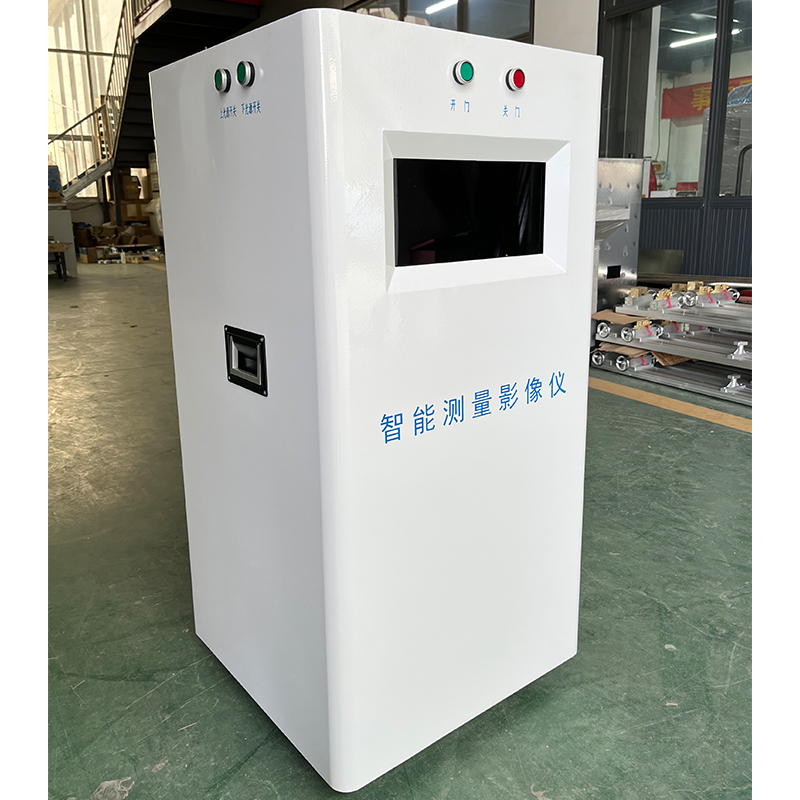

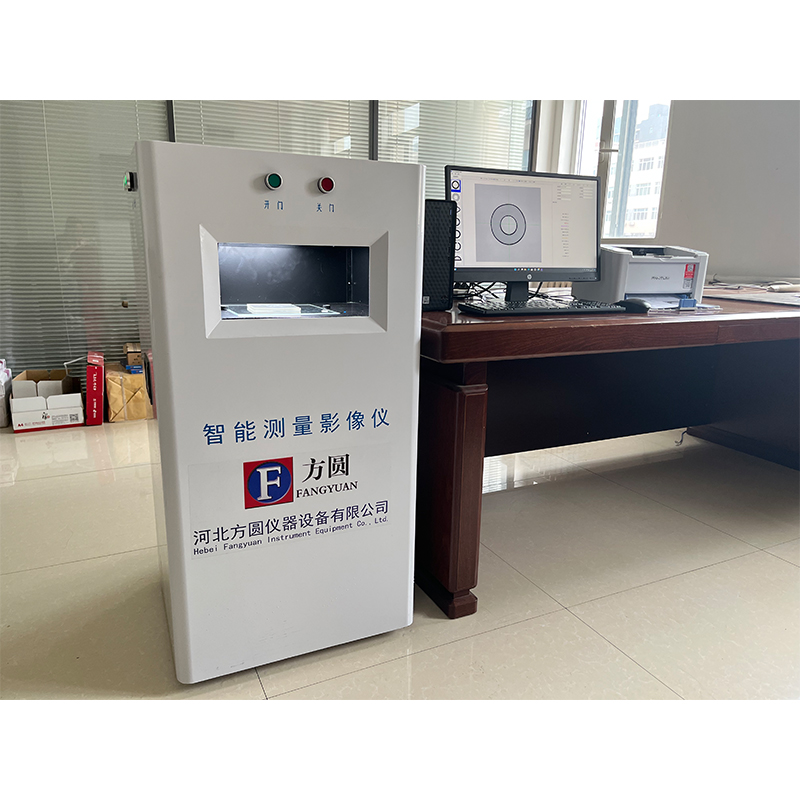

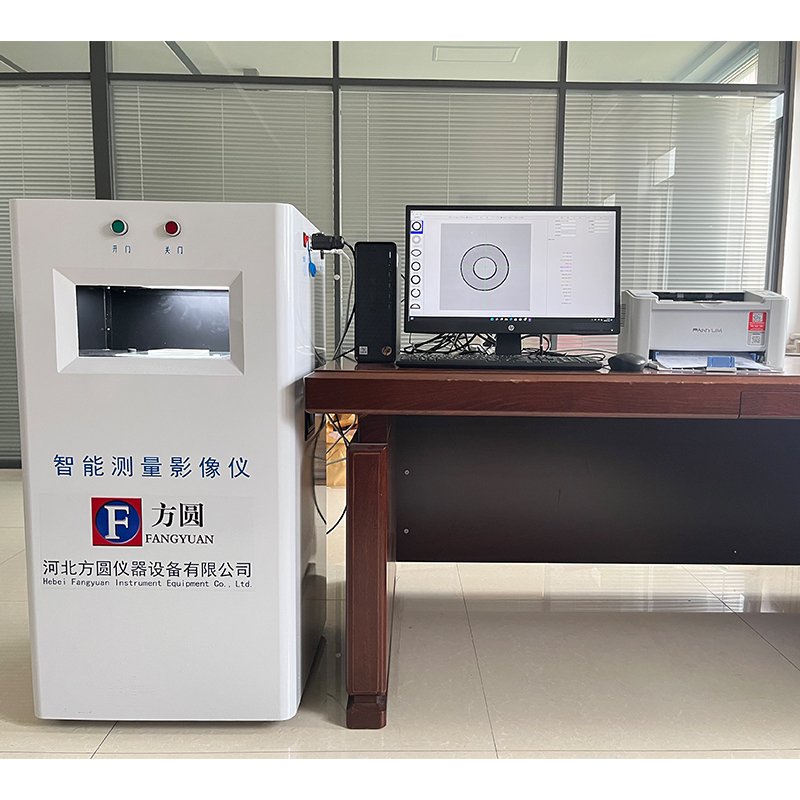

FYTY Series Intelligent Measuring Imager

Product Description

Meet the standard: IEC60811,TB2809-2017,GB/T2951

The intelligent measuring imager is an independently developed measuring system that uses visual inspection methods to measure the structure data of wires and cables. The product is designed and manufactured in accordance with the measurement requirements of the thickness and dimensions of the IEC 60811-1-1(2001)/GB/T2951.11-2008/TB2809-2017 (the implementation standard for locomotive contact wires)standards.

Through the combination of machine vision and computer image processing technology, this product can quickly and accurately detect the thickness, outer diameter, eccentricity, concentricity, ellipticity and other measurements of insulation and sheath of many kinds of wires and cables specified in the standard, and also measure the cross-sectional area value of each layer and conductor. The measurement accuracy of the instrument is far better than the accuracy required by the standard.

Functions and Features

Using computer vision technology, inspection is rapid and timely, far exceeding the measurement speed of manual projectors and reading microscopes. Automatic inspection of the structural parameters of the cable according to the inspection shape selected by the user enables more accurate inspection accuracy than manual measurement and the measurement specifications required by IEC 60811-1-1 (2001). Use LED parallel light sources to improve lighting uniformity and life to ensure continuous and stable light. Fast measurement data can quickly guide product production, ensure product quality, and can reduce the cost of cable production materials, reduce the error rate of human measurement and improve measuring efficiency.

Keep track of the latest IEC wire and cable standards and test methods in time. Free program upgrades are provided to users, and the professionally designed body structure ensures reasonable and reliable measurements. Using high performance industrial digital cameras with 10 megapixel (1-80mm) and 20 megapixel (80-140mm) CMOS sensors four different groups of cameras can detect various wire and cable insulation and sheath size data from 1mm diameter to 140mm diameter.

Configuration

High-precision CCD and lens are used as image acquisition devices to perform imaging and sampling to achieve accurate and stable sample testing and improve testing efficiency.

Non-contact measurement, independently and objectively measure the tested object, effectively avoiding the uncertainty of manual measurement.

|

Item |

Operating system of intelligent measuring imager |

|||

|

Test parameters |

The thickness, outer diameter and elongation data of the insulation and sheath materials of cables and optical cables |

|||

|

Sample type |

Insulation and sheath materials for cables and optical cables (elastomers, polyvinyl chloride, polyethylene, polypropylene, etc.) |

|||

|

Measuring range |

1-10mm |

10-30mm |

30-80mm |

80-140mm |

|

Camera |

No.1 |

No.2 |

No.3 |

No.4 |

|

Sensor type |

CMOS progressive scan |

CMOS progressive scan |

CMOS progressive scan |

CMOS progressive scan |

|

Lens pixel |

10 million |

10 million |

10 million |

20 million |

|

Image resolution |

2592*2600 |

2592*2600 |

2704*2700 |

3488*3500 |

|

Display resolution |

0.001mm |

|||

|

Measurement repeatability (mm) |

≤0.002 |

≤0.005 |

≤0.01 |

≤0.03 |

|

Measurement accuracy (μm) |

4+L/100 |

8+L/100 |

20+L/100 |

40+L/100 |

|

Lens switching |

Freely switch lens |

|||

|

Test time |

≤10sec |

|||

|

Test procedure |

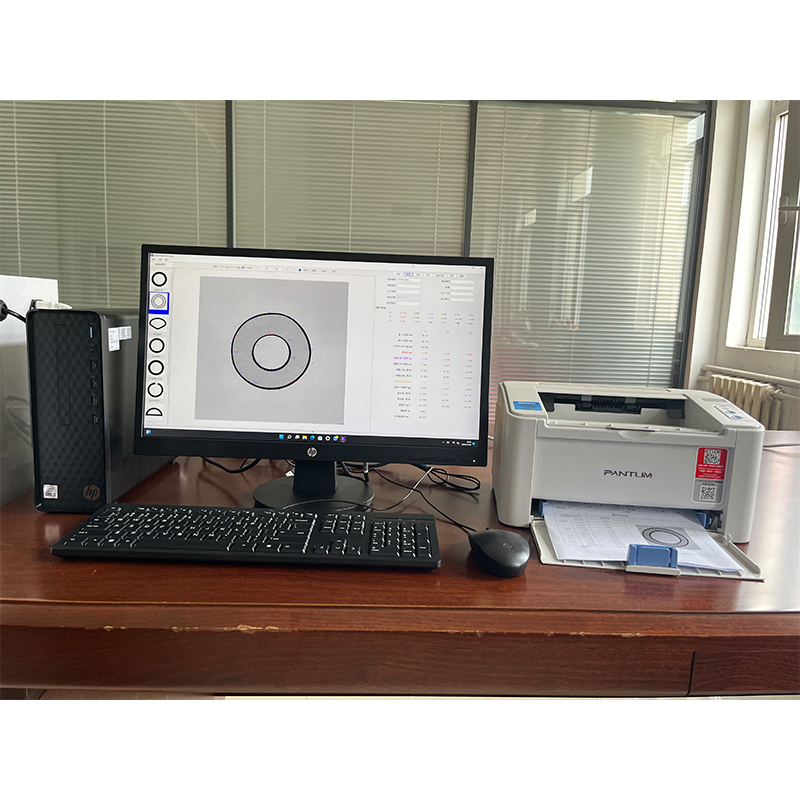

One click measurement, click the measurement button with the mouse, the software will be tested automatically, all parameters will be tested at one time, the test report will be issued automatically, and the data will be stored in the database automatically.

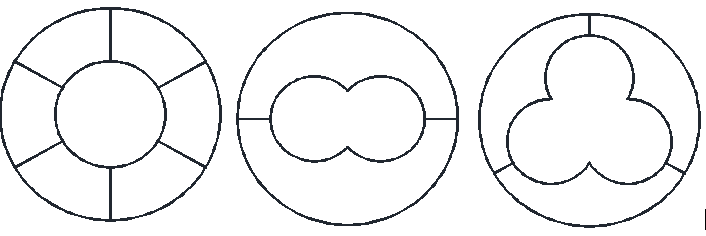

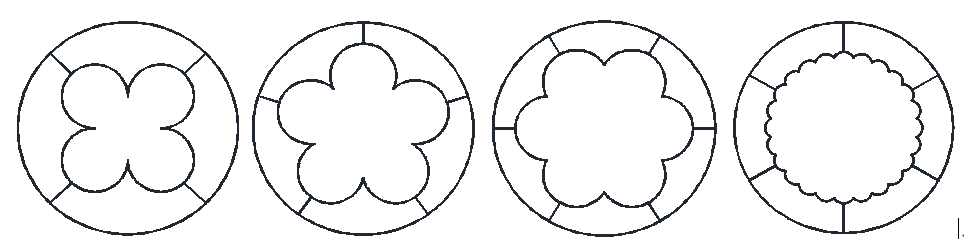

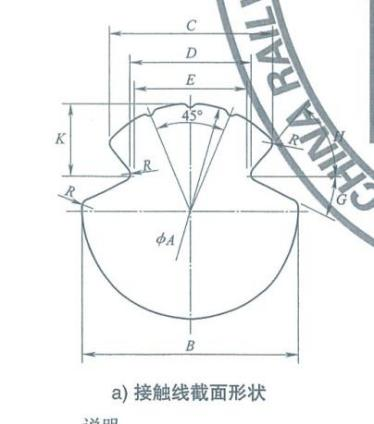

Testing software: 1. Testable cable insulation and sheath shape include IEC60811. Figure 1 to Figure 11. ①Insulation and sheath thickness measurement (round inner surface) ②Insulation thickness measurement (sector-shaped conductor) ③Insulation thickness measurement (stranded conductor) ④Insulation thickness measurement (irregular outer surface) ⑤Insulation thickness measurement (flat double core non sheathed flexible wire) ⑥Sheath thickness measurement (irregular circular inner surface) ⑦Sheath thickness measurement (non-circular inner surface) ⑧Sheath thickness measurement (irregular outer surface) ⑨Sheath thickness measurement (flat double core cord with sheath) ⑩Sheath thickness measurement (multi-core flat cable) TB2809-2017 (executive standard for locomotive contact wire) section size and angle measurement.

2.Support the test of three-layer coextrusion shape cable of medium and high voltage cable.

3.Insulation and sheath test items Maximum thickness, minimum thickness and average thickness. Maximum diameter, minimum diameter, average diameter, cross-sectional area. Eccentricity, concentricity, ovality (circular).

4.Conductor reference cross-sectional area

5.The measurement method independently designed based on 3C requirements: meet the requirements of 1.9.2 in GB/ t5023.2-2008: "take three sections of samples for each insulated wire core, measure the average value of 18 values (expressed in mm), calculate to two decimal places, and round off according to the following provisions (see standard terms for rounding off rules), and then take this value as the average value of insulation thickness." A unique 3C report can be generated, with qualification determination function.

6.Manual measurement function: even if you meet the section shape of wire and cable insulation thickness not listed in the standard, the manual measurement function is added in the software. Just click the position to be measured in the section view, that is, the point-to-point length will be displayed automatically. After the measurement, the minimum thickness and average thickness of these positions can be displayed automatically。 |

|||

|

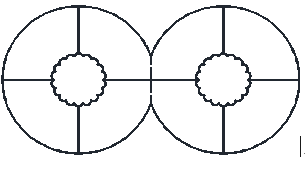

Calibration function |

A standard ring calibration board is provided, which can be used for instrument calibration |

|||

|

Long life light source |

High density LED parallel light source, monochromatic light, reduce scattering and highlight the contour of the measured object to the greatest extent. The unique 90 degree angle auxiliary cross light source design can measure opaque samples. |

|||

|

Light path system |

Fully sealed chassis, adopts vertical dust-proof optical path system to reduce optical refraction. |

|||

|

Measuring light chamber |

The all-black light room reduces diffuse reflection, eliminates stray light interference, and avoids false data errors. |

|||

Light Source Parameters

|

Item |

Type |

Color |

Illuminance |

|

Parallel backlight |

LED |

White |

9000-11000LUX |

|

2 cross auxiliary light sources |

LED |

White |

9000-11000LUX |

Computer

Processor Intel G6400, quad-core, 4.0GHz, 4G memory, 1TG hard drive, 21.5-inch display, operating system window10

Printer

Laser printer, A4 paper, black and white printing

Sample

Round pieces (7 types)

Regular ring Double-core round Three-core round

Four-core round Five-core round Six-core round Irregular ring

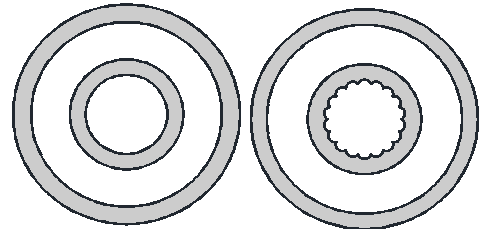

Three-layer ring (2 types)

Description: Internal smooth ring and internal burr ring

Smooth inner ring Internal burr ring

Telescope (1 type)

Sector (1 type)

Double core flat (1 type)

Irregular surface round (2 types)

Single-layer three-core irregular circles Single-layer irregular circles inside and outside

TB2809-2017 (Executive Standard for Locomotive Contact Wire) Sectional Dimensions and Angle Measurement

Measurement of insulation layer of opaque double-layer or triple-layer rubber sheathed high-voltage cable

Use Environmental Conditions

|

No. |

Item |

Unit |

Project unit required value |

||

|

1 |

Ambient temperature |

Maximum daily temperature |

℃ |

+40 |

|

|

Minimum daily temperature |

-10 |

||||

|

Maximum daily temperature difference |

℃ |

30 |

|||

|

2 |

Altitude |

M |

≤2000 |

||

|

3 |

Relative humidity |

Maximum daily relative humidity |

|

95 |

|

|

Maximum monthly average relative humidity |

90 |

||||

Machine configuration

|

Item |

Model |

Qty |

Unit |

|

|

Intelligent measuring imager |

FYTY-60 |

1 |

Set |

|

|

1 |

Machine |

|

1 |

Set |

|

2 |

Computer |

|

1 |

Set |

|

3 |

Laser printer |

|

1 |

Set |

|

4 |

Calibration board |

|

1 |

Set |

|

5 |

Pressed glass |

150*150 |

1 |

Piece |

|

6 |

USB data cable |

|

1 |

Piece |

|

7 |

Software |

|

1 |

Set |

|

8 |

Operating Instructions |

|

1 |

Set |