FYCS-Z Kawat jeung Kabel Bunched Test Ngaduruk Equipment (Mass Flow Controller)

Panjelasan Produk

Cocog pikeun ngevaluasi kamampuan pamasangan nangtung tina kawat anu dibuntel sareng kabel atanapi kabel optik pikeun nyegah panyebaran seuneu nangtung dina kaayaan anu ditangtukeun.

Standar

Sasuai jeung GB18380.31-2022 "Uji durukan kabel dina kaayaan seuneu - Bagian 3: Pamasangan nangtung tina kawat bunched sareng alat uji sumebar vertikal seuneu kabel", sarua jeung IEC60332-3-10:2000.

Dina waktu nu sarua pikeun minuhan sarat tina Table 4 GB / T19666-2019 "Prinsip Umum seuneu Retardant na Refractory Kawat jeung Cable" baku.

GB/T18380.32--2022/IEC60332--3--21: 2015 "Uji durukan kabel listrik sareng kabel optik dina kaayaan seuneu - Bagian 32: Kawat dipasang vertikal sareng kabel seuneu uji sumebar vertikal AF / R kategori".

GB / T18380.33--2022/IEC60332--3--22: 2015 "Uji durukan kabel listrik sareng kabel optik dina kaayaan seuneu - Bagian 33: Kawat dipasang vertikal sareng kabel seuneu tes sumebar vertikal kategori A".

GB/T18380.35--2022/IEC60332--3--24: 2015 "Uji durukan kabel listrik sareng kabel optik dina kaayaan seuneu - Bagian 35: Kawat dipasang vertikal sareng kabel seuneu tes sumebar vertikal kategori C",

GB/T18380.36--2022/IEC60332--3--25: 2015 "Uji durukan kabel listrik sareng kabel optik dina kaayaan seuneu - Bagian 36: Kawat dipasang vertikal sareng kabel seuneu tes sumebar vertikal kategori D".

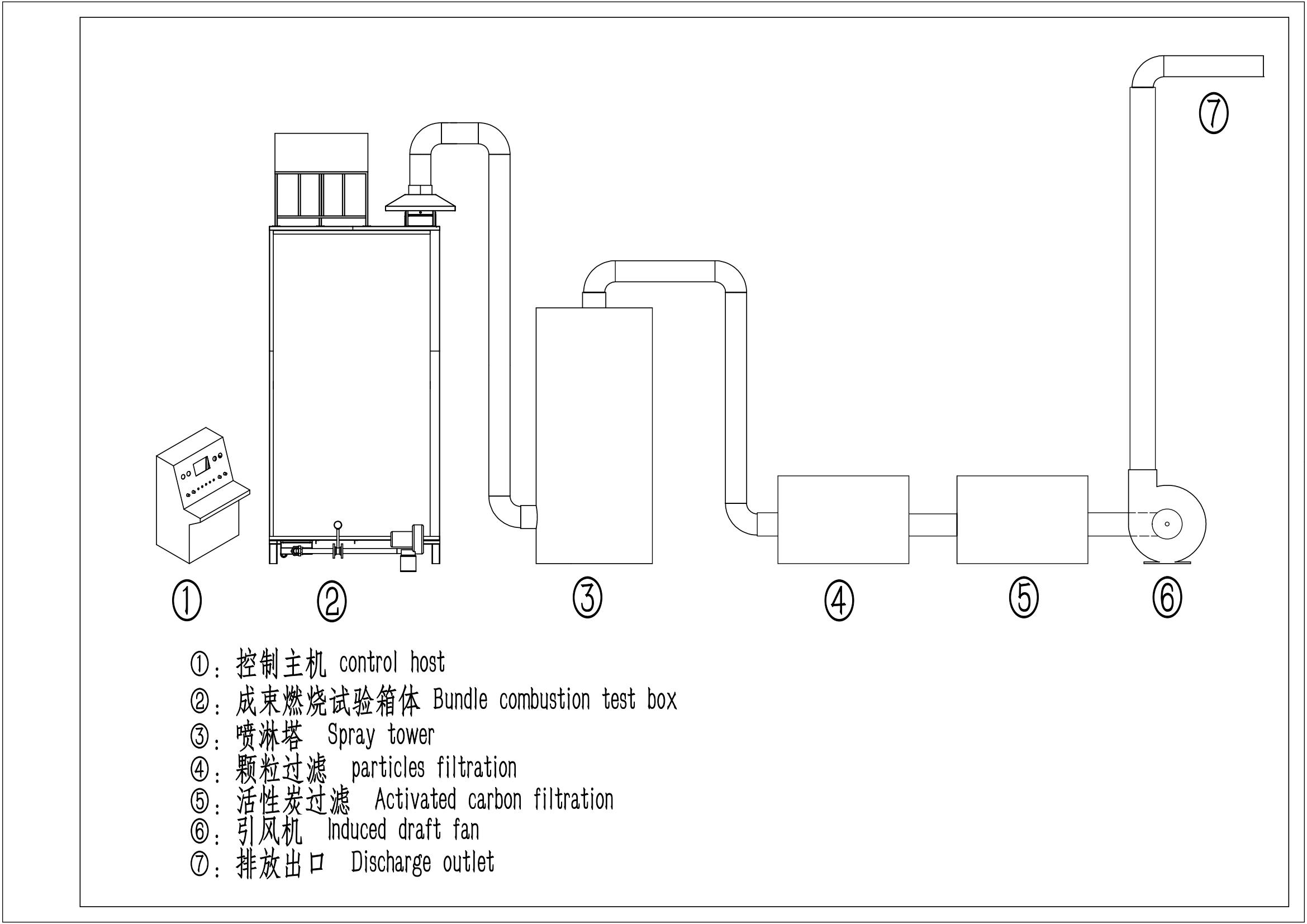

Komposisi Parabot

Kamar uji durukan, sistem kontrol listrik, sumber hawa, sistem kontrol aliran massa sumber ignition (gas propana sareng gas dikomprés hawa), tangga baja, alat pemadam seuneu, alat pemurnian émisi, jsb.

Parameter Téknis

1.Working voltage: AC 220V±10% 50Hz,Power consumption: 2KW

2.The inlet and outlet air flow rate: 5000±200 L/min(adjustable)

Aliran 3.Air sareng aliran propana dikawasa ku sistem kontrol aliran massa.

Sumber 4.Air: propana (0.1Mpa), hawa (0.1Mpa), sumber hawa customer-milik.

5.Timing rentang: 0 ~ 60min (tiasa diatur)

6.Anemometer measurement range: 0 ~ 30m/s, measurement accuracy: ±0.2m/s

7.Test chamber dimensi (mm): 2184 (L) x 1156 (W) x 5213 (H)

Dieusian ku bahan wol batu insulasi tahan seuneu mineral, luhur kalayan guardrail kaamanan tinggi 1500mm.

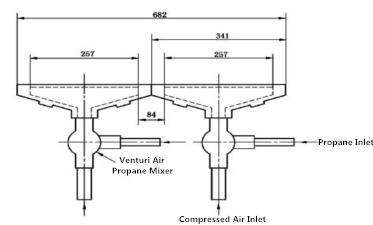

8.2 huluna blowtorch durukan kalawan mixer Venturi

9.The kipas inlet hawa nyaéta kipas vortex low-noise. PLC ngadalikeun laju kipas ngaliwatan konverter frékuénsi, sareng flowmeter vortex ngukur volume hawa pikeun ngahontal kontrol volume inlet hawa anu tepat.

10.The ngainduksi draf kipas adopts 4-72 kipas anti korosi kalawan volume hawa 5000m2/h.

11.Flue gas post-treatment ieu dilengkepan munara panyabutan lebu semprot cai kalawan volume hawa processing 5000 m.2/h

12.Both nitrogén seuneu extinguishing jeung cai semprot métode extinguishing seuneu anu dilengkepan pikeun konsumén milih.

13. Pikeun nguji:

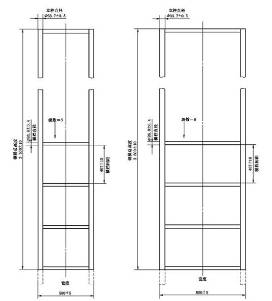

Diménsi tangga baja baku nangtung (mm): 500 (W) x 3500 (H)

Dimensi tangga baja lega vertikal (mm): 800 (W) x 3500 (H)

14. Ukuran permukaan durukan (mm): 257 (L) x 4.5 (W)

15.Touch kontrol layar, intuitif jeung jelas, ignition éléktronik, timing otomatis.

16.The burner ieu dikawasa ku PLC tur dioperasikeun ku layar toél.

Alat Uji

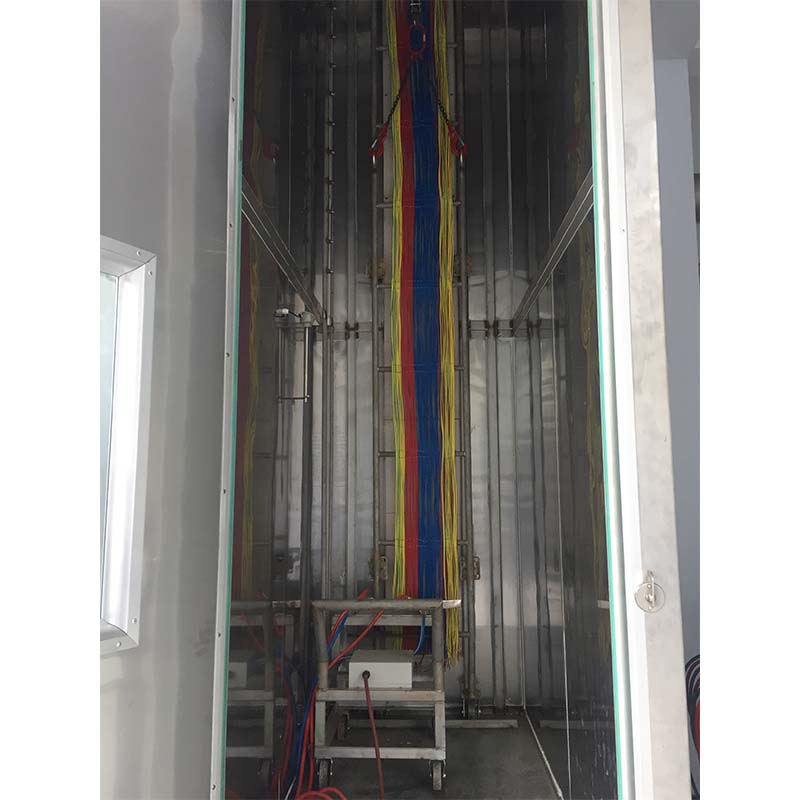

Test box: The experimental device should be a self-standing box with a width of 1000mm, a depth of 2000mm and a height of 4000mm. The bottom of the box should be 300mm above the ground. The perimeter of the test chamber should be sealed, the air from the bottom of the chamber from the front wall (150±10) mm to open a (800±20) mm x (400±10) mm air inlet into the box. A (300±30) mm x (1000±100) mm outlet should be opened at the back of the top of the chamber. Test chamber should be used on both sides of the heat transfer coefficient of about 0.7W.m-2.K-1 thermal insulation, the distance between the steel ladder and the back wall of the test chamber is (150±10) mm, and the bottom rung of the steel ladder is (400±5) mm from the ground. The lowest point of the cable sample is about 100mm from the ground.

-

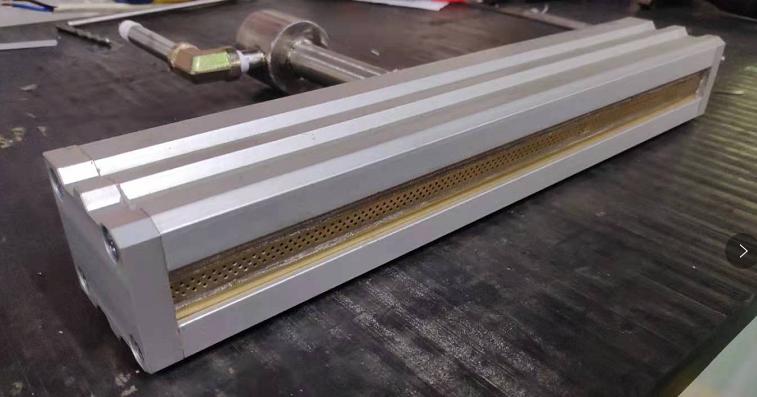

Baku Venturi Blowtorch

-

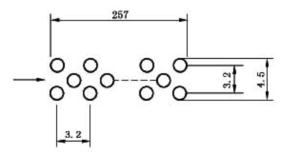

Liang obor

-

Pembakar

-

Adun Venturi

1.Anemometer: ngukur laju angin di luar luhureun chamber test, lamun speed angin ngaleuwihan 8m / s lajeng test teu bisa dilaksanakeun.

2.Temperature usik: dua K-tipe thermocouples anu dilengkepan dina dua sisi tina kotak test, lamun suhu tembok jero leuwih handap 5 ℃ atawa leuwih luhur ti 40 ℃, test teu bisa dilaksanakeun.

3.Air source: adopt touch screen controller, frequency conversion control inlet axial flow fan, can intuitively read out and control the gas flow through the air box for (5000±200) L/min, stable air flow rate during the test.

4.After parantosan test: Lamun sampel masih ngaduruk sanggeus hiji jam stopping seuneu, alat semprot cai atawa alat extinguishing seuneu nitrogén bisa dipaké pikeun forcibly ngeureunkeun seuneu, sarta aya corong husus pikeun meresihan up runtah.

5.Steel ladder type: width (500±5)mm standard steel ladder, width (800±10)mm wide steel ladder, material for SUS304 stainless steel tube.

Masing-masing pikeun tangga baja standar sareng lega

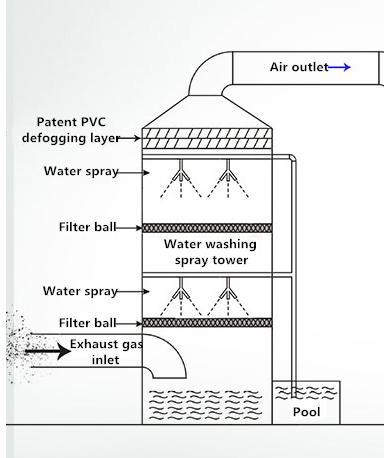

Alat Pemurnian émisi

kempelan haseup jeung ngumbah alat soot: bahan PP, kalayan diaméter 1500mm sarta jangkungna 3500mm. Munara kempelan haseup dibagi kana tilu bagian: alat semprot, haseup jeung alat filter lebu, sarta alat haseup knalpot. Alat semprot: nyadiakeun semprot cai pikeun bahan filter husus, tetep bahan filter husus pikeun nyaring haseup jeung lebu éféktif. Haseup sareng alat saringan lebu: Disaring ku bahan saringan cai nginum, anu sacara efektif tiasa nyaring haseup sareng lebu sahingga haseup anu dipancarkeun nyaéta haseup bodas. Konsumén nambahkeun alat panyalindungan lingkungan nurutkeun kaayaan.

-

Haseup Koléksi Tower Schematic

-

munara ngumpulkeun haseup

-

Ngainduksi draf kipas

Sumber Ignition

1.Ignition source type: including one or two band-type propane gas blowtorches and their matching flowmeters and Venturi mixers. The ignition surface is drilled with 242 flat metal plates with a diameter of 1.32mm. The center distance of these holes is 3.2mm, arranged in three rows in a staggered arrangement, each row is 81, 80 and 81, distributed in the nominal size is 257×4.5mm. In addition, a row of small holes are opened on both sides of the flame board, and this guide hole can maintain the stable combustion of the flame.

2.Ignition source location: The torch should be placed horizontally, (75±5) mm from the front surface of the cable sample, (600±5) mm from the bottom of the test chamber, and symmetrical to the axis of the steel ladder. The flame supply point of the blowtorch should be located in the center between the two crossbeams of the steel ladder, and at least 500mm away from the lower end of the sample. The center line of the blowtorch system should be approximately the same as the center line of the steel ladder.

-

Vortex Aliran Méter pikeun

Kontrol anu tepat tina Volume Udara Inlet -

Vortex kipas inlet hawa

Aliran Massa Controller

Pengontrol aliran massa dianggo pikeun pangukuran anu tepat sareng kontrol aliran massa gas. Méter aliran massa ngagaduhan fitur akurasi anu luhur, kabisaulangan anu saé, réspon gancang, mimiti lemes, stabilitas sareng reliabilitas, rentang tekanan operasi anu lega. Kalayan panyambungna standar internasional, éta gampang pikeun beroperasi sareng dianggo, tiasa dipasang dina posisi naon waé, sareng gampang nyambung sareng komputer pikeun kontrol otomatis.

Parameter téknis kontrol aliran massa:

1.Accuracy: ±2% F.S

2.Linearity:±1% F.S

3.Repeat accuracy:±0.2% F.S

4.Response time:1 ~ 4 sec

5.Pressure lalawanan: 3 Mpa

6.Working environment:5 ~ 45℃

7. Modél input: 0- + 5v