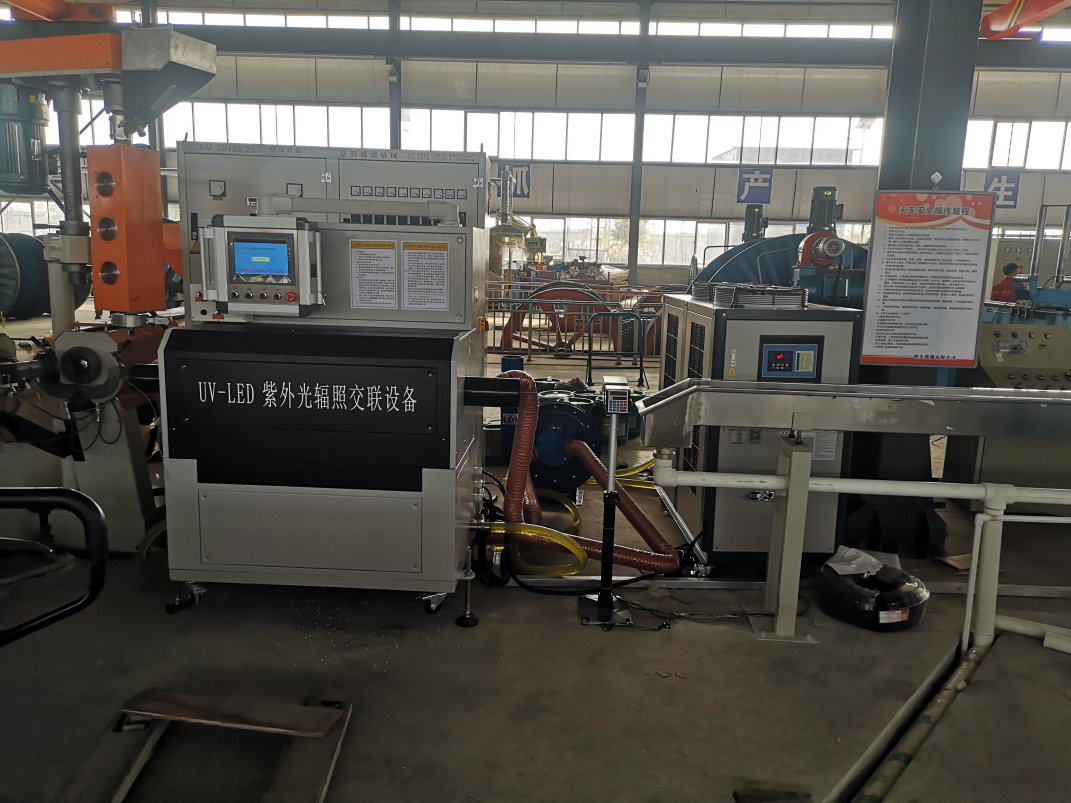

LED Ultraviolet iradiasi Polyolefin Crosslinking Equipment

Deskripsi Produk

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Karakteristik

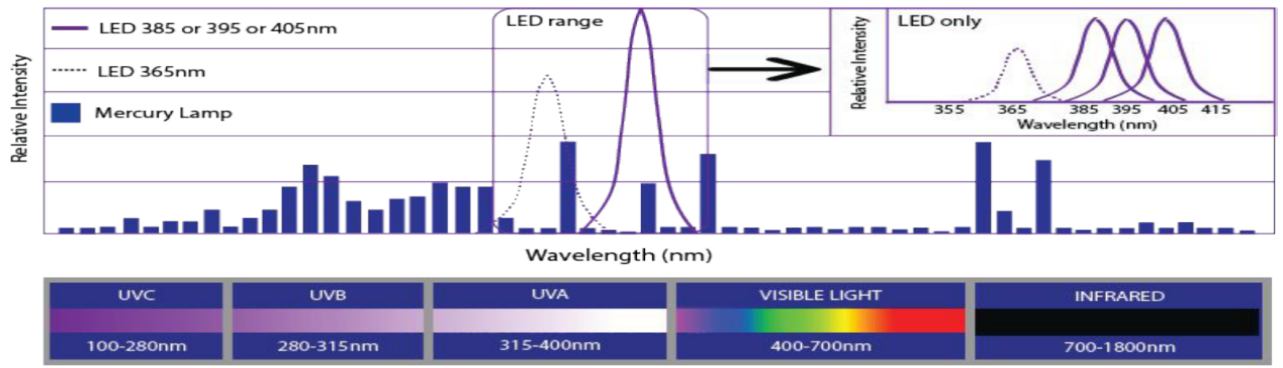

Piranti LED Ultraviolet minangka sumber radiasi ultraviolet paling maju ing donya, kanthi efisiensi energi sing dhuwur (udakara 30%), selektivitas dawa gelombang sing efektif banget (bandwidth dawa gelombang setengah daya 5nm), urip layanan sing dhuwur banget (30,000 jam), infra merah Panas sing sithik. generasi, ora generasi ozon, luwih cocok kanggo ngruwat salib-linking polyolefin salib-disambung lan bahan liyane.

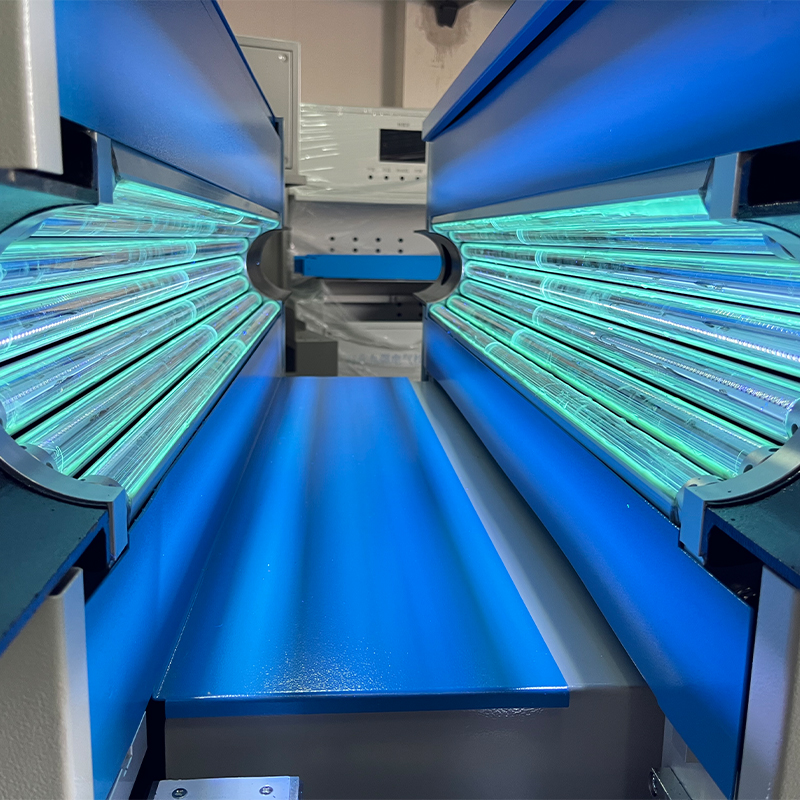

Sumber UV LED nggunakake struktur lensa paten kanggo madhangi lumahing kabel liyane roto-roto lan seragam. Desain landasan ditindakake kanthi kombinasi cairan simulasi piranti lunak Fluent lan tes suhu persimpangan LED, lan papan sirkuit LED dirancang kanthi kombinasi keramik aluminium nitrida lan basa tembaga kanthi kinerja boros panas sing luwih apik, lan nduweni boros panas sing luwih efisien. sistem.

Sumber LED UV nggunakake sumber daya jaringan sing disebarake kanggo nyopir LED UV. Sumber daya nyopir dikemas ing proses pot vakum kanggo njamin linuwih sumber daya. Ing wektu sing padha, bentuk sumber daya nyopir nganggo tata letak sing sempit lan dawa, lan sumber cahya LED jinis dawa nggunakake mode instalasi bali-kanggo-bali kanggo sirkuit LED kanggo nyilikake dawa kabel. Nyadari fungsi sumber cahya urip, mati, lan dimming.

Peralatan salib poliolefin iradiasi UV LED nganggo struktur terowongan rongga bunder, lan dilengkapi sumber lampu LED ultraviolet kanggo mbentuk trowongan kanggo irradiasi wilayah tengah, lan kekuwatan piranti kasebut bisa diatur kanthi bertahap ing kisaran 10 nganti 100%.

Dibandhingake karo peralatan crosslinking iradiasi lampu merkuri tradisional (tradisional trafo-driven UVI / UVI lan elektronik daya-driven UVE-I), elektron accelerator cross-linking, lan silane cross-linking, wis kaluwihan ing ngisor iki:

1 Konsumsi Energi Kurang

UV LED iradiasi polyolefin cross-linking peralatan diinstal daya padha karo 1/4 saka peralatan iradiasi ultraviolet asli, 1/30 saka akselerator elektron, banyu utawa uap banyu perlu dadi panas long-term, lan konsumsi energi saka banyu panas banget. dhuwur.

2 Wektu Singkat

Cross-linking nganggo metode cross-linking ekstrusi online kanggo nyuda proses pangolahan silang silang, dibandhingake karo wektu sing dibutuhake kanggo ngubungake silane sing digodhog utawa dibantu uap lan pangolahan iradiasi sinar elektron sing ditugasake, ngirit wektu manufaktur kabel lan kabel. , utamané darurat Ing completion saka misi, kaluwihan pinunjul.

3 Biaya sing murah

Dibandhingake karo banyu anget cross-linking lan diutus pangolahan iradiasi sinar elektron, rega kabel iradiasi ultraviolet kurang, lan akeh pangolahan rumit suda ing proses produksi, kayata biaya transportasi kabel semi-rampung lan biaya operator cocog.

4 Ora Ozon

Seleksi dawa gelombang sing dhuwur banget, mung ngetokake dawa gelombang sing migunani, ora ana radiasi infra merah, nilai kalori sing kurang; jumlah banget kurang saka radiation katon, ora polusi cahya; ora radiasi ultraviolet dawa gelombang cendhak, ora gawe piala kanggo awak manungsa, nol emisi ozon. Ora perlu cooling aliran hawa penggemar daya dhuwur, ora perlu kanggo saluran udara panas-discharging lan ozon-discharging utamané rumit, mung kudu nyambungake pipa exhaust diameter cilik lan penggemar 2kW kanggo ngilangi asap molekul rendah sing diasilake sajrone ekstrusi insulasi. . Nyegah efek saka iradiasi cahya.

5 Ukuran Cilik, Gampang Dipasang

Cukup nambah jarak kira-kira 2m ing antarane cetakan extruder jalur produksi asli lan tangki banyu anget, lan pasang mesin iradiasi ing jarak 2,5 ~ 3 meter, utawa luwih sempit. Chiller bisa diselehake ing panggonan.

6 Gampang Operate

Mbukak lan nutup struktur trowongan bisu, gampang kanggo ngresiki lan nyandhang ndadékaké, gampang kanggo operate, ora proses rumit, bisa rampung dening operator extruder.

7 Umur dawa lan biaya pangopènan sing murah

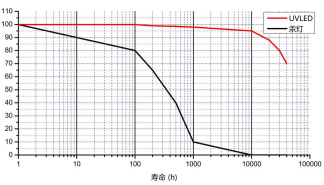

Umur piranti LED kira-kira 30.000 jam, lan umur piranti listrik lan elektronik liyane ora luwih murah tinimbang umur produk listrik lan elektronik umum, tanpa pangopènan sing kerep. Pangopènan reguler kanggo njaga lensa optik tetep resik, bahan konsumsi yaiku tisu industri lan pembersih jelaga, sing bisa ditindakake dening operator. Consumables peralatan iradiasi cahya tradisional yaiku lampu UV lan reflektor, sing kudu diganti ing wektu sing cendhak. Unit iradiasi sinar elektronik uga dibutuhake kanggo njaga tim pangopènan.

8 Ijo

Standar Kualitas Udara Sekitar (GB3095-2012) ing Standar Kebersihan Industri nyatakake yen standar safety ozon yaiku 0.15ppm. Peralatan crosslinking UVLED UV ora bakal ngasilake ozon, dene peralatan lampu merkuri tradisional bakal ngasilake ozon sing akeh. Ozon minangka gas sing mbebayani.

1) macem-macem aplikasi

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Biaya murah

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Gampang kanggo nginstal

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) linuwih dhuwur

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Perbandingan kaluwihan saka iradiasi LED anyar cross-linking lan silane cross-linking:

|

iradiasi ultraviolet LED peralatan |

peralatan silang silang |

Ngirit biaya |

|

|

Biaya bahan |

600 kg sampah saben 90 extruders saben taun |

12 ton sampah saben 90 extruders saben taun |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Daya extruder |

Viskositas materi cilik, konsumsi daya cilik, lan extrusion 90 extruder mung udakara 30KW kanthi kacepetan lengkap. |

Viskositas dhuwur saka materi, konsumsi daya dhuwur, 90 KW kacepetan lengkap extrusion dibutuhake |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Tagihan listrik gawean |

Ora perlu ngresiki extruder |

Resik extruder kanggo setengah jam saben dina |

Ngirit 3400 USD saben taun |

|

Biaya ngubungake silang |

Njupuk 35 meter persegi minangka conto, biaya listrik 80KW kanggo 30.000 meter. |

Njupuk 35 meter persegi minangka conto, butuh 4 jam kanggo 30.000 meter uap cross-linking, lan mbutuhake 200KW listrik. |

Save about 7000 USD in electricity every year |

|

Produktivitas |

Bebarengan ngubungake salib karo extruder, insulasi ekstrusi langsung kabel tanpa pangolahan sekunder |

Digodhog utawa dikukus paling sethithik 4 jam (mbutuhake situs khusus, generator uap) |

Save 8400 USD per year |

|

Kualitas produk |

Nyusut panas kurang saka 4%, ora ana gel sadurunge, permukaan alus |

Nyusut panas sing abot, insulasi bagean salib cilik asring duwe permukaan sing ora lancar lan gel. |

|

|

Investasi peralatan |

Sedheng |

Kurang (kamar uap utawa kolam anget) |

|

|

konsumsi daya |

Kurang (mung butuh 10 KW) |

Dhuwur (mbutuhake pemanasan sing dawa) |

|

|

Biaya produksi |

sedheng |

dhuwur |

|

|

Siklus produksi |

Singkat (online cross-linking) |

Long (mbutuhake pangolahan sekunder) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Perbandingan keuntungan saka iradiasi LED anyar lan sambungan online karo lampu merkuri tekanan dhuwur lawas:

|

mesin iradiasi ultraviolet LED |

Mesin iradiasi lampu merkuri tekanan tinggi lawas |

|

|

konsumsi daya |

Rata-rata kurang saka 15 kW saben jam |

80KW saben jam |

|

Biaya pangopènan |

sedheng |

dhuwur |

|

Kacepetan produksi |

dhuwur |

sedheng |

|

Urip lampu |

30000 jam |

400 jam |

|

Consumables |

Ora |

Lampu, reflektor, kapasitor |

|

Produktivitas |

Extruder ora winates ing kacepetan dhuwur lan bisa diprodhuksi kanthi nguripake lampu. |

Kacepetan produksi alon, efisiensi kurang, sampah tenaga kerja, kudu dipanasake setengah jam sadurunge |

|

Operasi lan ruang lantai |

Operasi prasaja, tilas cilik, ora ngenteni |

Operasi Komplek lan ruang lantai gedhe |

|

Mesin iradiasi LED anyar ngirit biaya listrik 34.000 USD. Biaya tenaga kerja 17.000 USD lan bahan bakar 8.400 USD saben taun tinimbang mesin iradiasi lampu merkuri tekanan tinggi lawas. |

||

Kontras spektral LED lan lampu merkuri

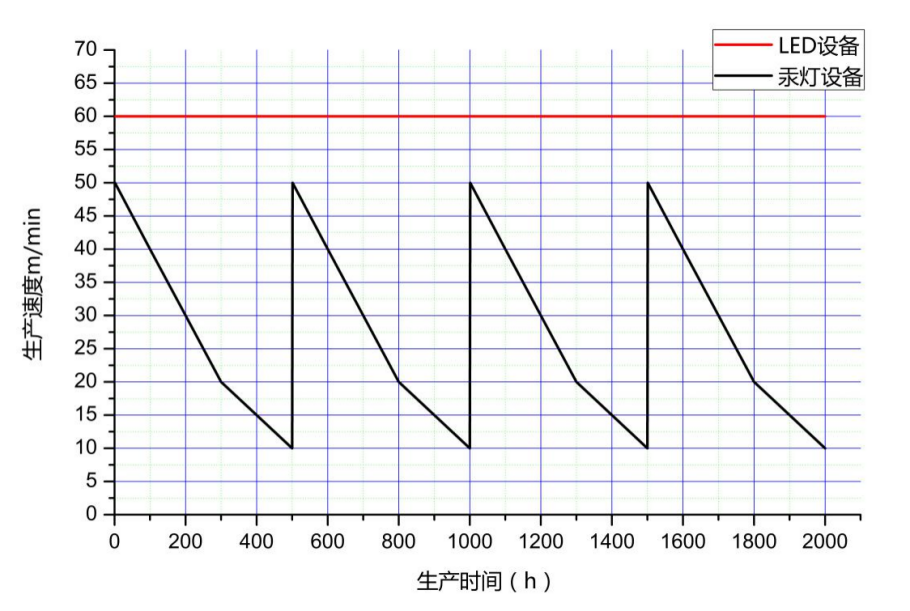

LED lan Mercury lamp urip comparison

Perbandingan kurva kacepetan produksi antarane peralatan iradiasi lampu merkuri lan peralatan iradiasi LED

Parameter Kinerja Peralatan Iradiasi Iradiasi UV-LED:

- 1. Daya: sistem telung fase limang kabel (380V + N + ground)

- 2. Total daya mesin diinstal: 20kW

- 3. Dhiameter paling apik saka area iradiasi: 30mm

4. dawa iradiasi efektif: 1m

- 5. Manik-manik lampu nggunakake sumber cahya sing diimpor paling dhuwur ing donya, lensa nggunakake kuarsa sing diimpor, saengga nduweni mundhut energi sing luwih murah, pesawat lampu nggunakake teknologi pendinginan cair, supaya sumber cahya LED nduweni umur layanan sing luwih suwe.

- 6. Sumber daya nganggo sumber daya tahan banyu Taiwan Mingwei, sing dilindhungi dening teknologi vakum potting, kanthi kakehan, sirkuit cendhak, liwat saiki, liwat voltase lan liwat pangayoman suhu.

7. Output daya optik bisa diatur kanthi sewenang-wenang saka 10% -100%, miturut kabutuhan pelanggan kanggo nyetel daya apa wae.

- 7. Urip sumber cahya: 30.000 jam (disedhiyakake dening pabrikan) Intensitas cahya output dikurangi dadi 70% (efisiensi mudhun nganti 70%). Wektu panggunaan yaiku 30,000 jam, lan wektu pitungan yaiku 6 ~ 10 taun.

9. Ukuran kothak iradiasi: 1660mm * 960mm * 1730mm (dawa x jembaré x dhuwur)

Fitur struktur peralatan:

- 1. struktur trowongan mbukak lan nutup bisu, gampang operate lan resik;

- 2. Nggunakake antarmuka wong-mesin tutul sing cerdas, data ngawasi, lan setelan daya tombol operasi wis rampung ing antarmuka layar tutul;

- 3. Fungsi kontrol layar demek lan tombol wiwit urip bebarengan kanthi kapisah;

- 4. Cara cooling digawe adhem dening chiller, lan medium sirkulasi digawe saka antifreeze khusus kanggo mobil;

- 5. Mekanisme mbusak kumelun njaba, dibuwang liwat saluran udara ruangan

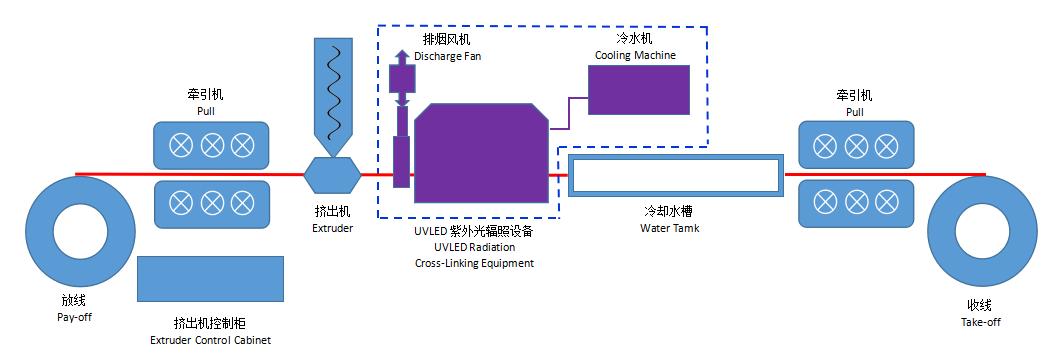

Tata letak piranti

Kacepetan produksi bahan iradiasi polietilen sing disambung silang

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Kepala mesin |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

Ketebalan nominal isolasi (mm)

|

Kecepatan produksi alami (m/min)

|

Ekstensi panas (%)

|

Ewah-ewahan bentuk permanen |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Kacepetan produksi bahan iradiasi bebas halogen asap rendah

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Kepala mesin |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

Ketebalan nominal isolasi (mm)

|

Kecepatan produksi alami (m/min)

|

Ekstensi panas (%)

|

Ewah-ewahan bentuk permanen |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Cathetan: Amarga peralatan extrusion lan proses produksi lan bahan kabel saka macem-macem perusahaan beda, kacepetan ekstrusi bakal beda. 90 extruder ora winates.

Instalasi ing situs mesin salib iradiasi sinar ultraviolet LED