FYTY Series Intelligent Measuring Imager

Panjelasan Produk

Minuhan standar: IEC60811, TB2809-2017, GB / T2951

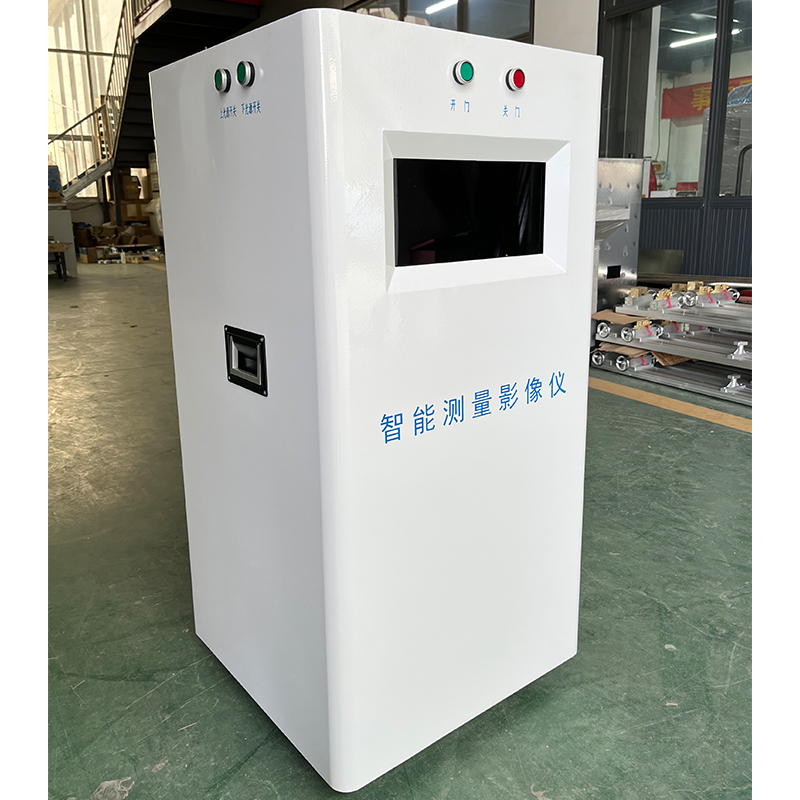

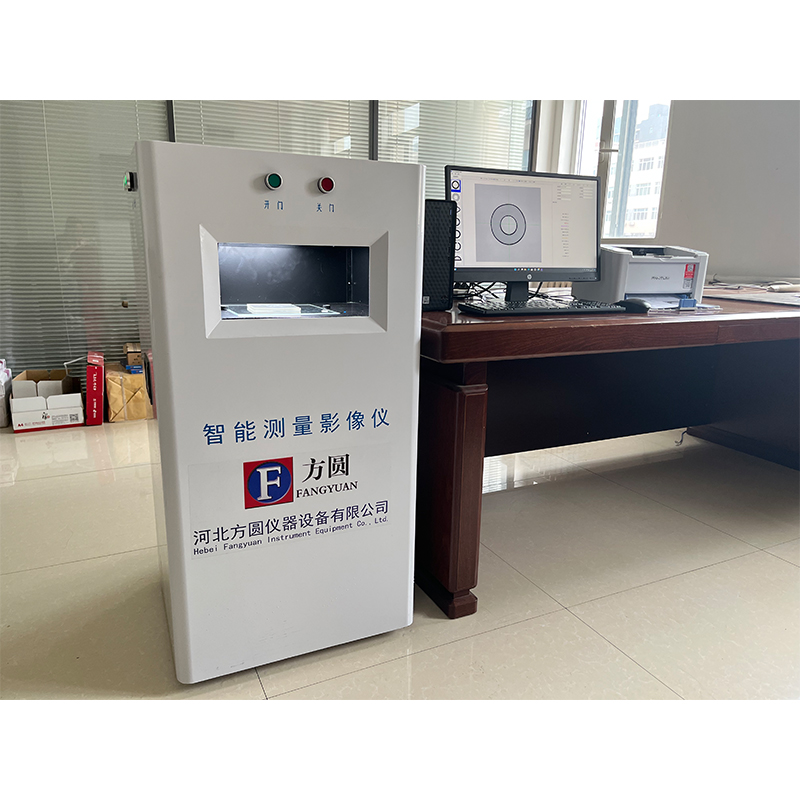

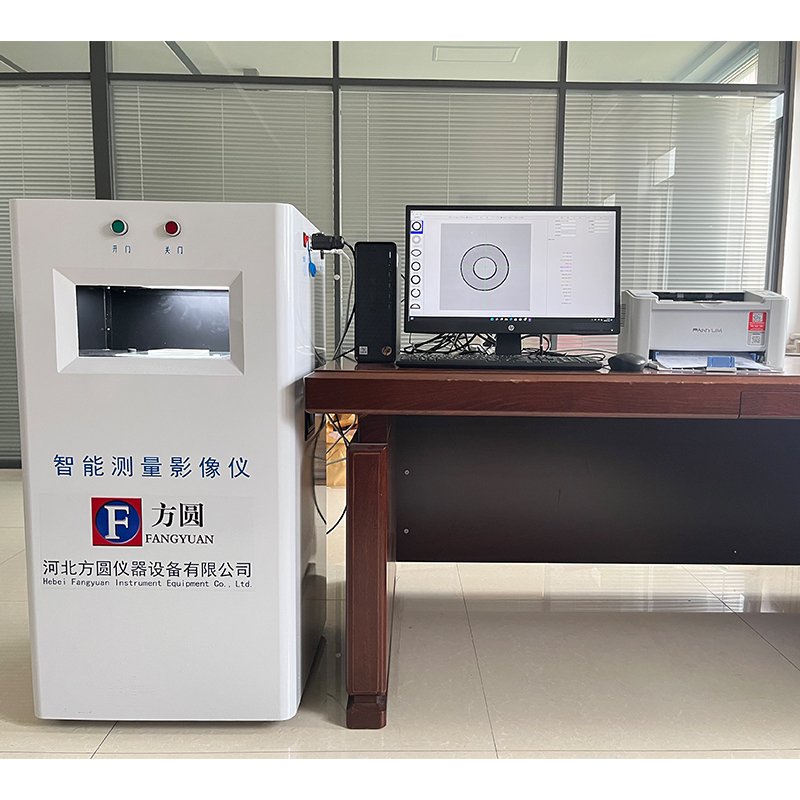

The intelligent measuring imager is an independently developed measuring system that uses visual inspection methods to measure the structure data of wires and cables. The product is designed and manufactured in accordance with the measurement requirements of the thickness and dimensions of the IEC 60811-1-1(2001)/GB/T2951.11-2008/TB2809-2017 (the implementation standard for locomotive contact wires)standards.

Ngaliwatan kombinasi visi mesin jeung téhnologi processing gambar komputer, produk ieu bisa gancang tur akurat ngadeteksi ketebalan, diaméter luar, eccentricity, concentricity, ellipticity sarta ukuran séjén tina insulasi jeung malapah tina rupa-rupa kawat jeung kabel dieusian dina standar, jeung ogé ngukur nilai aréa cross-sectional unggal lapisan jeung konduktor. Akurasi pangukuran alat jauh langkung saé tibatan akurasi anu diperyogikeun ku standar.

Fungsi jeung Fitur

Using computer vision technology, inspection is rapid and timely, far exceeding the measurement speed of manual projectors and reading microscopes. Automatic inspection of the structural parameters of the cable according to the inspection shape selected by the user enables more accurate inspection accuracy than manual measurement and the measurement specifications required by IEC 60811-1-1 (2001). Use LED parallel light sources to improve lighting uniformity and life to ensure continuous and stable light. Fast measurement data can quickly guide product production, ensure product quality, and can reduce the cost of cable production materials, reduce the error rate of human measurement and improve measuring efficiency.

Lacak kabel IEC panganyarna sareng standar kabel sareng metode tés dina waktosna. Pamutahiran program gratis disayogikeun ka pangguna, sareng struktur awak anu dirarancang sacara profésional mastikeun pangukuran anu wajar sareng dipercaya. Ngagunakeun kaméra digital industri kinerja tinggi kalawan 10 megapiksel (1-80mm) jeung 20 megapiksel (80-140mm) sensor CMOS opat grup béda tina kaméra bisa ngadeteksi rupa kawat sarta insulasi kabel sarta data ukuran palapah ti 1mm diaméterna ka 140mm diaméterna.

Konfigurasi

CCD sareng lénsa precision tinggi dianggo salaku alat akuisisi gambar pikeun ngalakukeun pencitraan sareng sampling pikeun ngahontal tés sampel anu akurat sareng stabil sareng ningkatkeun efisiensi tés.

Pangukuran non-kontak, sacara mandiri sareng obyektif ngukur obyék anu diuji, sacara efektif ngahindarkeun kateupastian pangukuran manual.

|

Barang |

Sistem operasi pangukuran calakan imager |

|||

|

Parameter tés |

Ketebalan, diameter luar sareng data elongasi tina insulasi sareng bahan sarung kabel sareng kabel optik |

|||

|

Jenis sampel |

Bahan insulasi sareng sarung pikeun kabel sareng kabel optik (elastomer, polivinil klorida, poliétilén, polipropilén, jsb.) |

|||

|

Rentang ukur |

1-10 mm |

10-30mm |

30-80mm |

80-140 mm |

|

Kaméra |

No.1 |

No.2 |

No.3 |

No.4 |

|

Jenis sénsor |

CMOS scan kutang |

CMOS scan kutang |

CMOS scan kutang |

CMOS scan kutang |

|

piksel lénsa |

10 juta |

10 juta |

10 juta |

20 juta |

|

Resolusi gambar |

2592*2600 |

2592*2600 |

2704*2700 |

3488*3500 |

|

Resolusi tampilan |

0,001 mm |

|||

|

pangulangan pangukuran (mm) |

≤0.002 |

≤0.005 |

≤0.01 |

≤0.03 |

|

Measurement accuracy (μm) |

4+L/100 |

8+L/100 |

20+L/100 |

40+L/100 |

|

Pindah lénsa |

Ganti lénsa bebas |

|||

|

waktos tés |

≤10sec |

|||

|

Prosedur tés |

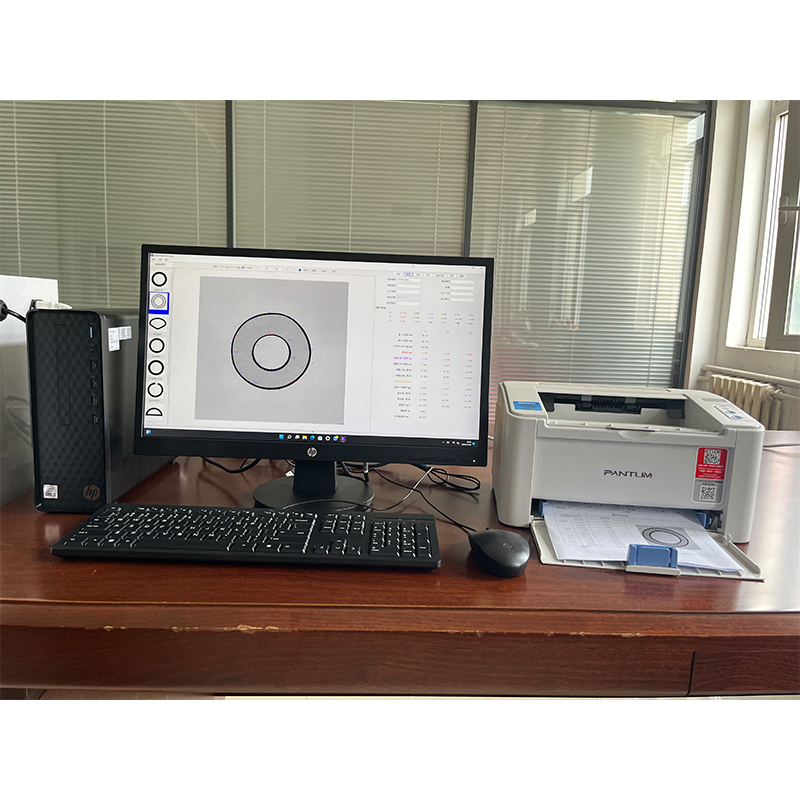

Hiji klik ukur, klik tombol pangukuran jeung mouse, software bakal diuji sacara otomatis, sadaya parameter bakal diuji dina hiji waktu, laporan test bakal dikaluarkeun otomatis, sarta data bakal disimpen dina database otomatis.

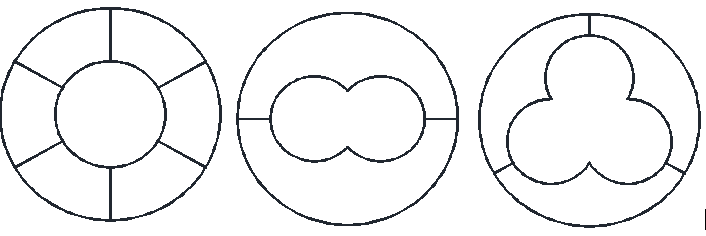

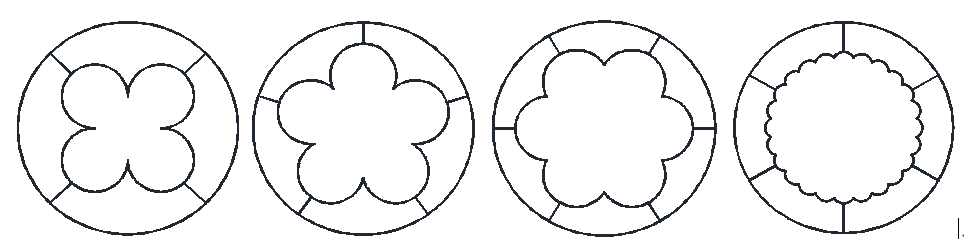

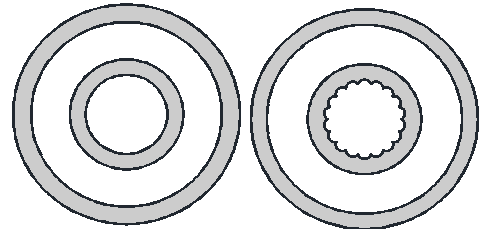

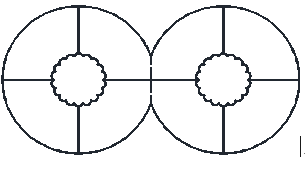

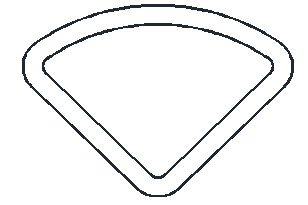

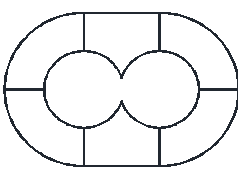

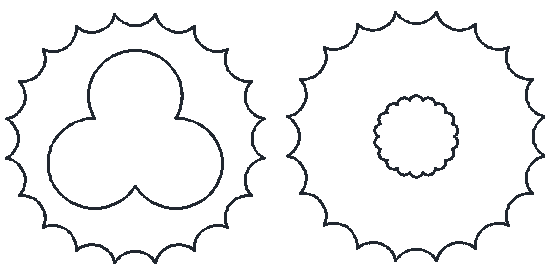

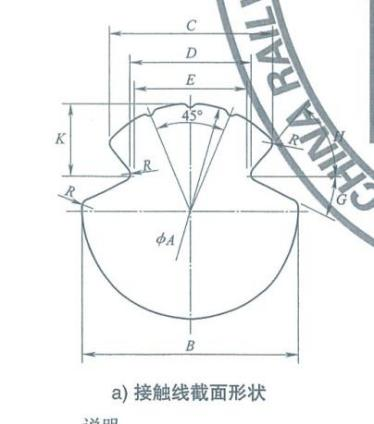

Nguji software: 1. insulasi kabel Testable sarta bentuk malapah kaasup IEC60811. Gambar 1 nepi ka Gambar 11. ①Insulasi sareng pangukuran ketebalan sarung (buleud permukaan jero) ②Ukur ketebalan insulasi (konduktor ngawangun sektor) ③Ukur ketebalan insulasi (konduktor terdampar) ④Ukur ketebalan insulasi (beungeut luar henteu teratur) ⑤Ukur ketebalan insulasi (datar inti ganda non sheathed kawat fléksibel) ⑥Ukur ketebalan sarung (permukaan jero sirkular henteu teratur) ⑦Pengukuran ketebalan sarung (beungeut jero non-circular) ⑧Ukur ketebalan sarung (permukaan luar henteu teratur) ⑨Pengukuran ketebalan sarung (tali inti ganda datar sareng sarung) ⑩Ukur ketebalan sarung (kabel datar multi-inti) TB2809-2017 (standar eksekutif pikeun kawat kontak lokomotif) ukuran bagian jeung pangukuran sudut.

2.Support test tina tilu-lapisan coextrusion kabel bentukna kabel tegangan sedeng jeung luhur.

3.Item insulasi sareng sarung tés ketebalan maksimum, ketebalan minimum jeung ketebalan rata. Diaméter maksimum, diaméter minimum, diaméter rata, aréa cross-sectional. Éccentricity, concentricity, ovality (circular).

4.Conductor rujukan aréa cross-sectional

5.Metoda pangukuran bebas dirancang dumasar kana sarat 3C: minuhan sarat tina 1.9.2 di GB / t5023.2-2008: "nyokot tilu bagian tina sampel pikeun tiap inti kawat insulated, ngukur nilai rata-rata 18 nilai (dinyakeun dina mm), itung kana dua tempat perpuluhan, sareng buleudan dumasar kana katangtuan di handap ieu (tingali istilah standar pikeun aturan rounding off), teras nyandak nilai ieu salaku nilai rata-rata ketebalan insulasi. Laporan 3C unik tiasa dibangkitkeun, kalayan fungsi determinasi kualifikasi.

6.Manual measurement function: even if you meet the section shape of wire and cable insulation thickness not listed in the standard, the manual measurement function is added in the software. Just click the position to be measured in the section view, that is, the point-to-point length will be displayed automatically. After the measurement, the minimum thickness and average thickness of these positions can be displayed automatically。 |

|||

|

Fungsi kalibrasi |

A dewan calibration ring baku disadiakeun, nu bisa dipaké pikeun calibration instrumen |

|||

|

Sumber cahaya umur panjang |

High density LED sumber lampu paralel, lampu monochromatic, ngurangan scattering tur nyorot kontur objék diukur ka extent greatest. The unik 90 derajat sudut bantu design sumber lampu cross bisa ngukur sampel opak. |

|||

|

Sistim jalur lampu |

Sasis disegel pinuh, ngadopsi sistem jalur optik debu-bukti nangtung pikeun ngirangan réfraksi optik. |

|||

|

Pangukur chamber lampu |

Ruang cahaya hideung sadayana ngirangan pantulan anu sumebar, ngaleungitkeun gangguan cahaya anu nyimpang, sareng ngahindarkeun kasalahan data palsu. |

|||

Parameter Sumber Cahaya

|

Barang |

Tipe |

Warna |

Paneangan |

|

Lampu tukang paralel |

LED |

Bodas |

9000-11000LUX |

|

2 sumber cahaya bantu silang |

LED |

Bodas |

9000-11000LUX |

Komputer

Prosesor Intel G6400, quad-core, 4.0GHz, mémori 4G, hard drive 1TG, tampilan 21,5 inci, sistem operasi window10

Printer

Printer laser, kertas A4, percetakan hideung bodas

Sampel

Potongan buleud (7 jinis)

Regular ring Double-core round Three-core round

Four-core round Five-core round Six-core round Irregular ring

Cincin tilu lapis (2 jinis)

gambaran: ring lemes internal tur ring burr internal

Smooth inner ring Internal burr ring

Teleskop (1 tipe)

Sektor (1 jinis)

Datar inti ganda (1 jinis)

Bulat permukaan henteu teratur (2 jinis)

Single-layer three-core irregular circles Single-layer irregular circles inside and outside

TB2809-2017 (Standar Eksekutif pikeun Kawat Kontak Lokomotif) Dimensi Sectional sareng Pangukuran Sudut

Ukur lapisan insulasi tina opak ganda-lapisan atawa triple-lapisan karét sheathed kabel tegangan tinggi

Paké Kaayaan Lingkungan

|

No. |

Barang |

Unit |

Unit proyék diperlukeun nilai |

||

|

1 |

Suhu lingkungan |

Suhu poean maksimum |

℃ |

+40 |

|

|

Suhu harian minimum |

-10 |

||||

|

Beda suhu poean maksimum |

℃ |

30 |

|||

|

2 |

Luhurna |

M |

≤2000 |

||

|

3 |

Kalembaban relatif |

Kalembaban relatif poean maksimum |

|

95 |

|

|

Kalembaban relatif rata-rata bulanan maksimum |

90 |

||||

Konfigurasi mesin

|

Barang |

Modél |

Qty |

Unit |

|

|

Pangukuran calakan |

FYTY-60 |

1 |

Nyetél |

|

|

1 |

Mesin |

|

1 |

Nyetél |

|

2 |

Komputer |

|

1 |

Nyetél |

|

3 |

printer laser |

|

1 |

Nyetél |

|

4 |

Papan kalibrasi |

|

1 |

Nyetél |

|

5 |

Kaca dipencet |

150*150 |

1 |

Sapotong |

|

6 |

kabel data USB |

|

1 |

Sapotong |

|

7 |

Parangkat lunak |

|

1 |

Nyetél |

|

8 |

Parentah Operasi |

|

1 |

Nyetél |