Mesin Uji Tarik Horizontal Servo TXWL-600 Electro-Hydraulic

Deskripsi Produk

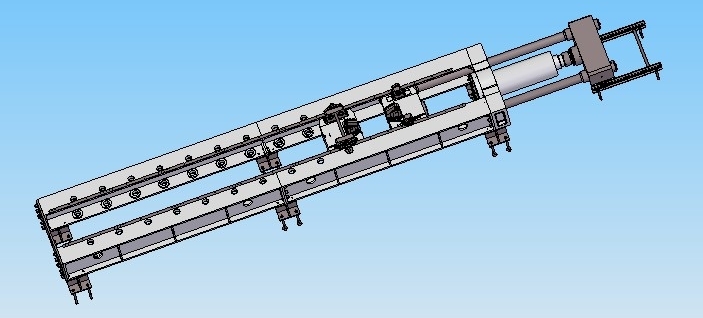

TXWL-600 electro-hydraulic servo horisontal testing tensile machine adopts horisontal struktur pigura, siji rod pindho tumindak silinder piston exerts pasukan test, lan sistem kontrol komputer nyadari kontrol otomatis saka proses test dening Ngontrol tutup servo lan komponen liyane, test data diklumpukake kanthi sensor beban lan dikirim menyang komputer, sistem kanthi otomatis nganalisa, ngolah lan nyimpen asil tes, lan printer bisa langsung nyithak laporan tes sing dibutuhake. Mesin iki utamane digunakake kanggo tes tensile saka tali kawat baja, minangka produksi modern riset ilmiah lan piwulang lan industri liyane kanggo nyukupi syarat peralatan uji sing cocog.

Katrangan Mesin

1. Sistem host

Bagean mesin utama utamane kalebu pigura mesin utama, kursi silinder minyak, silinder minyak, balok obah, kursi chuck ngarep lan mburi lan sensor beban. Bisa nindakake tes tensile kanthi beban maksimal 600kN ing sampel.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Wilayah tes dilengkapi tutup protèktif, sing bisa nglindhungi safety personel tes kanthi efektif.

2. Sistem sumber lenga

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3. Bagian Listrik

Kontrol listrik diatur ing area operasi tes, lan ana panel operasi sing dirancang khusus kanggo nggawe kabeh jinis operasi kanthi cepet. Komponen listrik saka merek terkenal internasional, kanthi kinerja sing stabil lan kualitas sing bisa dipercaya.

Sistem Software:

(1) Adhedhasar platform operasi Windows XP kanthi fungsi sing bisa diprogram, kontrol pasukan tes tingkat sing padha, kontrol pamindahan tingkat sing padha, nyekeli pasukan tes, nyekel pamindahan lan mode tes liyane bisa digabungake kanthi kekarepan kanggo nyukupi syarat macem-macem metode tes. kanggo ombone maksimum, lan éling macem-macem tampilan data, drawing kurva, Processing data, panyimpenan lan printing fungsi dibutuhake kanggo test.

(2) Kirimi sinyal kontrol menyang katup servo liwat komputer kanggo ngontrol bukaan lan arah katup servo, saéngga ngontrol aliran menyang silinder, lan nyadari kontrol pasukan tes tingkat sing padha, pamindahan sing padha, lan liya-liyane. .

(3) Dilengkapi karo rong puteran kontrol loop tertutup saka gaya tes lan pamindahan.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Antarmuka utama nduweni kabeh fungsi operasi saben dina tes, kayata entri informasi sampel, pilihan sampel, gambar kurva, tampilan data, pangolahan data, analisis data, operasi tes, lan liya-liyane. cepet.

(6) Data kasebut bisa dikirim menyang printer kanggo nyithak laporan tes.

(7) Manajemen hirarki sistem, paramèter sistem kabeh mbukak kanggo pangguna ahli, njamin keluwesan lan linuwih sistem.

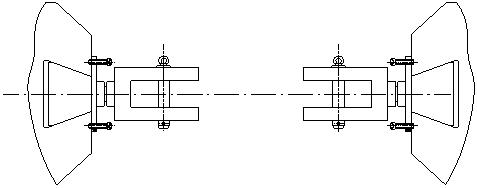

4. Test Aksesoris

Dilengkapi karo aksesoris test tali kabel (ndeleng ngisor) lan aksesoris liyane diprodhuksi miturut standar sing diwenehake dening pangguna utawa syarat tensile saka sampel.

5. Piranti Protection Safety

(1) Proteksi kakehan nalika pasukan test ngluwihi 2% kanggo 5% saka pasukan test maksimum utawa nilai pesawat.

(2) Proteksi stroke nalika piston pindhah menyang posisi watesan.

(3) Kanthi suhu lenga, tingkat Cairan lan pangayoman resistance lenga lan piranti indikasi.

(4) Ruang tes duwe tutup protèktif kanggo nyegah sampel saka pecah lan tiba metu.

(5) Nalika ana darurat, pencet tombol mandeg darurat ing kabinèt kontrol langsung

Parameter teknis

1. Gaya tes maksimal: 600kN

2. Range pengukuran kekuatan tes: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4. Ruang uji tarik (ora kalebu stroke piston): 20mm ~ 12000mm

5. Piston stroke: 1000mm

6. Kacepetan kerja maksimal piston: 100 mm / min

7. Deformasi extensometer akurasi: 0.01mm

8. Dimensi mesin utama (mm): 16000 (L) x 1300 (W) x 1000 (H) (ora kalebu tutup pelindung)