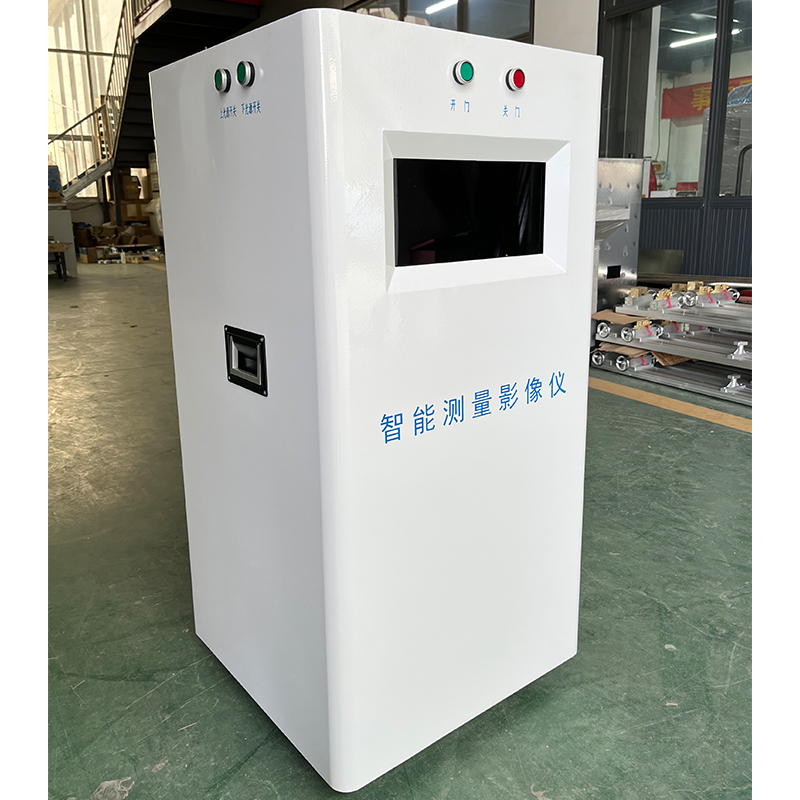

FYTY Series Intelligent Mensurae Imager

depictio producti

Commodo occurrit: IEC60811, TB2809-2017, GB/T2951

The intelligent measuring imager is an independently developed measuring system that uses visual inspection methods to measure the structure data of wires and cables. The product is designed and manufactured in accordance with the measurement requirements of the thickness and dimensions of the IEC 60811-1-1(2001)/GB/T2951.11-2008/TB2809-2017 (the implementation standard for locomotive contact wires)standards.

Per compositionem machinae visionis et imaginis computatoris technologiae technologiae, hoc productum potest celeriter et accurate comprehendere crassitudinem, diametri exterioris, eccentricitatis, concentricitatis, ellipticitatis, aliarumque mensurarum insulationis et vaginae plurium generum filis et funibus in vexillo determinatis; etiam metire crucem-sectionalem aream cuiuslibet lavacri et conductoris valoris. Mensura accuratio instrumenti longe melior est quam accuratio a norma requiritur.

Munera et Features

Using computer vision technology, inspection is rapid and timely, far exceeding the measurement speed of manual projectors and reading microscopes. Automatic inspection of the structural parameters of the cable according to the inspection shape selected by the user enables more accurate inspection accuracy than manual measurement and the measurement specifications required by IEC 60811-1-1 (2001). Use LED parallel light sources to improve lighting uniformity and life to ensure continuous and stable light. Fast measurement data can quickly guide product production, ensure product quality, and can reduce the cost of cable production materials, reduce the error rate of human measurement and improve measuring efficiency.

Vestigia ultimae IEC filum et cable signa et tentare modos in tempore. Liberae programmae upgrades utentibus praebentur, et corporis compages professionalis designata mensuras rationabiles et certas efficit. Utens summus effectus industriae digitalis camerae cum 10 megapixel (1-80mm) et 20 megapixel (80-140mm) CMOS sensoriis quattuor diversis coetibus camerarum varias filum et funem insulationis et vaginae magnitudinis datas ab 1mm diametro ad 140mm diametri deprehendere potest.

Configurationis

Summus praecisio CCD et lens adhibentur ut comparatio imaginum machinas ad imaginandi et sampling perficiendas ut accurate et stabilis specimen experiatur et efficientiam meliorem efficiat.

Mensuratio-is non-contactus, independenter et obiective obiectum probatum metitur, efficaciter dubitationem mensurae manualis vitans.

|

Item |

Systema operating mensuræ intelligentium imager |

|||

|

Test parametri |

Crassitudo, diametri exterioris et elongationis notitiae materiarum cabulorum et e vaginarum velitarum et ruderum opticorum |

|||

|

Sample type |

Insulatio et vagina materiarum funium et ruderum opticorum (elastomorum, chloridi polyvinylorum, polyethylenae, polypropylenae, etc.). |

|||

|

range mensuræ |

1-10mm |

10-30mm |

30-80mm |

80-140mm |

|

Camera |

No.1 |

No.2 |

No.3 |

No.4 |

|

Sensor type |

CMOS progressivum scan |

CMOS progressivum scan |

CMOS progressivum scan |

CMOS progressivum scan |

|

Lens pixel |

X decies |

X decies |

X decies |

XX decies |

|

Imago resolutio |

2592*2600 |

2592*2600 |

2704*2700 |

3488*3500 |

|

Propono resolutio |

0.001mm |

|||

|

Mensuratio repeatability (mm) |

≤0.002 |

≤0.005 |

≤0.01 |

≤0.03 |

|

Measurement accuracy (μm) |

4+L/100 |

8+L/100 |

20+L/100 |

40+L/100 |

|

Lens mutandi |

Sponte flectendum lens |

|||

|

Test tempus |

≤10sec |

|||

|

Test ratio |

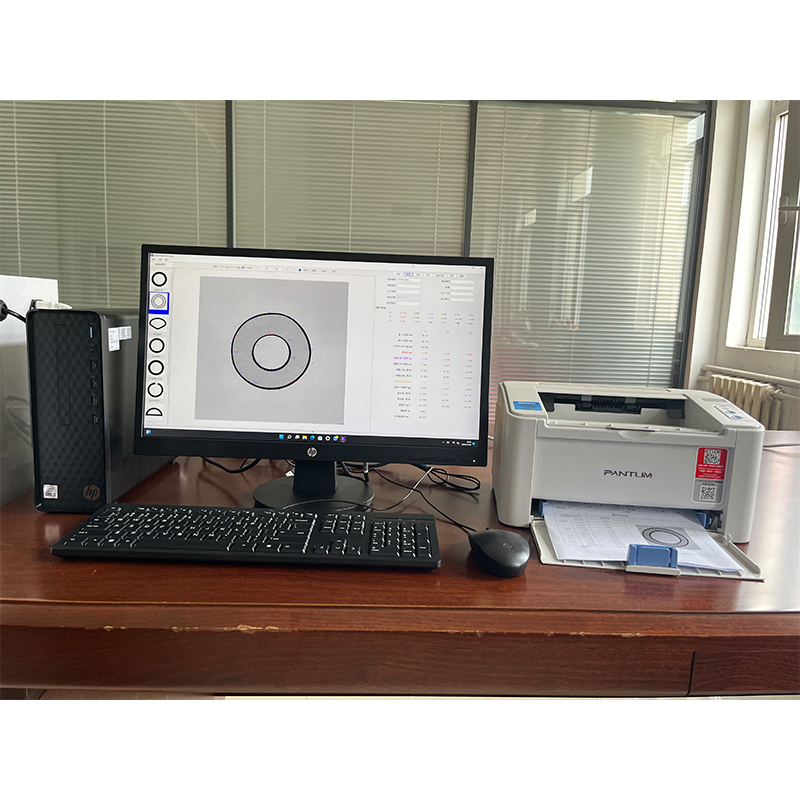

Mensura strepita, preme pyga mensurae cum mure, programmata automatice probabuntur, omnes parametri uno tempore probabuntur, relatio probata sponte edetur, et notitia in automatice datorum reponenda est.

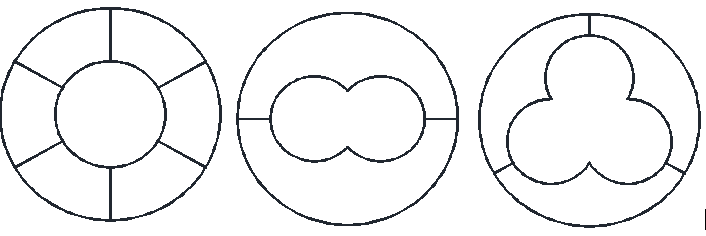

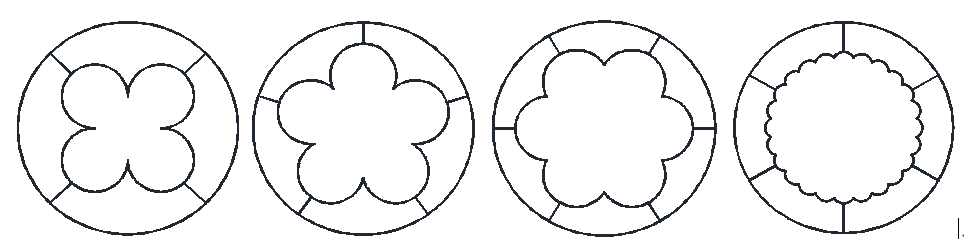

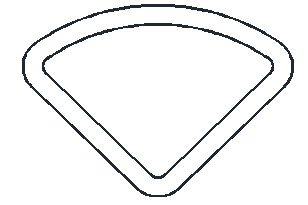

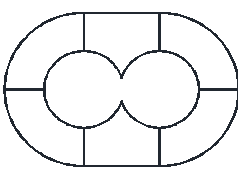

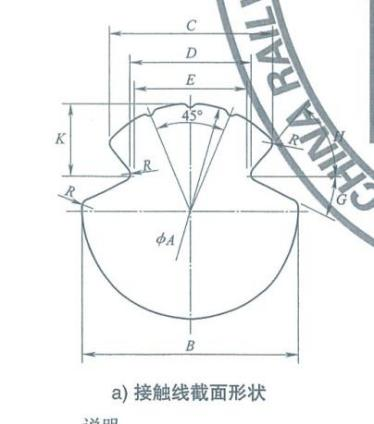

Testis software: 1. Cuniculum testabile velit ac figura vaginae includunt IEC60811. Figura 1 ad figuram 11 . -Insulation et involucrum crassitudine mensurae (per superficiem interiorem) Insulation crassitudine measurement (sector informibus conductor) -Insulation crassitudine measurement (destitutus conductor) -Insulation crassitudine mensurae (irregulariter exteriore) ⑤Insulation crassitudine mensurae (plana duplici core non circumfusa flexilis) -Sheath crassitudine mensurae (irregulariter circularis superficies interioris) -Sheath crassitudine mensurae (non-circularis superficies interioris) -Sheath crassitudine mensurae (irregulariter exteriore) -Sheath crassitudine mensurae (coro funiculus duplex in plana vaginis) -Sheath crassitudine mensurae (multi-core plana funem) TB2809-2017 ( vexillum exsecutivum pro filum contactus motivum ) sectio magnitudinis et mensurae angulus .

2. Suscipe experimentum trium figurarum coextrusionis craticulae funis medii et funis magni voltage.

3.Insulation et vagina test items Maximum crassitudinis, minimae crassitudinis et mediocris crassitudinis. Maximum diametrum, diam minimum, diam mediocris, area crucis-sectional. Eccentricitas, concentricitas, ovalitas (orbicularis).

4.Conductor referat crucem-Lorem area

5. Mensuratio methodi independenter disposita secundum requisita 3C: requisita 1.9.2 in GB/t5023.2-2008: "accipe tres sectiones exemplorum pro unaquaque filo insulato nucleo, metire valorem mediocris valorum 18 valorum (expressi in mm), ad duo loca decimalia computa, et rotundum secundum praescripta sequentia (vide normas regulas circumactionis vexillum), et sume hunc valorem ut mediocris valor crassitudinis velit. Relatio singularis 3C generari potest, cum determinatione munus absolute.

6.Manual measurement function: even if you meet the section shape of wire and cable insulation thickness not listed in the standard, the manual measurement function is added in the software. Just click the position to be measured in the section view, that is, the point-to-point length will be displayed automatically. After the measurement, the minimum thickness and average thickness of these positions can be displayed automatically。 |

|||

|

Calibration munus |

Vexillum anulum calibrationis tabula praebetur, quae ad calibrationem instrumenti adhiberi potest |

|||

|

Vita longa lux fons |

Altus densitas DUXERIT lucis parallelae fontem, lumen monochromaticum, spargens et elucidans formam obiecti mensurati quam maxime. Singularis 90 gradus angulus auxiliaris crucis luminis fons designans exempla opaca metiri potest. |

|||

|

Lux systematis iter |

Chassis plene signatus, verticalis pulvis-probationis viam opticam systematis ad refractionem opticam reducendam adoptat. |

|||

|

Cubiculum lucis mensuræ |

Totus lucis locus nigrae considerationem diffusam reducit, lucis impedimentum erraticum excludit, erroresque falsos evitat. |

|||

Source lucis parametri

|

Item |

Type |

Color |

Illuminantia |

|

Parallel backlight |

LED |

album |

9000-11000LUX |

|

2 auxilia crucis lucis fontes |

LED |

album |

9000-11000LUX |

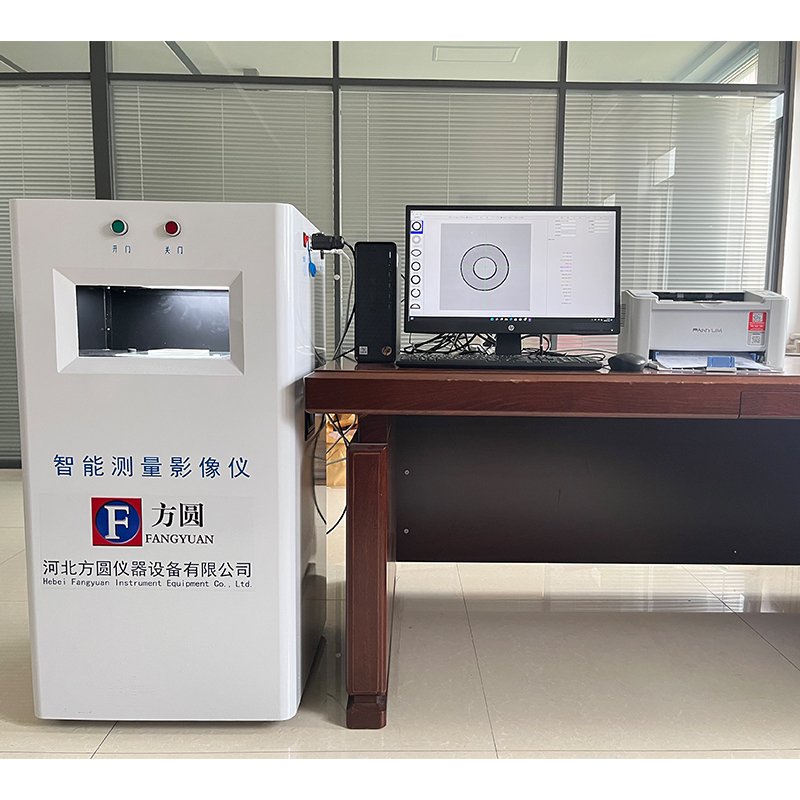

Computatrum

Processus Intel G6400, quad-core, 4.0GHz, 4G memoria, 1TG ferreus coegi, ostentatio 21.5 inch, systema operandi window10

Printer

Laser printer, A4 paper, black and white printing

Sample

Circum pieces (7 types)

Regular ring Double-core round Three-core round

Four-core round Five-core round Six-core round Irregular ring

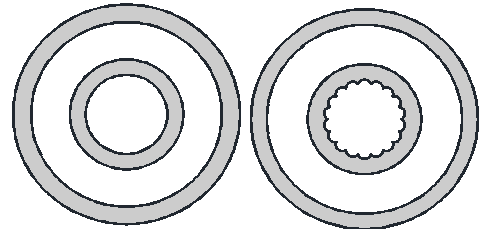

Tres accumsan anulum (II genera)

Descriptio: Internum lenis anulus et anulus lappa internus

Smooth inner ring Internal burr ring

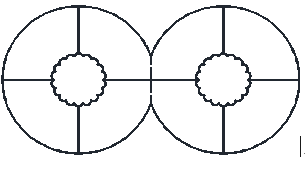

Telescopium (1 type)

Sector (1 type)

Duplex core plana (I type)

Irregulares superficies circum (II genera)

Single-layer three-core irregular circles Single-layer irregular circles inside and outside

TB2809-2017 (Executive Standard for Locomotive Contact Wire) Sectional Dimensiones and Angle Mensuratio

Mensuratio velit iacuit opaci duplex iacuit vel triplex iacuit Flexilis vaginatus summus intentione funis

Condiciones uti Environmental

|

Nec. |

Item |

Unitas |

Project unitas requiritur valorem |

||

|

1 |

Ambientium, temperatus |

Maximum cotidie temperatus |

℃ |

+40 |

|

|

Minimum cotidie temperatus |

-10 |

||||

|

Maximum cotidie temperamentum differentia |

℃ |

30 |

|||

|

2 |

altitudo |

M |

≤2000 |

||

|

3 |

Relativum humiditas |

Maximum cotidie humidum relativum |

|

95 |

|

|

Maximum menstrua mediocris inter humiditatem |

90 |

||||

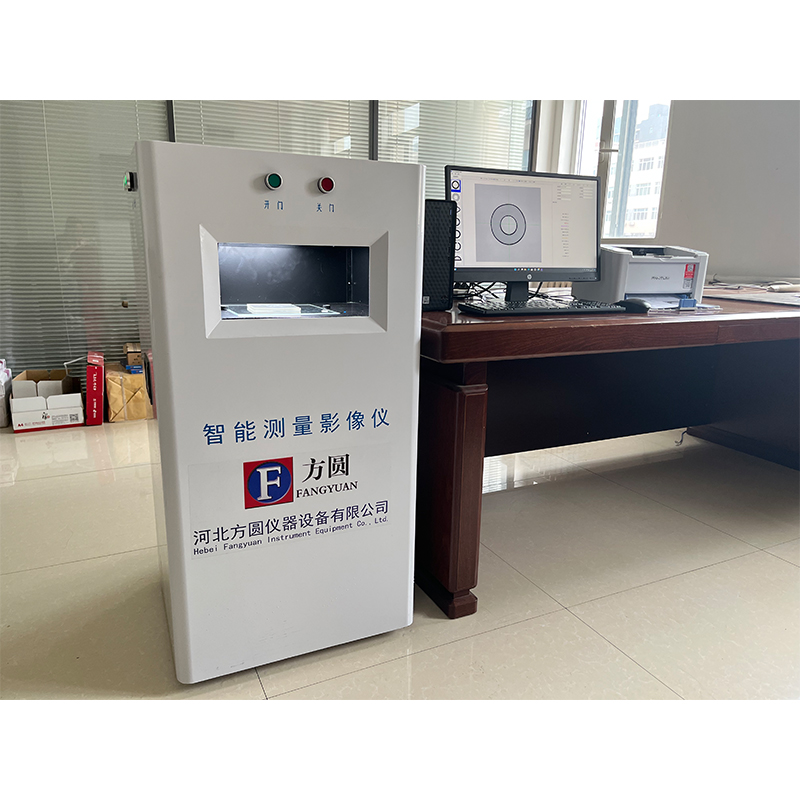

Configuratione machina

|

Item |

Model |

Qty |

Unitas |

|

|

Intelligentes mensuræ imager |

FYTY-LX |

1 |

Set |

|

|

1 |

machina |

|

1 |

Set |

|

2 |

Computatrum |

|

1 |

Set |

|

3 |

Laser printer |

|

1 |

Set |

|

4 |

Calibration tabula |

|

1 |

Set |

|

5 |

Pressum vitrum |

150*150 |

1 |

Piece |

|

6 |

USB data cable |

|

1 |

Piece |

|

7 |

Software |

|

1 |

Set |

|

8 |

Operans mandatum |

|

1 |

Set |