FYTY Series Setšoantšo se Methang se Bohlale

Tlhaloso ea Sehlahisoa

Kopana le maemo: IEC60811,TB2809-2017,GB/T2951

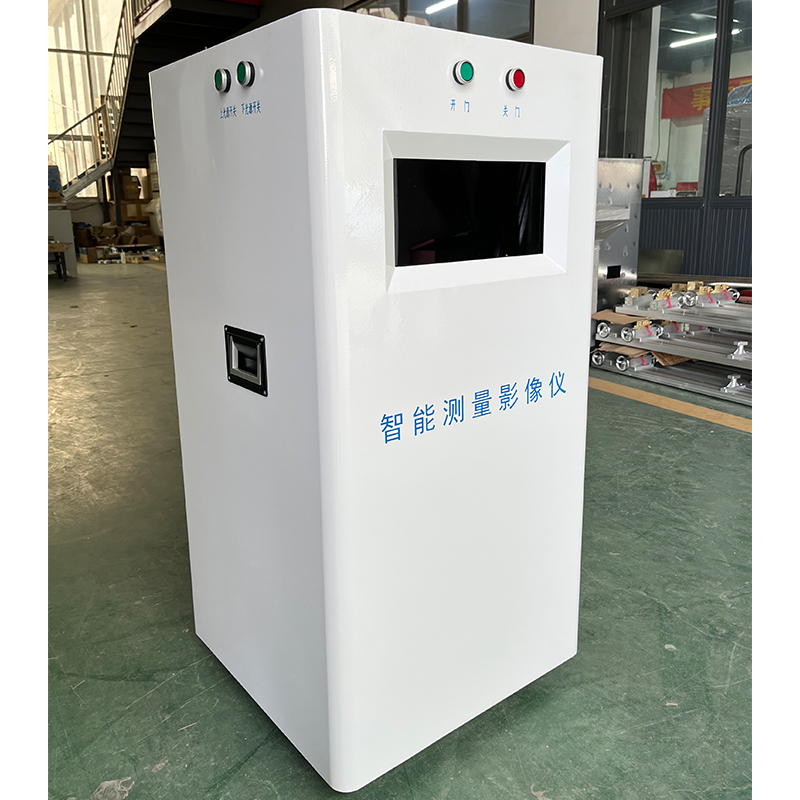

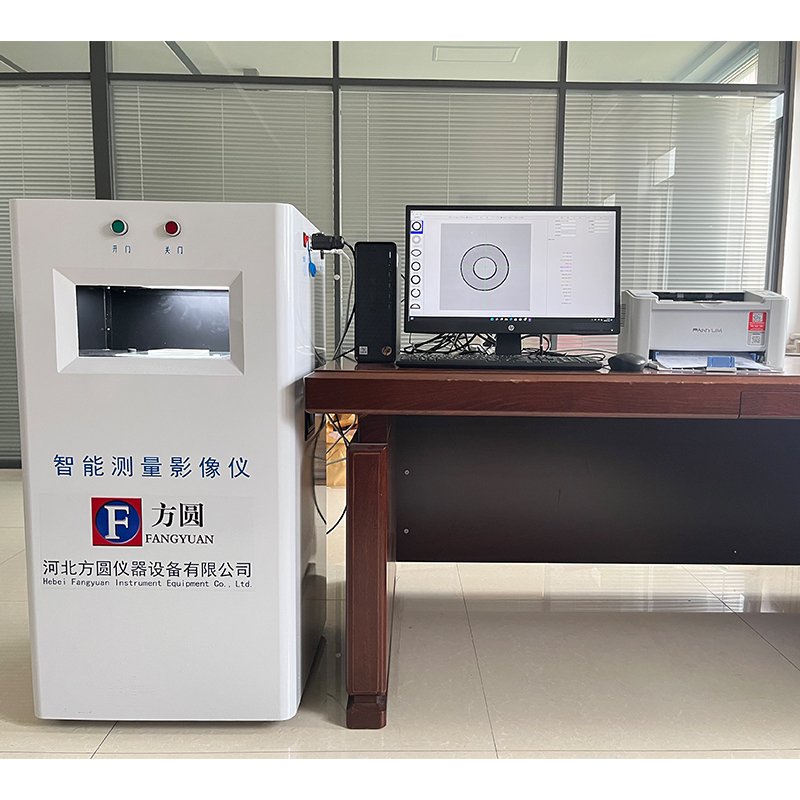

The intelligent measuring imager is an independently developed measuring system that uses visual inspection methods to measure the structure data of wires and cables. The product is designed and manufactured in accordance with the measurement requirements of the thickness and dimensions of the IEC 60811-1-1(2001)/GB/T2951.11-2008/TB2809-2017 (the implementation standard for locomotive contact wires)standards.

Ka ho kopanya pono ea mochine le theknoloji ea ho sebetsana le litšoantšo tsa k'homphieutha, sehlahisoa sena se khona ho lemoha ka potlako le ka nepo botenya, bophara ba ka ntle, eccentricity, concentricity, ellipticity le litekanyo tse ling tsa ho kenya letsoho le sheath ea mefuta e mengata ea lithapo le likhoele tse boletsoeng ho standard, le hape lekanya boleng ba sebaka sa cross-sectional sa lera le conductor ka 'ngoe. Ho nepahala ha tekanyo ea sesebelisoa ho molemo haholo ho feta ho nepahala ho hlokoang ke maemo.

Mesebetsi le Likarolo

Using computer vision technology, inspection is rapid and timely, far exceeding the measurement speed of manual projectors and reading microscopes. Automatic inspection of the structural parameters of the cable according to the inspection shape selected by the user enables more accurate inspection accuracy than manual measurement and the measurement specifications required by IEC 60811-1-1 (2001). Use LED parallel light sources to improve lighting uniformity and life to ensure continuous and stable light. Fast measurement data can quickly guide product production, ensure product quality, and can reduce the cost of cable production materials, reduce the error rate of human measurement and improve measuring efficiency.

Boloka tlaleho ea maemo a morao-rao a IEC a terata le lithapo le mekhoa ea liteko ka nako. Lintlafatso tsa mananeo a mahala li fanoa ho basebelisi, 'me sebopeho sa' mele se entsoeng ka botsebi se netefatsa litekanyo tse utloahalang le tse tšepahalang. Ho sebelisa liindasteri tsa boemo bo holimo lik'hamera tsa digital tse nang le 10 megapixel (1-80mm) le 20 megapixel (80-140mm) CMOS sensors lihlopha tse 'nè tse fapaneng tsa lik'hamera li khona ho lemoha mefuta e sa tšoaneng ea terata le lithapo le data ea boholo ba sheath ho tloha bophara ba 1mm ho isa ho 140mm bophara.

Tlhophiso

CCD le lense tse nepahetseng haholo li sebelisoa e le lisebelisoa tsa ho fumana litšoantšo ho etsa litšoantšo le lisampole ho fihlela tlhahlobo e nepahetseng le e tsitsitseng ea liteko le ho ntlafatsa katleho ea liteko.

Tekanyo e sa amaneng le batho, ho lekanya ka mokhoa o ikemetseng le ka mokhoa o nepahetseng ntho e lekiloeng, ka katleho ho qoba ho se tsitse ha tekanyo ea letsoho.

|

Ntho |

Sistimi ea ts'ebetso ea sets'oants'o se bohlale sa ho metha |

|||

|

Litekanyetso tsa liteko |

Botenya, bophara ba kantle le data ea ho lelefatsa ha lisebelisoa le lisebelisoa tsa sheath tsa likhoele le likhoele tsa optical |

|||

|

Mofuta oa mohlala |

Lisebelisoa tsa insulation le sheath bakeng sa likhoele le likhoele tsa optical (elastomers, polyvinyl chloride, polyethylene, polypropylene, jj.) |

|||

|

Lekhalo la ho lekanya |

1-10mm |

10-30 limilimithara |

30-80 limilimithara |

80-140 limilimithara |

|

Khamera |

No.1 |

No.2 |

No.3 |

No.4 |

|

Mofuta oa sensor |

CMOS e tsoelang pele scan |

CMOS e tsoelang pele scan |

CMOS e tsoelang pele scan |

CMOS e tsoelang pele scan |

|

Pixel ea lense |

10 milione |

10 milione |

10 milione |

limilione tse 20 |

|

Qeto ea setšoantšo |

2592*2600 |

2592*2600 |

2704*2700 |

3488*3500 |

|

Qeto ea pontšo |

0.001mm |

|||

|

Tekanyo e pheta-phetoang (mm) |

≤0.002 |

≤0.005 |

≤0.01 |

≤0.03 |

|

Measurement accuracy (μm) |

4+L/100 |

8+L/100 |

20+L/100 |

40+L/100 |

|

Ho fetola lense |

Fetola lense ka bolokolohi |

|||

|

Nako ea teko |

≤10sec |

|||

|

Mokhoa oa teko |

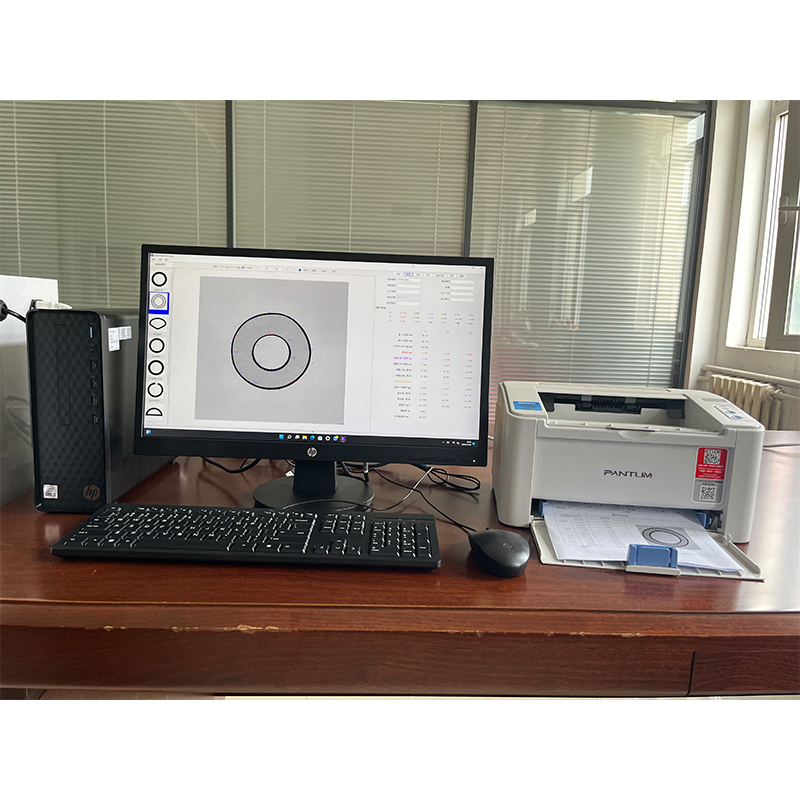

Tekanyo e le 'ngoe ea ho tobetsa, tobetsa konopo ea tekanyo ka mouse, software e tla lekoa ka bo eona, litekanyetso tsohle li tla lekoa ka nako e le' ngoe, tlaleho ea teko e tla ntšoa ka bo eona, 'me data e tla bolokoa ka har'a database ka bo eona.

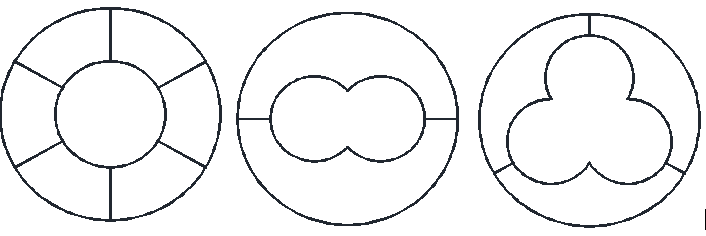

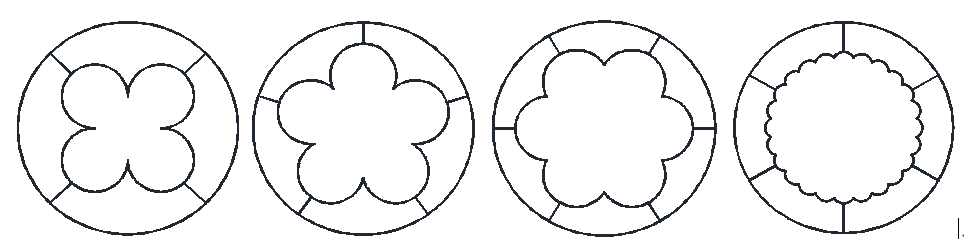

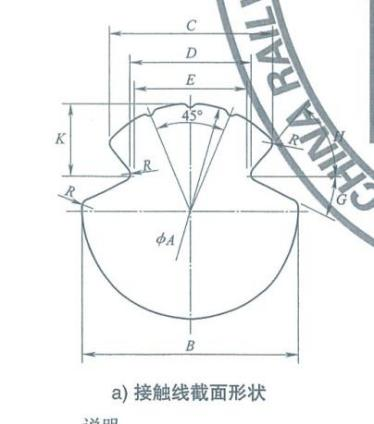

Software ea liteko: 1. Insulation ea cable e lekiloeng le sebopeho sa sheath se kenyelletsa IEC60811. Setšoantšo sa 1 ho isa ho sa 11. ① Tekanyo ea botenya le botenya ba sheath (sebaka se ka hare se chitja) ②Tekanyo ea botenya ba insulation (mokhanni oa sebopeho sa karolo) ③ Tekanyo ea botenya ba insulation ④ Tekanyo ea botenya ba insulation (ka ntle ho sa tloaelehang) ⑤ Tekanyo ea botenya ba insulation (terata e bataletseng e habeli e se nang sheathed) ⑥Tekanyo ea botenya ba Sheath (sebaka se ka hare se sa tloaelehang) ⑦ Tekanyo ea botenya ba Sheath (sebaka se ka hare se seng selikalikoe) ⑧ Tekanyo ea botenya ba Sheath (ka ntle ho sa tloaelehang) ⑨ Tekanyo ea botenya ba Sheath (thapo ea mantlha e bataletseng e nang le sheath) ⑩ Tekanyo ea botenya ba Sheath (cable e sephara e nang le mefuta e mengata) TB2809-2017 (tekanyetso ea phethahatso bakeng sa terata ea khokahanyo ea locomotive) boholo ba karolo le tekanyo ea angle.

2.Tsehetsa teko ea mohala oa sebopeho sa coextrusion se nang le likarolo tse tharo tsa cable e mahareng le e phahameng.

3.Insulation le lintho tsa teko ea sheath Botenya bo boholo, botenya ba bonyane le botenya ba karolelano. Boholo ba bophara, bonyane ba bophara, bophara ba karolelano, sebaka se pota-potileng. Eccentricity, concentricity, ovality (chitja).

4.Conductor reference cross-sectional area

5.Mokhoa oa ho lekanya o entsoe ka boikemelo ho latela litlhoko tsa 3C: kopana le litlhoko tsa 1.9.2 ho GB/ t5023.2-2008: "nka likarolo tse tharo tsa lisampole bakeng sa terata e 'ngoe le e 'ngoe e sirelelitsoeng, lekanya boleng ba karolelano ea boleng ba 18 (e hlalositsoe ho mm), bala ho ea ho libaka tse peli tsa decimal, 'me u pota-potile ho ea ka lipehelo tse latelang (sheba mantsoe a tloaelehileng bakeng sa ho fokotsa melao), ebe u nka boleng bona e le karolelano ea boleng ba botenya ba ho pata." Tlaleho e ikhethang ea 3C e ka hlahisoa, e nang le ts'ebetso ea ho fumana mangolo.

6.Manual measurement function: even if you meet the section shape of wire and cable insulation thickness not listed in the standard, the manual measurement function is added in the software. Just click the position to be measured in the section view, that is, the point-to-point length will be displayed automatically. After the measurement, the minimum thickness and average thickness of these positions can be displayed automatically。 |

|||

|

Tshebetso ya ho lekanya |

Ho fanoe ka boto e tloaelehileng ea ring calibration, e ka sebelisoang bakeng sa ho lekanya lisebelisoa |

|||

|

Mohloli oa leseli oa bophelo bo bolelele |

Mohloli o phahameng oa khanya ea LED e tsamaisanang le khanya, leseli la monochromatic, fokotsa ho hasana le ho totobatsa mokoloko oa ntho e lekantsoeng ka tekanyo e kholo ka ho fetisisa. Moralo o ikhethileng oa 90 degree angle axiliary cross light source e ka lekanya lisampole tse opaque. |

|||

|

Sistimi ea tsela e bobebe |

Chassis e tiisitsoeng ka ho feletseng, e sebelisa mokhoa oa ho thibela lerōle o otlolohileng ho fokotsa refraction ea optical. |

|||

|

Kamore e khanyang ea ho lekanya |

Kamore ea mabone a matšo e fokotsa khanya e pharalletseng, e tlosa tšitiso ea mabone a lahlehileng, 'me e qoba liphoso tsa data tse fosahetseng. |

|||

Lisebelisoa tsa Mohloli oa Leseli

|

Ntho |

Mofuta |

Mmala |

Leseli |

|

Lebone la morao le tšoanang |

LED |

Bosoeu |

9000-11000LUX |

|

2 tšela mehloli e thusang ea mabone |

LED |

Bosoeu |

9000-11000LUX |

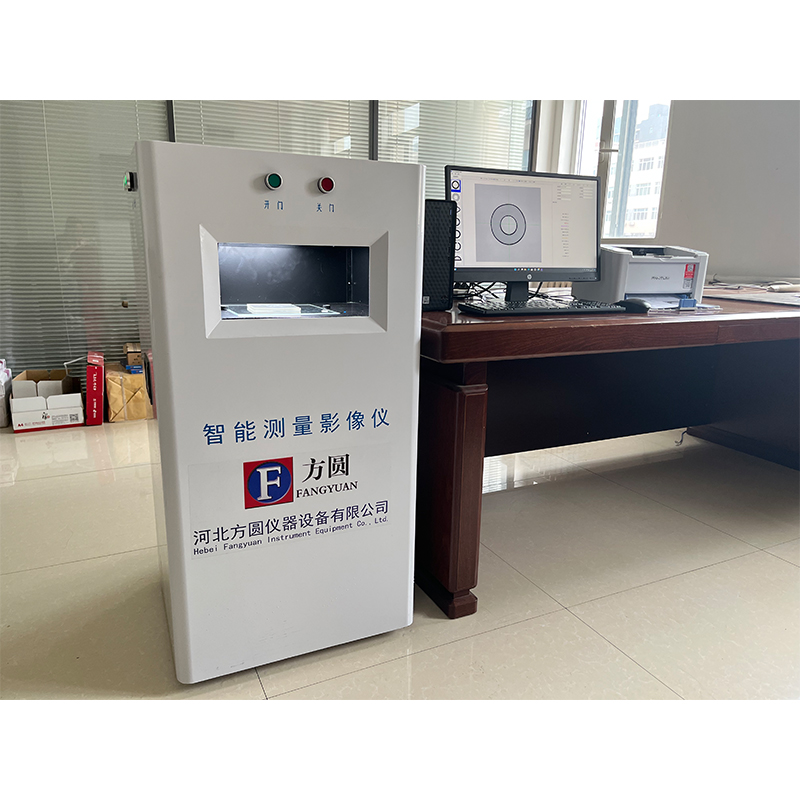

Khomphuta

Processor Intel G6400, quad-core, 4.0GHz, 4G memory, 1TG hard drive, 21.5-inch display, operating system window10

Mohatisi

Mohatisi oa laser, pampiri ea A4, khatiso e ntšo le e tšoeu

Mohlala

Likotoana tse chitja (mefuta e 7)

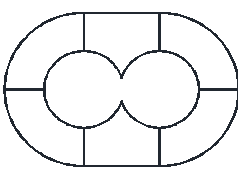

Regular ring Double-core round Three-core round

Four-core round Five-core round Six-core round Irregular ring

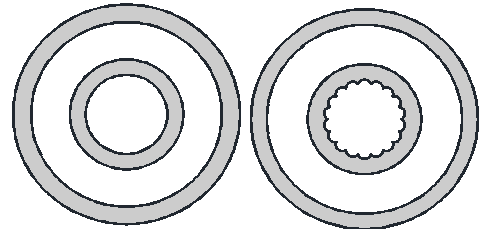

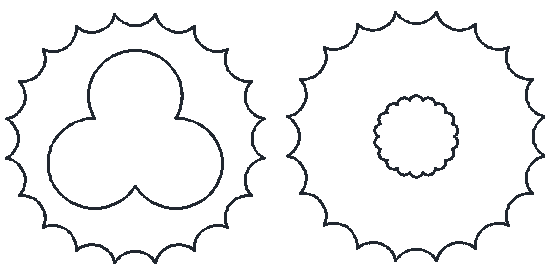

selikalikoe sa mekhahlelo e meraro (mefuta e 2)

Tlhaloso: Lesale la ka hare le boreleli le lesale la ka hare la burr

Smooth inner ring Internal burr ring

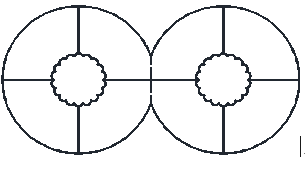

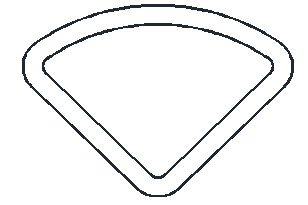

Telescope (mofuta o le mong)

Lekala (mofuta o le mong)

Double core flat (mofuta o le mong)

Potoloho e sa tloaelehang (mefuta e 2)

Single-layer three-core irregular circles Single-layer irregular circles inside and outside

TB2809-2017 (Maemo a Phethahatso bakeng sa Tekanyo ea Khokahano ea Locomotive) Maemo a Karolo le Methatso ea Angle

Tekanyo ea thapo ea ho kenya letsoho ea thapo e opaque e habeli kapa e nang le rabara e nang le rabara e nang le matla a phahameng a matla.

Sebelisa Maemo a Tikoloho

|

Che. |

Ntho |

Yuniti |

Boleng ba projeke bo hlokahalang |

||

|

1 |

Mocheso oa tikoloho |

Boholo ba mocheso oa letsatsi le letsatsi |

℃ |

+40 |

|

|

Mocheso o fokolang oa letsatsi le letsatsi |

-10 |

||||

|

Phapang e kholo ea mocheso oa letsatsi le letsatsi |

℃ |

30 |

|||

|

2 |

Bophahamo |

M |

≤2000 |

||

|

3 |

Mongobo o amanang |

Mongobo o lekanyelitsoeng oa letsatsi le letsatsi |

|

95 |

|

|

Mongobo o moholo o lekanyelitsoeng oa khoeli le khoeli |

90 |

||||

Tokiso ea mochini

|

Ntho |

Mohlala |

Qty |

Yuniti |

|

|

Sets'oants'o se bohlale sa ho metha |

FYTY-60 |

1 |

Beha |

|

|

1 |

Mochini |

|

1 |

Beha |

|

2 |

Khomphuta |

|

1 |

Beha |

|

3 |

Mohatisi oa laser |

|

1 |

Beha |

|

4 |

Calibration board |

|

1 |

Beha |

|

5 |

Khalase e hatisitsoeng |

150*150 |

1 |

Sekhechana |

|

6 |

Cable ea data ea USB |

|

1 |

Sekhechana |

|

7 |

Software |

|

1 |

Beha |

|

8 |

Litaelo tsa Ts'ebetso |

|

1 |

Beha |