FYTY Series Kev Ntsuas Ntsuas Ntsuas Duab

Product Description

Ua tau raws li tus qauv: IEC60811, TB2809-2017, GB / T2951

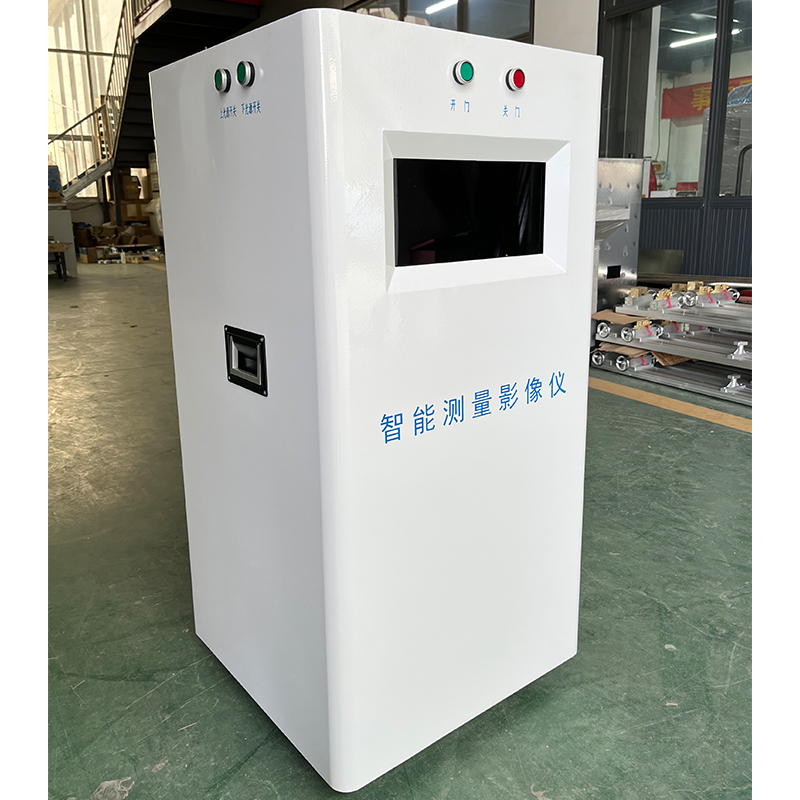

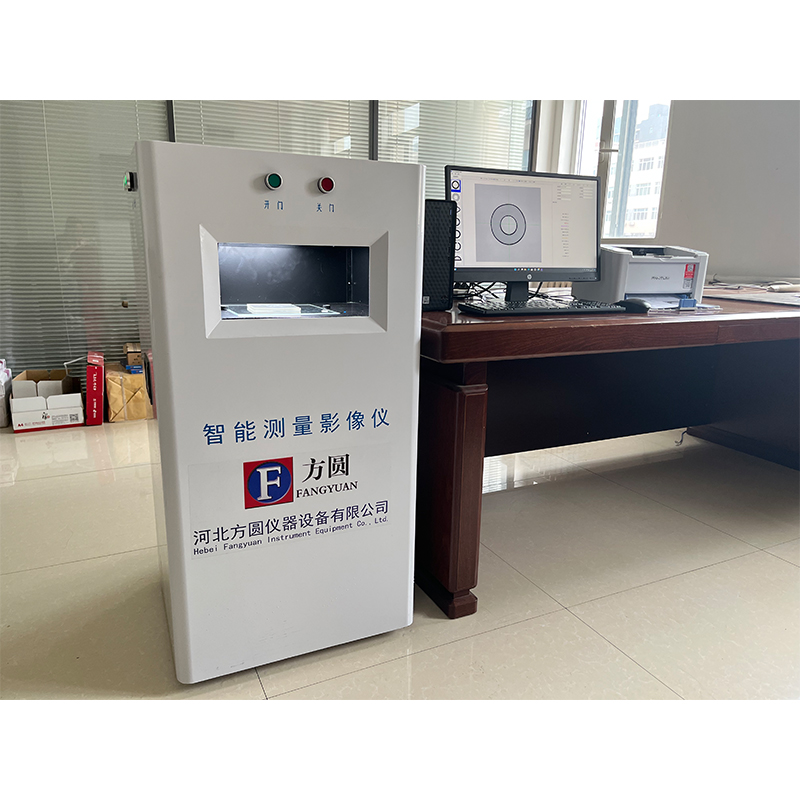

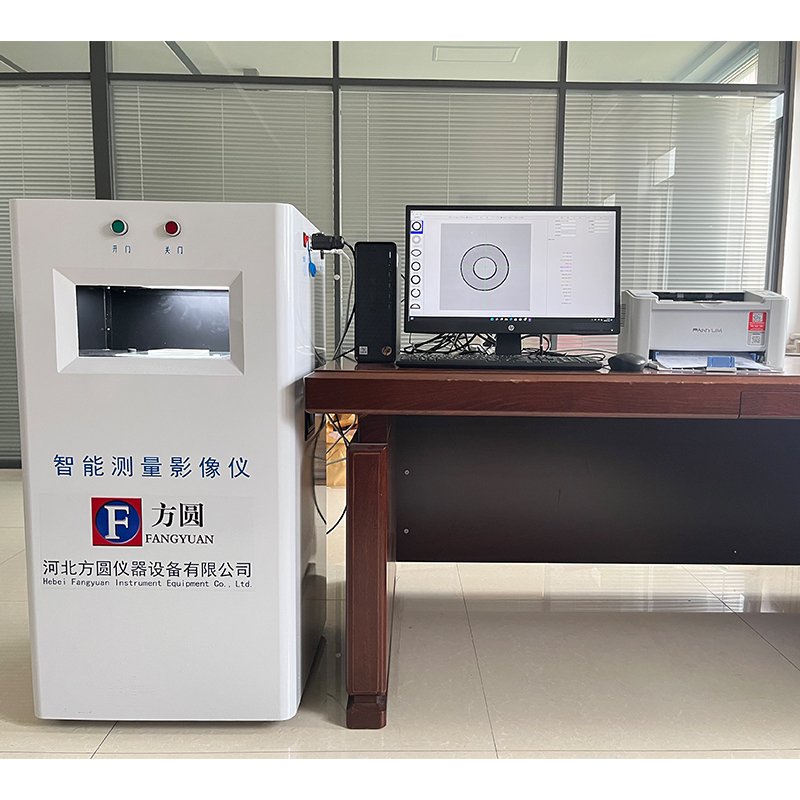

The intelligent measuring imager is an independently developed measuring system that uses visual inspection methods to measure the structure data of wires and cables. The product is designed and manufactured in accordance with the measurement requirements of the thickness and dimensions of the IEC 60811-1-1(2001)/GB/T2951.11-2008/TB2809-2017 (the implementation standard for locomotive contact wires)standards.

Los ntawm kev sib xyaw ua ke ntawm kev pom kev tshuab thiab tshuab computer duab, cov khoom no tuaj yeem tshawb xyuas qhov tuab, sab nraud, eccentricity, concentricity, ellipticity thiab lwm yam kev ntsuas ntawm rwb thaiv tsev thiab sheath ntawm ntau hom xov hlau thiab cables teev nyob rau hauv tus qauv, thiab kuj ntsuas tus nqi ntawm qhov chaw seem ntawm txhua txheej thiab tus neeg xyuas pib. Kev ntsuas qhov tseeb ntawm lub ntsuas ntsuas yog qhov zoo tshaj qhov tseeb ntawm tus qauv.

Muaj nuj nqi thiab nta

Using computer vision technology, inspection is rapid and timely, far exceeding the measurement speed of manual projectors and reading microscopes. Automatic inspection of the structural parameters of the cable according to the inspection shape selected by the user enables more accurate inspection accuracy than manual measurement and the measurement specifications required by IEC 60811-1-1 (2001). Use LED parallel light sources to improve lighting uniformity and life to ensure continuous and stable light. Fast measurement data can quickly guide product production, ensure product quality, and can reduce the cost of cable production materials, reduce the error rate of human measurement and improve measuring efficiency.

Ua raws li qhov tseeb IEC hlau thiab cable qauv thiab cov txheej txheem sim nyob rau lub sijhawm. Kev hloov kho dawb pub dawb yog muab rau cov neeg siv, thiab cov qauv tsim lub cev ua haujlwm ua kom muaj kev ntsuas tsim nyog thiab txhim khu kev qha. Siv cov koob yees duab digital digital nrog kev ua haujlwm siab nrog 10 megapixel (1-80mm) thiab 20 megapixel (80-140mm) CMOS sensors plaub pawg ntawm cov koob yees duab tuaj yeem ntes ntau yam hlau thiab cable rwb thaiv tsev thiab cov ntaub ntawv loj los ntawm 1mm txoj kab uas hla mus rau 140mm txoj kab uas hla.

Kev teeb tsa

High-precision CCD thiab lo ntsiab muag yog siv los ua cov duab nrhiav tau los ua cov duab thiab cov qauv kom ua tiav cov qauv kuaj kom raug thiab ruaj khov thiab txhim kho kev sim.

Kev ntsuas tsis sib cuag, nws tus kheej thiab lub hom phiaj ntsuas cov khoom ntsuas, ua tau zoo kom tsis txhob muaj qhov tsis paub meej ntawm phau ntawv ntsuas.

|

Yam khoom |

Kev khiav hauj lwm system ntawm ntse ntsuas imager |

|||

|

Ntsuas qhov ntsuas |

Cov ntaub ntawv thickness, txheej kab thiab elongation ntawm cov ntaub ntawv rwb thaiv tsev thiab sheath ntawm cables thiab optical cables |

|||

|

Hom qauv |

Rwb thaiv tsev thiab sheath ntaub ntawv rau cables thiab optical cables (elastomers, polyvinyl chloride, polyethylene, polypropylene, thiab lwm yam) |

|||

|

Kev ntsuas ntau |

1-10 hli |

10-30 hli |

30-80 hli |

80-140 hli |

|

Lub koob yees duab |

No.1 |

No.2 |

No.3 |

No.4 |

|

Sensor hom |

CMOS nce qib scan |

CMOS nce qib scan |

CMOS nce qib scan |

CMOS nce qib scan |

|

Lens pixel |

10 lab |

10 lab |

10 lab |

20 lab |

|

Duab daws teeb meem |

2592*2600 |

2592*2600 |

2704*2700 |

3488*3500 |

|

Zaub daws teeb meem |

0.001 hli |

|||

|

Kev ntsuas repeatability (mm) |

≤0.002 |

≤0.005 |

≤0.01 |

≤0.03 |

|

Measurement accuracy (μm) |

4 + L / 100 |

8 + L / 100 |

20 + L / 100 hli |

40 + L / 100 hli |

|

Lens hloov |

Dawb hloov lens |

|||

|

Lub sijhawm kuaj |

≤10sec |

|||

|

Cov txheej txheem kuaj |

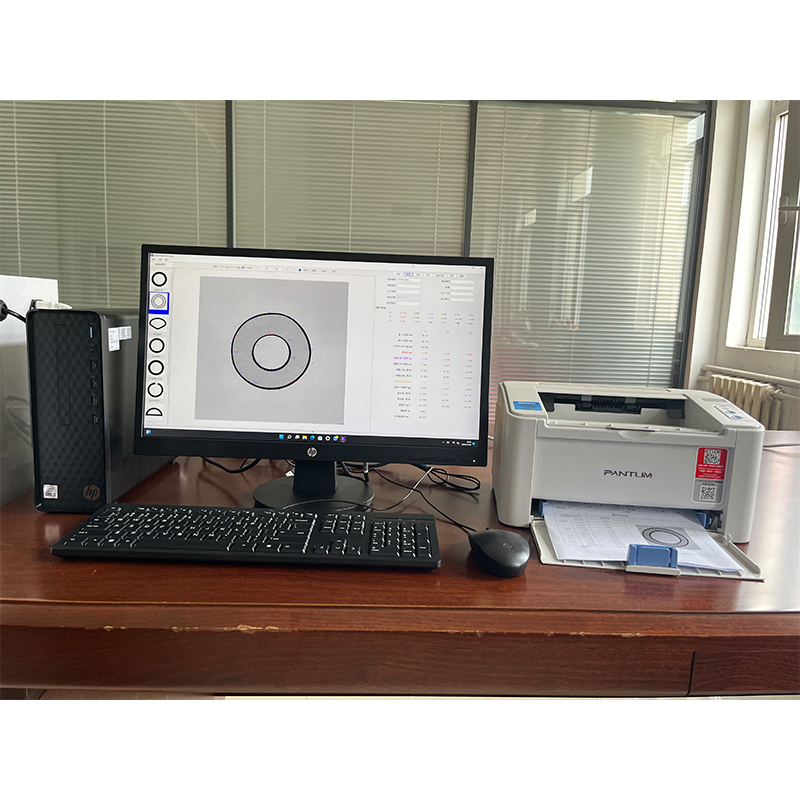

Ib nias ntsuas, nias lub ntsuas khawm nrog tus nas, lub software yuav raug kuaj cia li, tag nrho cov kev ntsuas yuav raug kuaj ib zaug, daim ntawv ntsuam xyuas yuav raug muab tso tawm, thiab cov ntaub ntawv yuav muab cia rau hauv lub database cia li.

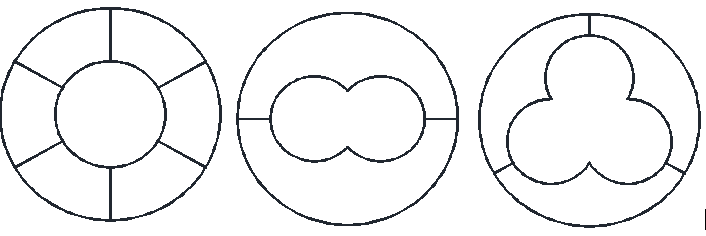

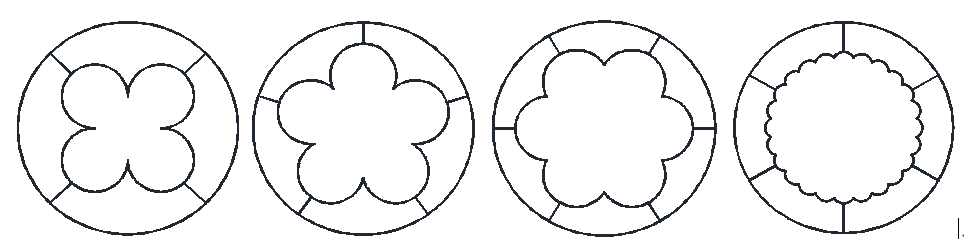

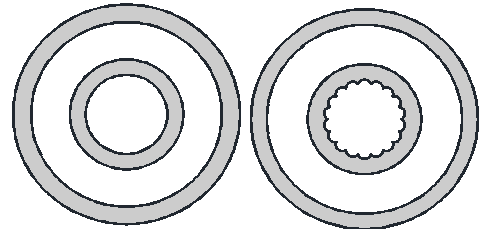

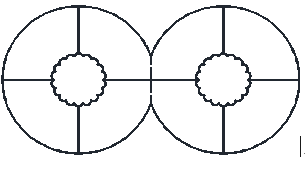

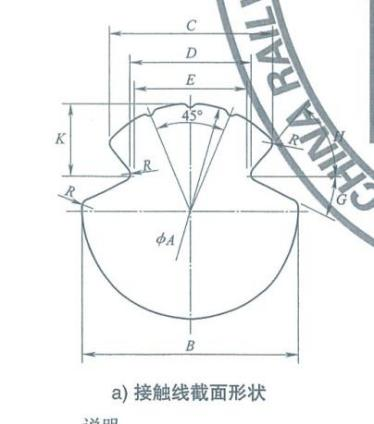

Test software: 1. Testable cable rwb thaiv tsev thiab sheath puab muaj xws li IEC60811. Daim duab 1 txog daim duab 11. ①Insulation thiab sheath thickness ntsuas (round puab nto) ②Insulation thickness ntsuas (sector-shaped conductor) ③ Rwb thaiv tsev thickness ntsuas (stranded conductor) ④ Insulation thickness ntsuas (tsis xwm yeem sab nrauv) ⑤ Rwb thaiv tsev thickness ntsuas (pas ob chav tub ntxhais tsis sheathed saj zawg zog hlau) ⑥ Sheath thickness ntsuas (tsis xwm yeem ncig sab hauv) ⑦ Sheath thickness ntsuas (tsis yog voj voog sab hauv) ⑧ Sheath thickness ntsuas (tsis xwm yeem sab nrauv) ⑨ Sheath thickness ntsuas (pav ca ob chav tub ntxhais qaum nrog sheath) ⑩ Sheath thickness ntsuas (multi-core ca cable) TB2809-2017 (tus qauv ua haujlwm rau locomotive hu xov tooj) ntu loj thiab lub kaum sab xis ntsuas.

2.Txhawb qhov kev sim ntawm peb-txheej coextrusion zoo cable ntawm nruab nrab thiab high voltage cable.

3.Insulation thiab sheath xeem cov khoom Maximum thickness, yam tsawg kawg nkaus thickness thiab nruab nrab thickness. Qhov siab tshaj plaws txoj kab uas hla, qhov tsawg kawg nkaus txoj kab uas hla, nruab nrab txoj kab uas hla, qhov chaw hla ntu. Eccentricity, concentricity, ovality (lub voj voog).

4.Conductor siv cross-sectional cheeb tsam

5.Txoj kev ntsuas nws tus kheej tsim raws li 3C cov kev cai: ua tau raws li qhov yuav tsum tau ua ntawm 1.9.2 hauv GB / t5023.2-2008: "koom peb ntu ntawm cov qauv rau txhua qhov insulated hlau core, ntsuas qhov nruab nrab ntawm 18 qhov tseem ceeb (qhia hauv mm), xam rau ob qhov chaw decimal, thiab tig tawm raws li cov kev cai hauv qab no (saib cov ntsiab lus rau kev sib sau cov cai), thiab tom qab ntawd coj tus nqi no raws li tus nqi nruab nrab ntawm rwb thaiv tsev thickness. Daim ntawv tshaj tawm 3C tshwj xeeb tuaj yeem tsim tau, nrog rau kev txiav txim siab muaj nuj nqi.

6.Manual measurement function: even if you meet the section shape of wire and cable insulation thickness not listed in the standard, the manual measurement function is added in the software. Just click the position to be measured in the section view, that is, the point-to-point length will be displayed automatically. After the measurement, the minimum thickness and average thickness of these positions can be displayed automatically。 |

|||

|

Calibration muaj nuj nqi |

Lub nplhaib txheem calibration board yog muab, uas tuaj yeem siv rau kev ntsuas ntsuas |

|||

|

Lub neej ntev lub teeb ci |

High density LED parallel teeb qhov chaw, lub teeb monochromatic, txo kev tawg thiab teeb pom kev zoo ntawm cov khoom ntsuas mus rau qhov loj tshaj plaws. Qhov tshwj xeeb 90 degree lub kaum sab xis auxiliary hla lub teeb tsim tuaj yeem ntsuas cov qauv opaque. |

|||

|

Lub teeb txoj kev system |

Tag nrho kaw chassis, txais yuav ntsug plua plav-pov thawj kho qhov muag txoj kev kom txo tau qhov muag pom kev. |

|||

|

Ntsuas lub teeb chamber |

Chav tsev tag nrho-dub lub teeb txo qhov kev xav tsis thoob, tshem tawm cov teeb pom kev tsis zoo, thiab zam cov ntaub ntawv tsis raug. |

|||

Lub teeb Source Parameters

|

Yam khoom |

Hom |

Xim |

Teeb pom kev zoo |

|

Parallel backlight |

LED |

Dawb |

9000-11000 LUX |

|

2 cross auxiliary light sources |

LED |

Dawb |

9000-11000 LUX |

Khoos phis tawj

Processor Intel G6400, quad-core, 4.0GHz, 4G nco, 1TG hard drive, 21.5-nti zaub, operating system window10

Lub tshuab luam ntawv

Laser tshuab luam ntawv, A4 ntawv, luam ntawv dub thiab dawb

Qauv

Round pieces (7 yam)

Regular ring Double-core round Three-core round

Four-core round Five-core round Six-core round Irregular ring

Peb-txheej nplhaib (2 hom)

Nqe lus piav qhia: Internal smooth nplhaib thiab internal burr nplhaib

Smooth inner ring Internal burr ring

Telescope (1 hom)

Sector (1 yam)

Ob chav tub ntxhais tiaj tiaj (1 hom)

Irregular nto puag ncig (2 hom)

Single-layer three-core irregular circles Single-layer irregular circles inside and outside

TB2809-2017 (Txoj Cai Ua Haujlwm rau Locomotive Contact Wire) Sectional Dimensions thiab Angle Measurement

Kev ntsuas ntawm rwb thaiv tsev txheej ntawm opaque ob-txheej los yog triple-txheej roj hmab sheathed high-voltage cable

Siv Environmental Conditions

|

Tsis muaj. |

Yam khoom |

Chav tsev |

Qhov project unit xav tau tus nqi |

||

|

1 |

Ambient kub |

Qhov kub siab tshaj plaws txhua hnub |

℃ |

+40 |

|

|

Yam tsawg kawg txhua hnub kub |

-10 |

||||

|

Qhov kub siab tshaj plaws txhua hnub sib txawv |

℃ |

30 |

|||

|

2 |

Qhov siab |

M |

≤2000 |

||

|

3 |

txheeb ze humidity |

Qhov siab tshaj plaws txhua hnub txheeb ze av noo |

|

95 |

|

|

Qhov siab tshaj txhua hli nruab nrab txheeb ze av noo |

90 |

||||

Tshuab configuration

|

Yam khoom |

Qauv |

Qty |

Chav tsev |

|

|

Intelligent ntsuas imager |

TSI-60 |

1 |

Teeb |

|

|

1 |

Tshuab |

|

1 |

Teeb |

|

2 |

Khoos phis tawj |

|

1 |

Teeb |

|

3 |

Laser tshuab luam ntawv |

|

1 |

Teeb |

|

4 |

Calibration board |

|

1 |

Teeb |

|

5 |

Nias iav |

150*150 |

1 |

Daim |

|

6 |

USB cov ntaub ntawv cable |

|

1 |

Daim |

|

7 |

Software |

|

1 |

Teeb |

|

8 |

Cov lus qhia ua haujlwm |

|

1 |

Teeb |