Lisebelisoa tsa LED tsa Ultraviolet Irradiation Polyolefin Crosslinking

Tlhaloso ea Sehlahisoa

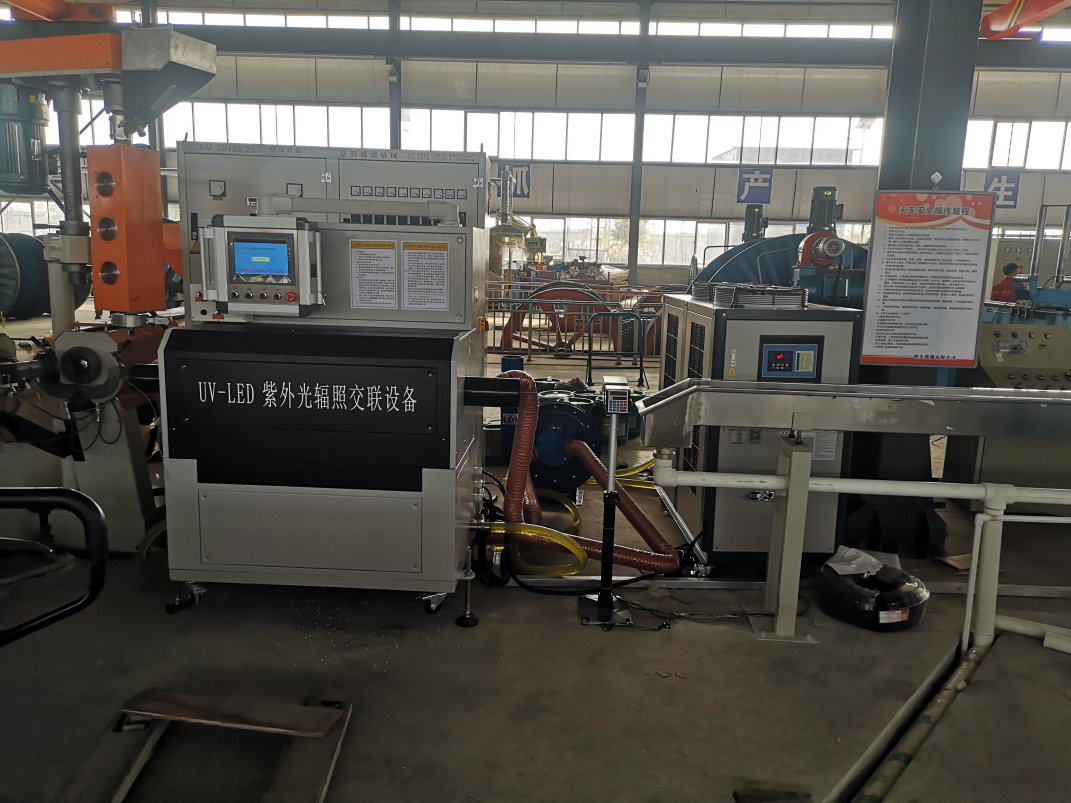

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

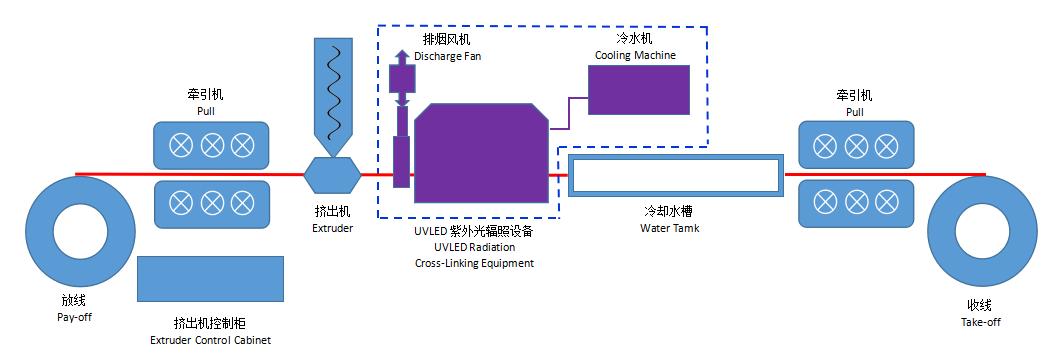

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Litšobotsi

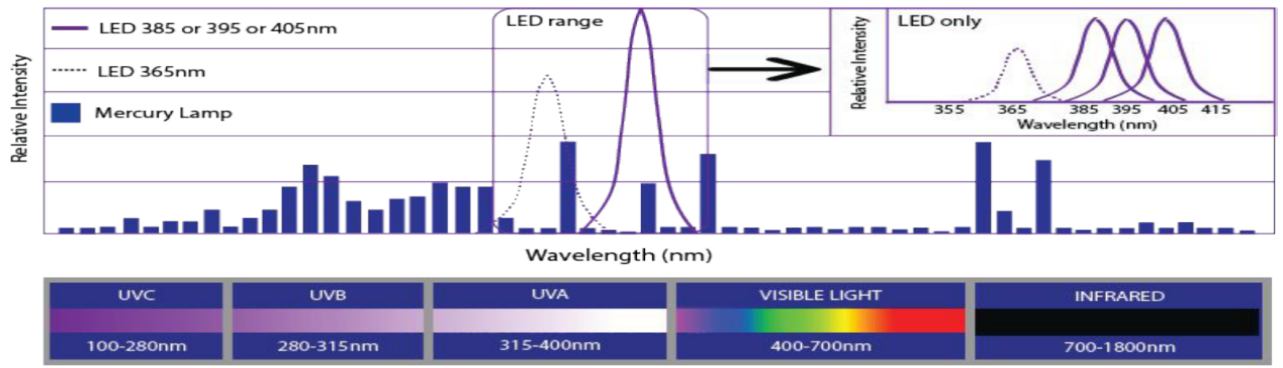

Sesebelisoa sa Ultraviolet LED ke mohloli o tsoetseng pele ka ho fetesisa oa mahlaseli a ultraviolet lefatšeng, o nang le matla a phahameng a matla (hoo e ka bang 30%), khetho e phahameng haholo ea maqhubu a matla (half-power wavelength bandwidth 5nm), bophelo ba ts'ebeletso e phahameng haholo (lihora tse 30,000), mocheso o tlase oa infrared. moloko, ha ho na moloko oa ozone, o loketseng haholoanyane bakeng sa phekolo ea cross-linking ea polyolefin e amanang le sefapano le lisebelisoa tse ling.

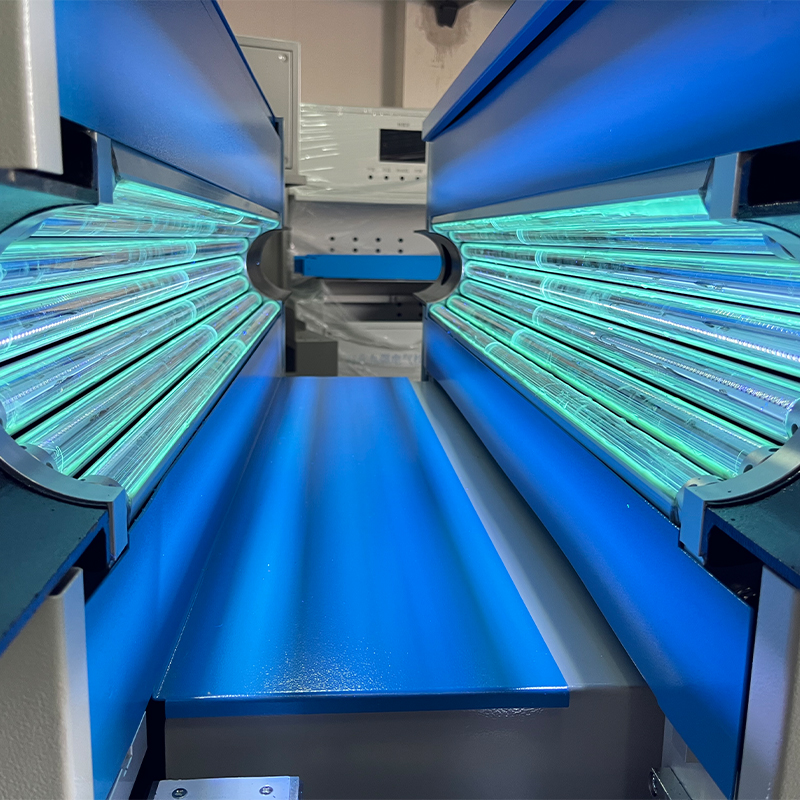

Mohloli oa UV LED o sebelisa sebopeho sa lense se nang le tokelo ea molao ho bonesa bokaholimo ba thapo ka ho lekana le ka mokhoa o ts'oanang. Moralo oa substrate o etsoa ka motsoako oa Fluent software simulation fluid le LED junction teko ea mocheso, 'me boto ea potoloho ea LED e entsoe ka motsoako oa aluminium nitride ceramic le base ea koporo e nang le ts'ebetso e ntle ea ho qhala mocheso,' me e na le mokhoa o sebetsang haholoanyane oa ho qhala mocheso. tsamaiso.

Mohloli oa UV LED o sebelisa mohloli oa matla a marang-rang a abuoang ho khanna UV LED. Phepelo ea motlakase e tsamaisoang e kentsoe tšebetsong ea "vacuum potting" ho netefatsa ho ts'epahala ha phepelo ea motlakase. Ka nako e ts'oanang, sebopeho sa motlakase oa ho khanna se nka mokhoa o moqotetsane le o molelele, 'me mohloli oa leseli la LED oa nako e telele o nka mokhoa oa ho kenya ka morao-morao bakeng sa potoloho ea LED ho fokotsa bolelele ba terata. Tseba hore mohloli oa leseli o butse, oa tima, 'me oa fifala.

Thepa ea UV LED irradiation polyolefin cross-linking e nka sebopeho sa kotopo ea selikalikoe, 'me e na le mohloli o khanyang oa lebone la ultraviolet ho theha kotopo bakeng sa ho khantša sebaka se bohareng,' me matla a sesebelisoa a ka behoa ka mokhoa o sa tsitsang ka har'a mefuta e 10. ho isa ho 100%.

Ha ho bapisoa le lisebelisoa tsa khale tsa mofuta oa lebone la mercury (lebone la setso le tsamaisoang ke UVI/UVII le UVE-I e khannoang ke motlakase oa elektroniki), khokahano ea li-electron accelerator le silane cross-linking, e na le melemo e latelang:

1 Tšebeliso e tlase ea Matla

UV LED irradiation polyolefin cross-linking lisebelisoa tse kentsoeng matla a lekana le 1/4 ea lisebelisoa tsa mantlha tsa mahlaseli a ultraviolet, 1/30 ea accelerator ea elektronike, mouoane oa metsi kapa oa metsi o hloka ho futhumatsoa ha nako e telele, 'me tšebeliso ea matla ea metsi a futhumatsang e ngata haholo. hodimo.

2 Nako e Khutšoane

Khokahano ea sefapano e sebelisa mokhoa oa marang-rang oa extrusion cross-linking ho fokotsa ts'ebetso e latelang ea ho hokahanya ha li-cross-link, ha e bapisoa le nako e hlokahalang bakeng sa ho hokela silane e phehiloeng kapa e thusitsoeng ka mouoane le ts'ebetso ea ho sebetsa ha mahlaseli a elektronike, ho boloka terata le nako ea tlhahiso ea cable. , haholo-holo tšohanyetso Ho phethoa ha thomo, melemo ke ea bohlokoa.

3 Theko e tlaase

Ha ho bapisoa le metsi a futhumetseng a hokahanyang le ho sebetsa ka matla a electron beam, theko ea thapo ea mahlaseli a kotsi a ultraviolet e tlaase, 'me mekhoa e mengata e rarahaneng e fokotsehile ts'ebetsong ea tlhahiso, joalo ka litšenyehelo tsa lipalangoang tsa lithapo tse felileng le litšenyehelo tse tsamaellanang tsa opareitara.

4 Ha ho na ozone

Khetho e phahameng haholo ea wavelength, e ntša feela maqhubu a bohlokoa, ha ho mahlaseli a infrared, boleng bo tlaase ba calorific; palo e tlaase haholo ea mahlaseli a bonahalang, ha ho na tšilafalo ea leseli; ha ho mahlaseli a ultraviolet a maqhubu a makhutšoane, ha ho kotsi 'meleng oa motho, tlhahiso ea ozone ea zero. Ha ho na tlhoko ea ho pholisa moea o matla haholo, ha ho hlokahale hore ho be le duct e rarahaneng ea ho ntša mocheso le moea o ntšang ozone, ho hlokahala feela ho hokela phala e nyane ea bophara bo nyane le fan ea 2kW ho qhelela ka thoko mosi oa limolek'hule tse tlase tse hlahisoang nakong ea insulation extrusion. . Thibela liphello tsa khanya ea mahlaseli.

5 Small Size, Ho bonolo ho e kenya

Kenya feela sebaka se ka bang 2m pakeng tsa mochini oa pele oa tlhahiso ea extruder hlobo le tanka ea metsi a futhumetseng, 'me u behe mochine oa mahlaseli sebakeng sa limithara tse 2.5 ~ 3 ka bophara, kapa se fokolang. The chiller ka behoa sebakeng seo.

6 Ho Bonolo ho Sebetsa

Mohaho o khutsitseng oa ho bula le ho koala kotopo, ho bonolo ho hloekisa le ho roala melapo, ho bonolo ho sebetsa, ha ho na ts'ebetso e rarahaneng, e ka phethoang ke opareitara ea extruder.

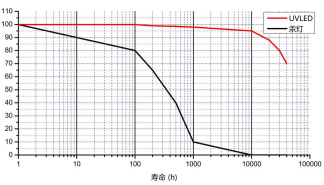

7 Nako e telele ea bophelo le litšenyehelo tse tlase tsa tlhokomelo

Bophelo ba lisebelisoa tsa LED ke lihora tse ka bang 30,000, 'me bophelo ba lisebelisoa tse ling tsa motlakase le tsa elektronike ha bo tlase ho feta bophelo ba lihlahisoa tse tloaelehileng tsa motlakase le tsa elektronike, ntle le ho hlokomeloa khafetsa. Tlhokomelo ea kamehla ho boloka lense ea optical e hloekile, lintho tse sebelisoang ke li-wipe tsa indasteri le li-soot cleaners, tse ka etsoang ke opareitara. Lisebelisoa tse tloaelehileng tsa mabone a mabone ke mabone a UV le li-reflectors, tse hlokang ho nkeloa sebaka ka nako e khuts'oane. Setsi sa mahlaseli a mahlaseli a elektronike se boetse se hlokahala ho boloka sehlopha sa tlhokomelo.

8 Botala

The Ambient Air Quality Standard (GB3095-2012) ho Industrial Hygiene Standard e bolela hore maemo a polokeho ea ozone ke 0.15ppm. Thepa e kopanyang UVLED UV e ke ke ea hlahisa ozone, athe lisebelisoa tsa lebone tsa khale tsa mercury li tla hlahisa ozone e ngata. Ozone ke khase e kotsi.

1) Mefuta e mengata ea lisebelisoa

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) Theko e tlaase

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Ho bonolo ho kenya

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) Ho tšepahala ho phahameng

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Papiso ea melemo ea maqhama a macha a marang-rang a LED le marang-rang a silane:

|

Lehlaseli la ultraviolet la LED thepa |

Silane crosslinking thepa |

Ho boloka litšenyehelo |

|

|

Litšenyehelo tsa thepa |

Lik'hilograma tse 600 tsa litšila ka li-extruders tse 90 ka selemo |

Lithane tse 12 tsa litšila ka li-extruder tse 90 ka selemo |

Annual cost savings of 17000 USD per machine per 90 machines |

|

Matla a extruder |

The viscosity ea thepa e nyenyane, tšebeliso ea matla e nyenyane, 'me extrusion ea 90 extruder e ka bang 30KW feela ka lebelo le feletseng. |

Viscosity e phahameng ea thepa, tšebeliso e phahameng ea matla, 90 KW extrusion e felletseng ea lebelo e hlokahalang |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Bili ea motlakase ea maiketsetso |

Ha ho hlokahale ho hloekisa extruder |

Hloekisa extruder ka halofo ea hora letsatsi le leng le le leng |

Boloka 3400 USD ka selemo |

|

Litšenyehelo tsa ho kopanya |

Ho nka mohlala oa lisekoere-mithara tse 35, theko ea motlakase ke 80KW bakeng sa limithara tse 30,000. |

Ho nka mohlala oa lisekoere-mithara tse 35, ho nka lihora tse 4 bakeng sa limithara tse 30,000 tsa marang-rang a mouoane, 'me ho hloka 200KW ea motlakase. |

Save about 7000 USD in electricity every year |

|

Tlhahiso |

Ka nako e le 'ngoe ho hokahanya le extruder, sekontiri sa extrusion se kenngoa ka ho toba ntle le ts'ebetso ea bobeli |

E phehiloe kapa e phehiloe bonyane lihora tse 4 (e hloka sebaka se khethehileng, jenereithara ea mouoane) |

Save 8400 USD per year |

|

Boleng ba sehlahisoa |

Ho fokotseha ha mocheso ka tlase ho 4%, ha ho na gel ea pele, bokaholimo bo boreleli |

Mocheso o matla o honyelehang, ho koala likaroloana tse nyane hangata ho na le bokaholimo bo seng boreleli le gel. |

|

|

Matsete a thepa |

Mahareng |

Tlase (kamore ea mouoane kapa letamo le futhumetseng) |

|

|

Tšebeliso ea matla |

Tlase (e hloka 10 KW feela) |

E phahame (e hloka ho futhumatsa nako e telele) |

|

|

Litsenyehelo tsa tlhahiso |

Tlase |

Phahameng |

|

|

Potoloho ea tlhahiso |

Khutšoane (ho kopanya marang-rang) |

Nako e telele (e hloka ts'ebetso ea bobeli) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Papiso ea melemo ea lebone le lecha la LED le khokahano ea inthanete le lebone la khale la khatello e phahameng ea mercury:

|

Mochini oa mahlaseli a kotsi a LED |

Mochini oa khale oa khatello e phahameng ea mercury lebone la mabone |

|

|

Tšebeliso ea matla |

Karolelano e ka tlase ho 15 kW ka hora |

80KW ka hora |

|

Litsenyehelo tsa ho hlokomela |

Tlase |

Phahameng |

|

Lebelo la tlhahiso |

Phahameng |

Tlase |

|

Bophelo ba lebone |

30000 lihora |

Lihora tse 400 |

|

Lintho tse ka sebelisoang |

Che |

Lebone, setšoantšo, capacitor |

|

Tlhahiso |

Extruder ha e felle ka lebelo le phahameng mme e ka hlahisoa ka ho khantša leseli. |

Lebelo le liehang la tlhahiso, ts'ebetso e tlase, tšenyo ea mosebetsi, ho hlokahala ho futhumatsa halofo ea hora esale pele |

|

Sebaka sa ts'ebetso le fatše |

Ts'ebetso e bonolo, mehato e nyane, ha ho ho ema |

Ts'ebetso e rarahaneng le sebaka se seholo sa fatše |

|

Mochini o mocha oa mahlaseli a LED o boloka litšenyehelo tsa motlakase tsa 34,000 USD.17,000 USD ea basebetsi le lisebelisoa tsa 8,400 USD ka selemo ho feta mochine oa khale oa khatello ea lebone la mercury. |

||

LED le mercury lebone spectral phapang

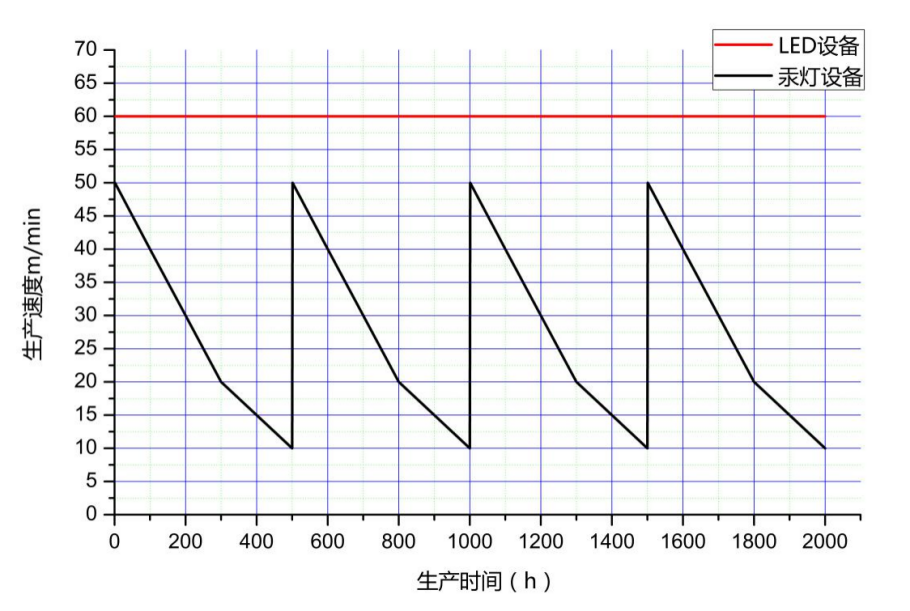

Papiso ea bophelo ba lebone la LED le mercury

Papiso ea lebelo la tlhahiso lipakeng tsa lisebelisoa tsa mabone a mercury le lisebelisoa tsa mabone a LED.

Lisebelisoa tsa Ts'ebetso ea UV-LED Iradiation Crosslinking Performance:

- 1. Matla: tsamaiso ea terata e meraro ea mekhahlelo e mehlano (380V + N + fatše)

- 2. Kakaretso ea matla a mochine o kentsoeng: 20kW

- 3. Sebaka se setle ka ho fetisisa sa sebaka sa mahlaseli: 30mm

4. Bolelele bo sebetsang ba mahlaseli: 1m

- 5. Lifaha tsa lebone li sebelisa mohloli o ka holimo oa lefats'e oa leseli o tsoang linaheng tse ling, lense e sebelisa quartz e tsoang linaheng tse ling, e le hore e be le tahlehelo e fokolang ea matla, lebone la lebone le sebelisa theknoloji ea ho pholisa metsi, e le hore mohloli oa leseli la LED o be le bophelo bo bolelele ba tšebeletso.

- 6. Motlakase o amohela matla a Taiwan Mingwei a sa keneleng metsi, a sirelelitsoeng ke theknoloji ea vacuum potting, e nang le ts'ireletso e feteletseng, potoloho e khutšoanyane, ho feta hona joale, ho feta motlakase le ho sireletsa mocheso.

7. Matla a matla a optical a ka fetoloa ka mokhoa o ikemetseng ho tloha 10% -100%, ho latela litlhoko tsa bareki ho fetola matla leha e le afe.

- 7. Bophelo ba mohloli oa leseli: Lihora tsa 30,000 (tse fanoeng ke moetsi) Matla a khanya a hlahisoang a fokotsehile ho 70% (katleho e theohela ho 70%). Nako ea tšebeliso ke lihora tse 30,000, 'me nako ea ho bala ke lilemo tse 6 ~ 10.

9. Boholo ba lebokose la mahlaseli: 1660mm * 960mm * 1730mm (bolelele x bophara x bophahamo)

Likarolo tsa sebopeho sa lisebelisoa:

- 1. Sebopeho se khutsitseng sa ho bula le ho koala kotopo, ho sebetsa habonolo le ho hloekisa;

- 2. Ho sebelisa segokanyimmediamentsi se bohlale sa ho ama motho, data ea ho beha leihlo, le litlhophiso tsa matla a konopo ea ts'ebetso kaofela li phethiloe ho sebopeho sa skrineng sa ho ama;

- 3. Ts'ebetso ea taolo ea "touchscreen" mme konopo e qala ho phelisana ka thoko;

- 4. Mokhoa oa ho pholile o pholile ka chiller, 'me mokhoa oa ho potoloha o entsoe ka antifreeze e khethehileng bakeng sa likoloi;

- 5. Mokhoa oa ho ntša mosi oa ka ntle, o ntšitsoeng ka kotopo ea moea ka ntle

Sebopeho sa lisebelisoa

Lebelo la tlhahiso ea li-cross-linked polyethylene irradiated material

|

Sebaka sa 1

|

Zone 2

|

Sebaka sa 3

|

Sebaka sa 4

|

Zone 5

|

Hlooho ea mochini |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

Insulation nominal thickness(mm)

|

Lebelo la tlhaho la tlhahiso(m/min)

|

Katoloso ea mocheso (%)

|

Phetoho e sa feleng |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Lebelo le tlase la tlhahiso ea lisebelisoa tsa mahlaseli a halogen a se nang mosi o tlase

|

Sebaka sa 1

|

Zone 2

|

Sebaka sa 3

|

Sebaka sa 4

|

Zone 5

|

Hlooho ea mochini |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

Insulation nominal thickness(mm)

|

Lebelo la tlhaho la tlhahiso(m/min)

|

Katoloso ea mocheso (%)

|

Phetoho e sa feleng |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Lintlha: Hobane lisebelisoa tsa extrusion le ts'ebetso ea tlhahiso le lisebelisoa tsa cable tsa likhoebo tse fapaneng li fapane, lebelo la extrusion le tla fapana. The 90 extruder ha e na moeli.

Ho kengoa setšeng mochini oa marang-rang a marang-rang a LED a ultraviolet