukuphila

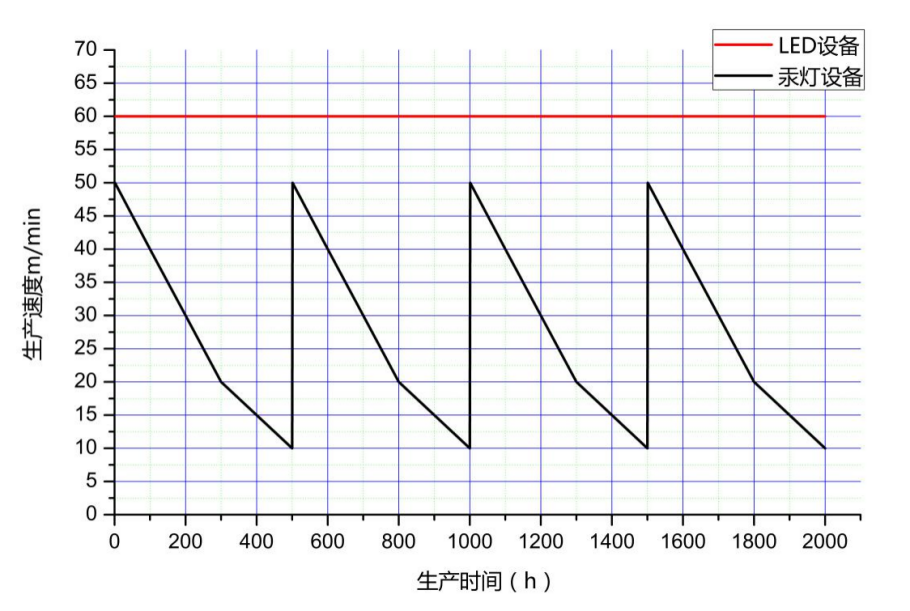

Ukuqhathaniswa kwejika lejubane lokukhiqiza phakathi kwemishini ye-mercury lamp irradiation kanye nemishini yokukhanyisela i-LED

Amapharamitha wokusebenza kwesisetshenziswa se-UV-LED Iradiation Crosslinking:

- 1. Amandla: isistimu yezintambo ezinhlanu zezigaba ezintathu (380V + N + umhlabathi)

- 2. Isamba samandla omshini afakiwe: 20kW

- 3. Ububanzi obuhle kakhulu bendawo yokukhipha imisebe: 30mm

4. Ubude bokukhipha imisebe obusebenzayo: 1m

- 5. Ubuhlalu besibani busebenzisa umthombo wokukhanya ongenisiwe ophezulu emhlabeni, i-lens isebenzisa i-quartz engenisiwe, ukuze ibe nokulahlekelwa kwamandla aphansi, isethi yesibani isebenzisa ubuchwepheshe bokupholisa uketshezi, ukuze umthombo wokukhanya we-LED ube nokuphila kwesevisi ende.

- 6. Ukunikezwa kwamandla kusebenzisa ugesi we-Taiwan Mingwei ongangeni manzi, ovikelwe ubuchwepheshe be-vacuum potting, ngokugcwala ngokweqile, isifunda esifushane, phezu kwamanje, phezu kwe-voltage kanye nokuvikelwa okungaphezulu kwezinga lokushisa.

7. Okukhipha amandla okukhanya kungalungiswa ngokungenasisekelo kusuka ku-10% -100%, ngokusho kwezidingo zekhasimende ukulungisa noma yimaphi amandla.

- 7. Impilo yomthombo wokukhanya: amahora angu-30,000 (ahlinzekwe umkhiqizi) Amandla okukhanya okukhiphayo ancishiswa abe ngu-70% (ukusebenza kahle kwehlela ku-70%). Isikhathi sokusebenzisa amahora angu-30,000, futhi isikhathi sokubala iminyaka engu-6 ~ 10.

9. Usayizi webhokisi lokukhanya: 1660mm*960mm*1730mm (ubude x ububanzi x ukuphakama)

Izici zesakhiwo sezisetshenziswa:

- 1. Ukuvula nokuvala umhubhe buthule, kulula ukuwusebenzisa nokuhlanza;

- 2. Ukusebenzisa isixhumi esibonakalayo somshini womuntu wokuthinta, idatha yokuqapha, nezilungiselelo zamandla enkinobho yokusebenza konke kuqediwe kusixhumi esibonakalayo sesikrini esithintwayo;

- 3. Umsebenzi wokulawula isikrini esithintwayo kanye nenkinobho ziqala ukuhlalisana ngokuhlukana;

- 4. Indlela yokupholisa ipholiswa yi-chiller, futhi i-circulating medium yenziwe nge-antifreeze ekhethekile yezimoto;

- 5. Indlela yokukhipha intuthu yangaphandle, ekhishwa ngomgudu womoya ongaphandle

Isakhiwo sezisetshenziswa

Isivinini sokukhiqiza se-cross-linked polyethylene irradiated material

|

Indawo 1

|

Indawo yesi-2

|

Indawo yesi-3

|

Indawo yesi-4

|

Zone 5

|

Ikhanda lomshini |

||

|

135℃ |

150 ℃ |

160 ℃ |

175℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

Ukuqina kwe-insulation nominal (mm)

|

Isivinini sokukhiqiza esingokwemvelo(m/min)

|

Isandiso sokushisa (%)

|

Ukuguqulwa okuhlala njalo |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Isivinini sokukhiqiza impahla ye-halogen engenawo umusi ophansi

|

Indawo 1

|

Indawo yesi-2

|

Indawo yesi-3

|

Indawo yesi-4

|

Zone 5

|

Ikhanda lomshini |

||

|

135℃ |

150 ℃ |

160 ℃ |

175℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

Ukuqina kwe-insulation nominal (mm)

|

Isivinini sokukhiqiza esingokwemvelo(m/min)

|

Isandiso sokushisa (%)

|

Ukuguqulwa okuhlala njalo |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Amazwana: Ngenxa yokuthi imishini ye-extrusion kanye nenqubo yokukhiqiza kanye nezinto zekhebula zamabhizinisi ahlukene zihlukile, isivinini se-extrusion sizohluka. I-90 extruder ayinqunyelwe.

Ukufakwa esizeni komshini wokuxhumanisa i-LED ultraviolet irradiation cross-linking