DUXERIT Ultraviolet Irradiatio Polyolefin Crosslinking Equipment

depictio producti

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

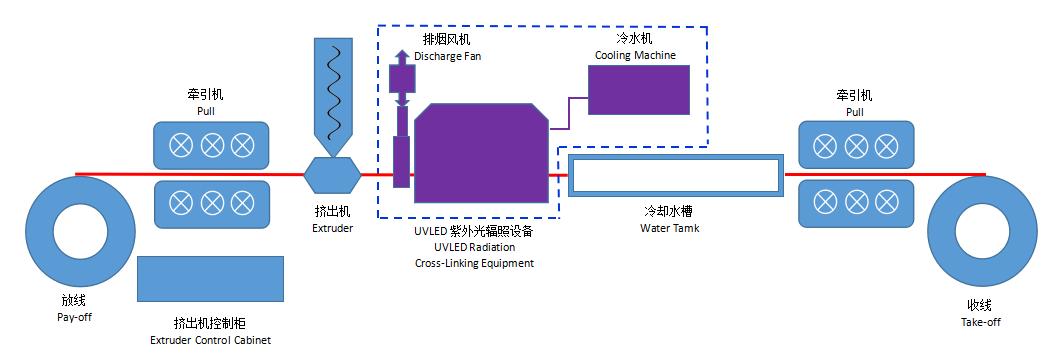

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Characteres

Fabrica ultraviolacea DUCTUS est antecedens fons radiorum ultraviolatarum in mundo, magna vis efficientiae (circiter 30%), altissimam selectivity necem efficacissimam (dimidiam potentiae necem 5nm), summa opera vitae (30.000 horae), calor humilis infrared. generatio, nulla ozona generatio, magis apta ad sanationem crucis-connexionis polyolefin et alia materia.

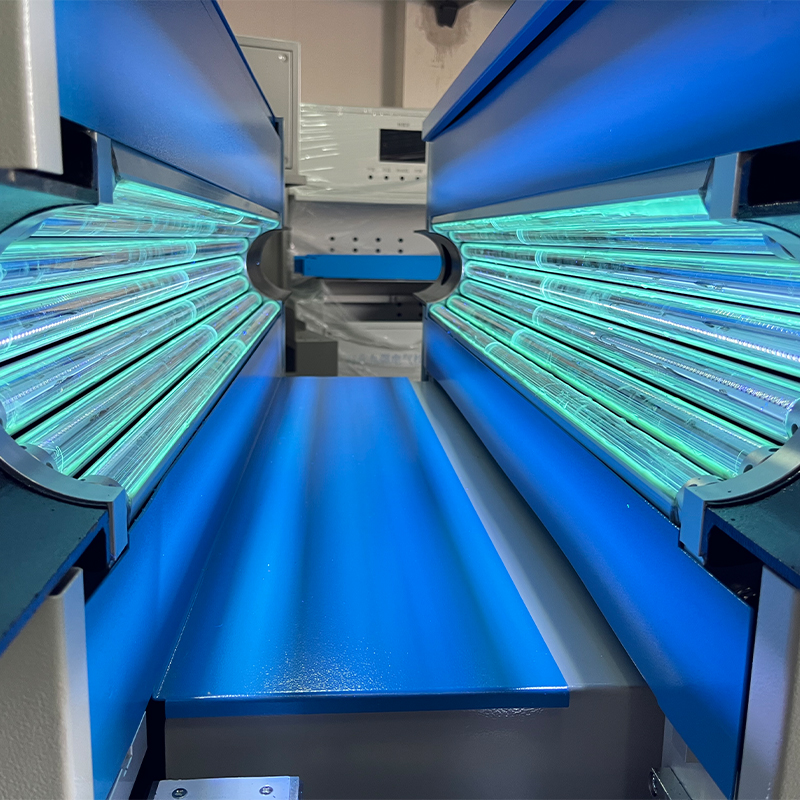

Fons UV LED structura lens patente utitur ad illustrandam superficiem funis aequaliter et aequaliter. Substratum consilium fit per compositionem Fluent software simulationis fluidi et commissurae temperaturae experimentum DUCTUS, et tabula circuli ducatur per coniunctionem aluminii nitride ceramici et aeris basin cum meliori caloris dissipatione peractam, et efficaciorem caloris dissipationem habet. ratio.

Fons UV DUCTUS distributo retis potentiae fonte utitur ad UV LED depellendam. Copia potentiae incessus in vacuo potting processu sarcinatur, ut copia certa potentiae conservetur. Eodem tempore, figura potentiae agentis, extensionem angustam et longam adhibet, et fons lucis longi-typus DUCTUS modum institutionis dorsi adoptat ad modum ductum circuii ad extenuandum longitudinis filum. Excipe iubar's, abi, et munera purulenta.

UV DUCTUS irradiatio polyolefin instrumenti crucis connexionis in modum cavitatis cuniculi circularis structuram capit, et cum lucis ultraviolaceo ductus fonte instructus est cuniculum ad mediam regionem irradiandam efformandam, et vis fabricae gradatim in 10 latitudinem collocari potest. ad C%.

Comparatus cum tralaticio mercurii lampadis genus irradiationis transmissionis instrumentorum (traditionalis transmutatoris UVI/UVII agitatae et electronic potentiae agitatae UVE-I), electronico acceleratori transversalis coniunctio, et cruces silanae nexus, sequentia commoda habet:

I Maximum Energy Consummatio

UV LED irradiatio polyolefin crucis-coniunctio cum instrumento potentiae inaugurato aequiparatur 1/4 instrumenti irradiationis originalis ultravioli, electronici acceleratoris 1/30, aqua vel aqua vapor diu-term eget calefactio, et vis consumptio aquae calefactionis valde est. altum.

II Brevis Tempus

Crux-coniunctio inducit modum extrutionis crucis-connexionis online modum reducendi processus processus crucis-connexionis subsequentis, comparato tempore requisiti ad cruces silanae cocti vel vaporis adiuti, nexa et electronico trabes irradiationis dispensando commissa, filum ac funem temporis fabricandi salvificam. praesertim utili Completio missionis, commoda significantia.

III Minimum cost

Comparatus cum aqua calida transversim coniungens et electronico trabem irradiationis processus commisit, pretium funis irradiationis ultravioli demissum est, et multi complicati processus in processu productionis reducuntur, ut vecturae sumptus funes semi-perfecti et sumptus operantis respondentes.

4 Non Ozone

Praealta necem selectivity, solum utiles aequalitates emittit, radiorum ultrarubrum nullum, vile calorificum valorem; moles valde gravis radiorum visibilium, nulla lux pollutio; nullum breve radiatio ultraviolacea necem, nullum corpori humano detrimentum, nulla ozona emissio. Non opus est summus potentiae ventilationis ventilationis infrigidatio, nulla indigentia ductus ozonis-aeris et ozonis diffugientis caloris peculiariter perplexus, tantum opus est coniungere parvam diametris exhauriendi fistulam et 2kW ventilabrum ad excludendum fumum humilem-molencularium in exstructione velitationis genitum. . Effectus lucis irradiatio praeveni.

V Parvus, Securus Install

Simpliciter adde distantiam circiter 2m inter productionem primigeniam lineae extruderis formae et aquae calidae piscinam, et machinam irradiationem pone in spatio 2.5~3 metrorum in latitudine, seu angustiore. Frigidus ilico collocari potest.

VI Securus operari

Silens aperiens et claudens structuram cuniculi, facile ad mundum et ad induendum ducit, facile ad operandum, nullus processus multiplex, ab extruder operator perfici potest.

VII Long Vita Et Minimum Sustentacionem Pretium

Vita ductus machinis est circiter 30,000 horarum, et vita aliarum electricum et electronicarum machinis non minor est quam vita productorum electricorum communis et electronicorum, sine frequenti sustentatione. Iusta sustentatio ad servandum lens optica munda, consumables sunt industriales abstergit et fuligo cleans, quod ab operante fieri potest. In lucem traditionalem irradiationem instrumentorum consumabilium sunt UV lampades et ponderum, quae brevi tempore reponi debent. Radius electronicus irradiatio unitatis etiam ad equos sustentandos requiritur.

8 Green

Ambiens Air Quality Standard (GB3095-2012) in Industrial Hygiene Latin ponit vexillum salutis ozono esse 0.15ppm. UVLED UV apparatum transversim ozonem non generabunt, cum traditum instrumentum mercurii lucernae magnam quantitatem ozonis generabit. Ozona gas noxia est.

I) amplis applications

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

II) Maximum pretium

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

III) Securus install

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

IV) High reliability

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Comparatio commodorum novarum irradiationis ductae crucis-coniunctio et silanae crucis-coniunctio:

|

DUXERIT ultraviolet irradiationem armorum |

Silane crosslinking apparatu |

Sumptus peculi |

|

|

Materia sumptibus |

DC kg vastum per XC extruders anno |

XII talenta vastum per XC extruders anno |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Extruder potentia |

Viscositas materiae parva est, potentia consummatio parva est, et extruder extructio 90 circiter 30KW in pleno cursu tantum est. |

Alta viscositas materiae, alta potentia consummatio, 90 KW plena celeritatis extrusio requiritur |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Artificialis electricae libellum |

Non opus est ut extruder emundare |

Emundare extruder per semihoram cotidie |

Nisi MMMCD USD anno |

|

Crux-conjunctio cost |

Accipiens XXXV metra quadrata in exemplum, electricitatis sumptus 80KW pro 30.000 metris est. |

Sumens exemplum 35 quadratum metrorum, accipit 4 horas pro 30.000 metris vaporis connexionis, et requirit 200KW electricitatis. |

Save about 7000 USD in electricity every year |

|

Productivity |

Simul transversis coniungens cum extruder, velit evulsio directe funem sine processus secundario |

Coctum vel vapore ad minus IV horas (site requirit specialem, vaporem generantis) |

Save 8400 USD per year |

|

Product qualitas |

Calor DECREMENTUM minus quam 4%, nulla prior gel, superficies plana |

Gravis calor DECREMENTUM, parva insulatio transversalis saepe superficies non levis et gel . habet |

|

|

apparatu investment |

Medium |

Humilis (locus vaporis vel stagnum calidum) |

|

|

Potentia consummatio |

Humilis (tantum X KW) |

Princeps (requirit calefactionem longam) |

|

|

Sumptus productionis |

low |

Summus |

|

|

Productio exolvuntur |

Brevis (connexio crucis-online) |

Longum (secundum processus requirit) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Comparatio commodorum novae irradiationis DUCTUS et nexus online cum veteri lucerna alta premente Mercurio:

|

DUXERIT machina irradiatio ultraviolacea |

Vetus princeps pressura mercurii lucerna irradiatio machinae |

|

|

Potentia consummatio |

Mediocris minus quam XV kW per hora |

80KW singulis horis |

|

Tutela pretium |

low |

Summus |

|

Productio celeritas |

Summus |

low |

|

Lucerna vitae |

(XXX) horis |

CD horis |

|

Consumables |

No |

Lucerna, ponderator, capacitor . |

|

Productivity |

Extruder non limitatur ad altam celeritatem et produci potest per conversionem in lucem. |

Tardus celeritas productio, humilis efficientia, vastitas laboris, necesse est ut media hora in antecessum preheat |

|

Operatio et area spatium |

Simplex operatio, parvum vestigium, non expectatio |

Complex operatio et magna area spatium |

|

DUXERIT novam machinam irradiationem liberat: 34,000 USD electricitatis gratuita. 17,000 USD gratuita laboris et 8,400 USD per annum consumabilia quam vetus summus pressura mercurialis machinae lampadis irradiationis. |

||

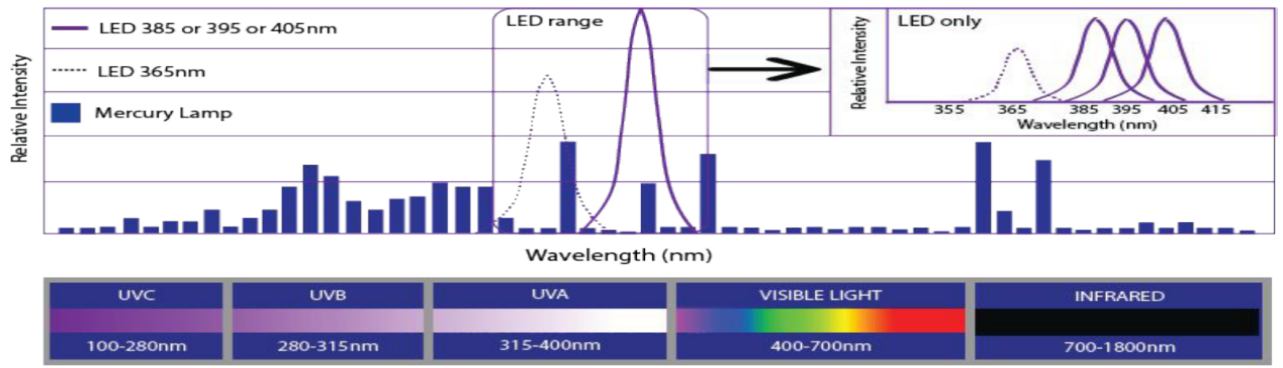

DUCTUS et mercurialis lucerna spectris antithesis

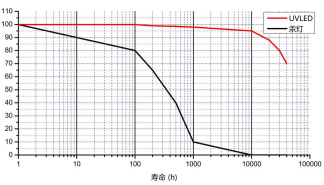

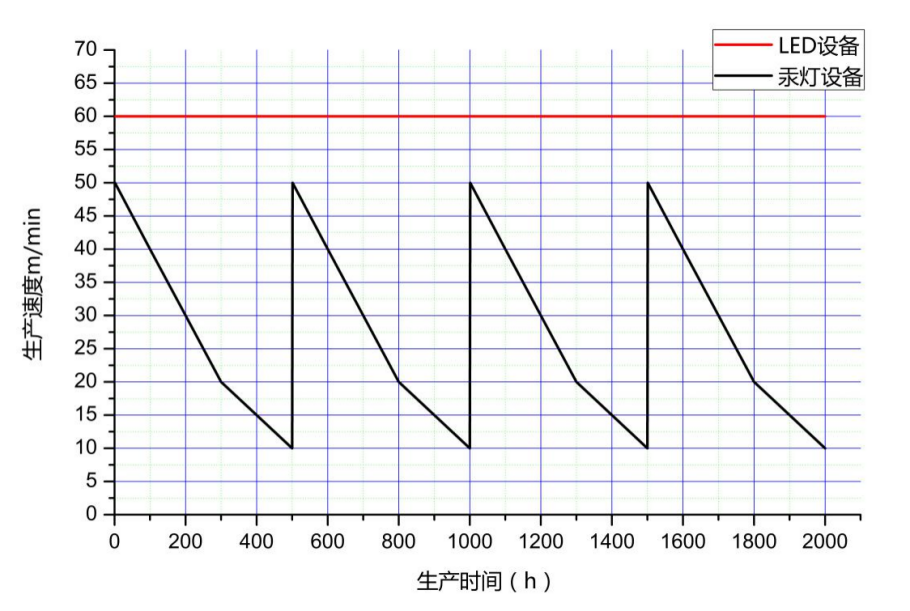

LUXUS ET MERCURIUS Lucerna vita comparationis

Comparatio celeritatis productionis curvae inter apparatum mercurii lampadis irradiationis et armorum irradiationis DUXERIT

UV-DUXERIT Iradiatio Crosslinking Equipment euismod Morbi:

- 1. Power: three-phase five-filum system (380V + N + ground)

- 2. Totalis potentia apparatus installed: 20kW

- 3. Diameter optimus area irradiationis: 30mm

4. efficax irradiatio longitudo: 1m

- 5. Lucerna globuli mundi culmen importato luminis utuntur, lens utitur vicus importato, ita ut detrimentum industriae inferioris habeat, lucerna technologiae refrigerationis liquido utitur, ita ut fons lucis ductus longiorem vitam serviat.

- VI. Copia potentiae IMPERVALIS Mingwei Taiwan vim copiae capit, quae technicae potting vacui tutatur, cum onere, ambitu brevi, super current, super intentione et tutela temperatura.

7. Potestas optica output ex 10% -100% ad libitum componi potest, secundum emptores necessitates ad omnem potestatem accommodandam.

- 7. Fons lucis vita: 30.000 horarum (provisum a fabrica) Intensio levis intensio ad 70% extenuatur (efficientia guttae ad 70%). Usus temporis est 30,000 horarum, et tempus calculi est 6~10 annorum.

9. Irradiatio arca magnitudinis: 1660mm* 960mm* 1730mm (longitudo x latitudo altitudinis x)

Apparatus structurae lineamenta:

- 1. Tacita aperiendi et claudendi cuniculi structuram, facilem ad operandum ac nitidum;

- 2. Intelligens tactus machinae instrumenti hominis, data vigilantia, et uncinis globulorum potentiae operativae omnes peractae sunt in screen interfaciei tactus;

- 3. De functionibus et globulis televisificis incipiunt separatim coexistere;

- 4. Methodus refrigerationis refrigeratur a frigidiore, et medium circulatio fit ex speciali antifreeze pro autocinetis;

- 5. Fumus externus remotionis mechanismi, per ductus aëris emissi

Apparatus layout

Productio celeritas crucis-coniunctum polyethylene materia irradiata

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Machina caput |

||

|

135℃ |

150℃ |

160℃ |

175 |

180℃ |

180℃ |

||

|

Conductor cross section (mm²) |

Nulla nomina crassitudine (mm)

|

Naturalis celeritas productio (m/min)

|

Calor extensio (%)

|

Deformatio permanens |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Humilis fumus halogen-liberum irradiatio materialis celeritatis productio

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Machina caput |

||

|

135℃ |

150℃ |

160℃ |

175 |

180℃ |

180℃ |

||

|

Conductor cross section (mm²)

|

Nulla nomina crassitudine (mm)

|

Naturalis celeritas productio (m/min)

|

Calor extensio (%)

|

Deformatio permanens |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Animadvertit: Quia extrusio instrumentorum et processuum productionis et funerum materiarum diversorum inceptorum diversae sunt, extrusio celeritas diversa erit. Extruder 90 quod non limitatur.

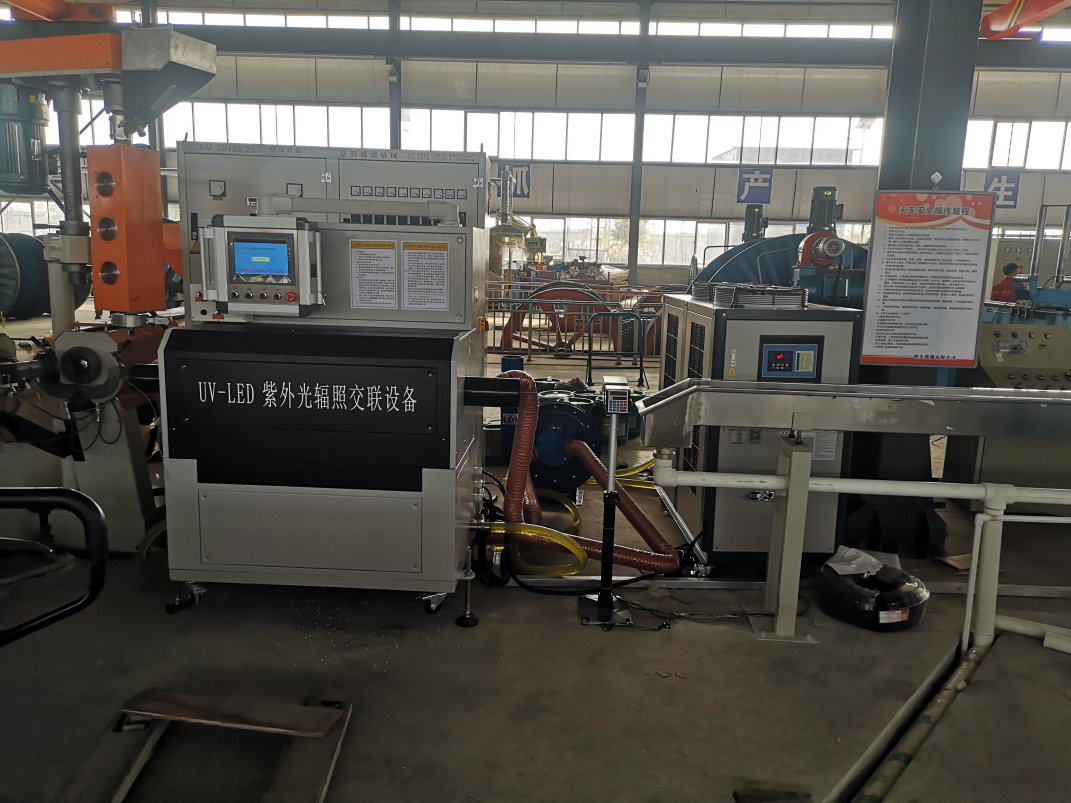

In-site installation of LED ultraviolet irradiation cross-linking machine