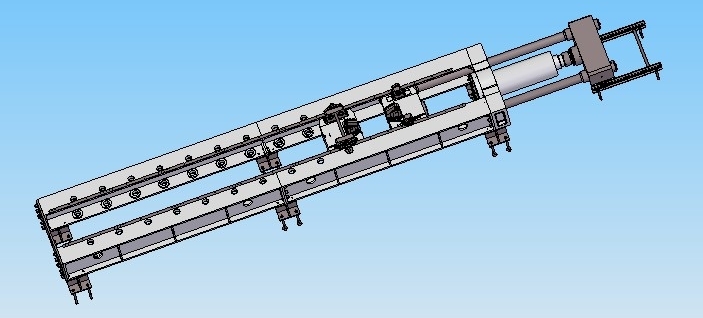

I-TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Incazelo Yomkhiqizo

I-TXWL-600 i-electro-hydraulic servo evundlile yokuhlola umshini wokuhlola i-tensile isebenzisa uhlaka lohlaka oluvundlile, isilinda sepiston esisebenza kabili esinamandla okuhlola, futhi uhlelo lokulawula lwekhompyutha lubona ukulawula okuzenzakalelayo kwenqubo yokuhlola ngokulawula i-servo valve nezinye izingxenye, ukuhlolwa. idatha iqoqwa ngokunembile inzwa yokulayisha futhi idluliselwe kukhompuyutha, isistimu ihlaziya ngokuzenzakalelayo, icubungule futhi igcine imiphumela yokuhlola, futhi iphrinta ingaphrinta ngokuqondile umbiko wokuhlola odingekayo. Lo mshini usetshenziselwa kakhulu ukuhlola okuqinile kwentambo yensimbi, ukukhiqizwa kwesimanje kocwaningo lwesayensi nokufundisa kanye nezinye izimboni ukuhlangabezana nezidingo zemishini yokuhlola efanele.

Incazelo Yomshini

1.Isistimu yokusingatha

Ingxenye yomshini oyinhloko yakhiwe ngokuyinhloko ifreyimu yomshini omkhulu, isihlalo sesilinda samafutha, isilinda samafutha, ugongolo olunyakazayo, isihlalo sangaphambili nangemuva se-chuck kanye nenzwa yomthwalo. Ingenza ukuhlolwa kwe-tensile ngomthwalo omkhulu wama-600kN kusampula.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Indawo yokuhlola ifakwe isembozo sokuzivikela, esingavikela ngempumelelo ukuphepha kwabasebenzi abahlolayo.

2.Isistimu yomthombo wamafutha

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Isigaba sikagesi

Ukulawulwa kukagesi kuhlelwe endaweni yokusebenza yokuhlola, futhi kunephaneli yokusebenza eklanywe ngokukhethekile ukwenza zonke izinhlobo zokusebenza zicace lapho uthi nhla. Izingxenye zikagesi ziwumkhiqizo odumile wamazwe ngamazwe, nokusebenza okuzinzile kanye nekhwalithi ethembekile.

Uhlelo Lwesoftware:

(1) Ngokusekelwe ku-Windows XP yesikhulumi esinemisebenzi ehlelekayo, ukulawula amandla okuhlola alinganayo, ukulawula ukufuduka okulinganayo, ukubamba amandla okuhlola, ukubamba ukususwa nezinye izindlela zokuhlola kungahlanganiswa ngokuthanda kwakho ukuze kuhlangatshezwane nezidingo zezindlela ezihlukahlukene zokuhlola. ngokwezinga eliphezulu, kanye nokubona ukuboniswa kwedatha okuhlukahlukene, ukudweba ijika, ukucubungula idatha, ukugcinwa kanye nemisebenzi yokuphrinta edingekayo ekuhlolweni.

(2) Thumela isignali yokulawula ku-valve ye-servo ngekhompyutha ukuze ulawule ukuvuleka nokuqondisa kwe-valve ye-servo, ngaleyo ndlela ulawule ukugeleza ku-cylinder, futhi uqaphele ukulawulwa kwamandla okuhlola alinganayo, ukugudluka okulinganayo, njll. .

(3) Ifakwe izihibe ezimbili ezivaliwe zokulawula amandla okuhlola kanye nokufuduka.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) I-interface eyinhloko inayo yonke imisebenzi yokusebenza kwansuku zonke kokuhlolwa, njengokufakwa kolwazi lwesampula, ukukhetha isampula, ukudweba ijika, ukubonisa idatha, ukucubungula idatha, ukuhlaziywa kwedatha, ukusebenza kokuhlola, njll. Ukusebenza kokuhlola kulula futhi ngokushesha.

(6) Idatha ingakhishelwa iphrinta ukuze iphrinte umbiko wokuhlola.

(7) Ukuphathwa kokuhlelwa kwesistimu, imingcele yesistimu yonke ivulekele abasebenzisi abangochwepheshe, iqinisekisa ukuguquguquka nokuthembeka kwesistimu.

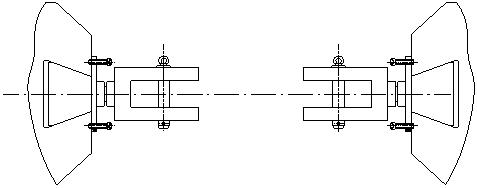

4.Izesekeli zokuhlola

Ifakwe izesekeli zokuhlola izintambo zocingo (bheka ngezansi) nezinye izesekeli kukhiqizwa ngokwezinga elihlinzekwe umsebenzisi noma izidingo zokushuba kwesampula.

5.Amadivayisi Okuvikela Ukuphepha

(1) Ukuvikela ukulayisha ngokweqile lapho amandla okuhlola edlula u-2% kuya ku-5% wamandla okuhlola amaningi noma inani elibekiwe.

(2) Ukuvikelwa kwe-stroke lapho ipiston ithuthela endaweni elinganiselwe.

(3) Ngezinga lokushisa likawoyela, izinga loketshezi kanye nokuvikelwa kokumelana nowoyela kanye nemishini yezinkomba.

(4) Isikhala sokuhlola sinesembozo sokuvikela ukuvimbela isampula ukuthi ingaphuki futhi ingaphumi.

(5) Uma kuvela isimo esiphuthumayo, cindezela inkinobho yokumisa izimo eziphuthumayo ekhabetheni lokulawula ngqo

Ipharamitha yezobuchwepheshe

1.Amandla okuhlola aphezulu: 600kN

2.Ibanga lokulinganisa amandla okuhlola: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Isikhala sokuhlola esiqinile (ngaphandle kwe-piston stroke): 20mm ~ 12000mm

5.Piston stroke: 1000mm

6.Isivinini esikhulu sokusebenza se-piston: 100 mm/min

7.Ukunemba kwe-extensometer ye-Deformation: 0.01mm

8.Ubukhulu bomshini omkhulu(mm): 16000(L) x 1300(W) x 1000(H) (ngaphandle kwekhava yokuvikela)