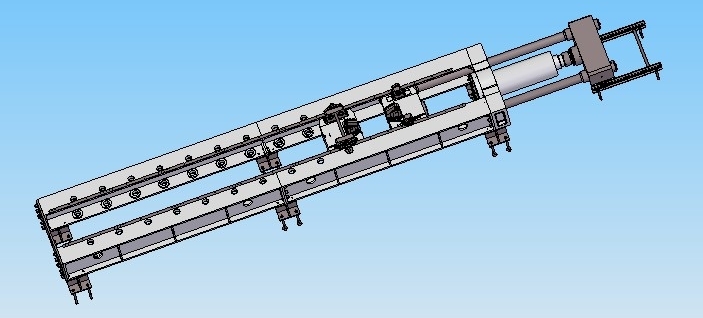

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Tlhaloso ea Sehlahisoa

TXWL-600 electro-hydraulic servo horizontal tensile test mochini o amohela sebopeho sa foreimi e otlolohileng, molamu o le mong o sebetsang habeli oa piston o fana ka matla a teko, mme sistimi ea taolo ea komporo e hlokomela taolo ea othomathi ea tlhahlobo ka ho laola servo valve le likarolo tse ling, tlhahlobo. data e bokelloa ka nepo ke sensor ea mojaro mme e fetisetsoa khomphuteng, sistimi e itlhahloba, e sebetsa le ho boloka liphetho tsa liteko, mme mohatisi a ka hatisa ka kotloloho tlaleho e hlokahalang ea tlhahlobo. Mochine ona o sebelisoa haholo-holo bakeng sa teko e tsitsitseng ea thapo ea tšepe ea tšepe, ke tlhahiso ea morao-rao ea lipatlisiso tsa saense le thuto le liindasteri tse ling ho finyella litlhoko tsa lisebelisoa tse loketseng tsa teko.

Tlhaloso ea Mochini

1.Sistimi ea moamoheli

Karolo e kholo ea mochini e entsoe haholo ka foreimi ea mochini o ka sehloohong, setulo sa silindara ea oli, silinda ea oli, lebone le tsamaeang, setulo sa chuck se ka pele le se ka morao le sensor ea mojaro. E ka etsa liteko tse thata ka boima bo boholo ba 600kN sampole.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Sebaka sa teko se na le sekoahelo se sireletsang, se ka sireletsang ka katleho polokeho ea basebetsi ba liteko.

2.Mohloli oa mohloli oa oli

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Karolo ea Motlakase

Taolo ea motlakase e hlophisitsoe sebakeng sa ts'ebetso ea liteko, 'me ho na le phanele ea ts'ebetso e etselitsoeng ka ho khetheha ho etsa hore mefuta eohle ea ts'ebetso e hlake ha u habanya feela. Likarolo tsa motlakase ke tsa brand ea machaba e tummeng, e nang le ts'ebetso e tsitsitseng le boleng bo ka tšeptjoang.

Software System:

(1) Ho ipapisitsoe le sethala sa ts'ebetso sa Windows XP se nang le mesebetsi e ka lokisoang, taolo ea matla a leka-lekaneng, taolo ea phallo e lekanang, ho ts'oara matla a liteko, ho ts'oara phalliso le mekhoa e meng ea liteko li ka kopanngoa ka boithatelo ho fihlela litlhoko tsa mekhoa e fapaneng ea liteko. ho isa tekanyong e kholo, le ho hlokomela ponts'o e fapaneng ea data, ho taka curve, ts'ebetso ea data, polokelo le mesebetsi ea khatiso e hlokahalang bakeng sa tlhahlobo.

(2) Romela lets'oao la taolo ho valve ea servo ka komporo ho laola ho buloa le tataiso ea valve ea servo, ka hona ho laola phallo ho cylinder, le ho hlokomela taolo ea matla a lekanang a teko, phallo e lekanang, joalo-joalo. .

(3) E na le li-loops tse peli tse koetsoeng tsa taolo ea matla a teko le ho falla.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Khokahano e kholo e na le mesebetsi eohle ea ts'ebetso ea letsatsi le letsatsi ea tlhahlobo, joalo ka ho kenya tlhaiso-leseling ea mohlala, khetho ea sampole, setšoantšo sa curve, ponts'o ea data, ts'ebetso ea data, tlhahlobo ea data, ts'ebetso ea liteko, joalo-joalo. ka potlako.

(6) Lintlha li ka hlahisoa ho mochine oa khatiso ho hatisa tlaleho ea teko.

(7) Tsamaiso ea tsamaiso ea tsamaiso, litekanyetso tsa tsamaiso kaofela li bulehile ho basebelisi ba litsebi, ho netefatsa ho fetoha ha maemo le ho tšepahala ha tsamaiso.

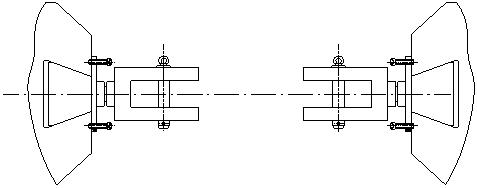

Lisebelisoa tsa 4.Tlhahlobo

E na le lisebelisoa tsa tlhahlobo ea terata (sheba ka tlase) le lisebelisoa tse ling li etsoa ho latela maemo a fanoeng ke mosebelisi kapa litlhoko tsa ho tiea tsa sampole.

5.Lisebelisoa tsa Tšireletso ea Tšireletso

(1) Tšireletso e feteletseng ha matla a teko a feta 2% ho 5% ea matla a mangata a teko kapa boleng bo behiloeng.

(2) Tšireletso ea stroke ha piston e fallela sebakeng se lekanyelitsoeng.

(3) Ka mocheso oa oli, boemo ba mokelikeli le tšireletso ea ho hanyetsa oli le lisebelisoa tse bontšang.

(4) Sebaka sa teko se na le sekoahelo se sireletsang ho thibela sampuli ho senya le ho oela.

(5) Ha ho hlaha ts'ohanyetso, tobetsa konopo ea ho emisa ts'ohanyetso khabineteng ea taolo ka kotloloho

Tekheniki Parameter

1.Matla a phahameng a teko: 600kN

2.Tlhahlobo ea tekanyo ea matla a teko: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

Sebaka sa teko ea 4.Tensile (ntle le stroke ea piston): 20mm ~ 12000mm

5.Piston stroke: 1000mm

6.Lebelo le phahameng la ho sebetsa la piston: 100 mm / min

7.Deformation extensometer ho nepahala: 0.01mm

8.Boemo ba mochine o moholo (mm): 16000 (L) x 1300 (W) x 1000 (H) (ntle le sekoahelo se sireletsang)