LED Ultraviolet Irradiation Polyolefin Crosslinking Equipment

Panjelasan Produk

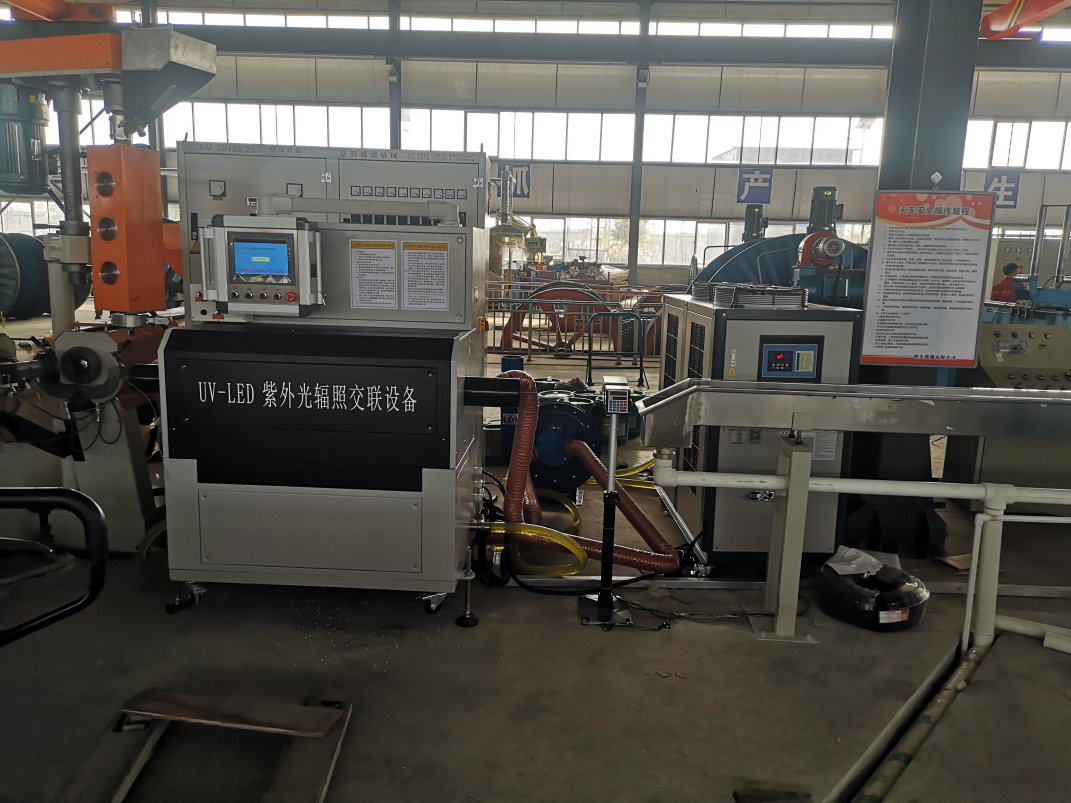

The new LED ultraviolet irradiation polyolefin cross-linking equipment adopts the new technology. The power consumption of the LED lamp is 70% lower than that of the old irradiation, and the cross-linking speed is more than twice of the original. The new product solves the shortcomings of the thick insulation, impervious to radiation and slow speed. Less land occupation, more reasonable design, eliminating the steam cross-linking process, greatly improving production efficiency. Significant cost and time savings based on customer response.

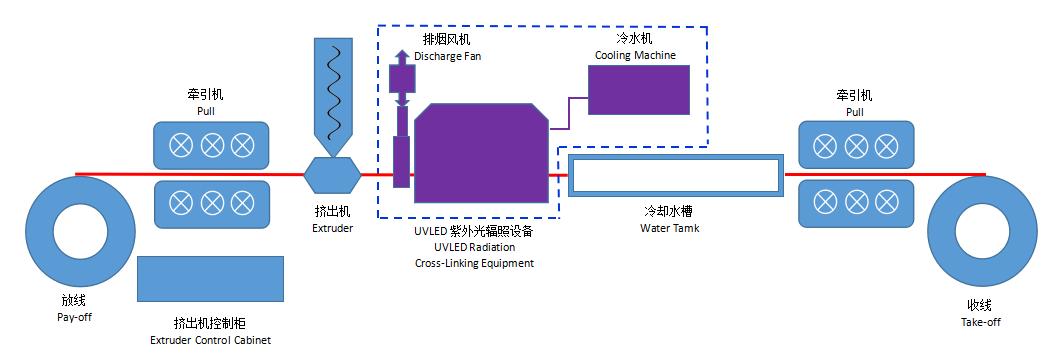

The process of UV irradiation polyolefin crosslinking equipment uses ultraviolet light as a radiation source, and the mixed photo-crosslinked polyolefin compound is extrusion-molded on the conductive core, and then immediately enters into a special irradiation equipment. The molten state is crosslinked by light. The light-crosslinked polyolefin insulated wire and cable products can be obtained by the light-radiated cross-linked insulated core after cooling treatment at different temperatures and other subsequent processing.

The UV irradiation polyolefin crosslinking equipment only needs to be slightly modified in the original ordinary extrusion production line, and the upper traction, radiation box, electric control cabinet, etc., which occupy a small area, can be installed to meet the operational requirements and produce UV irradiated crosslinked polyethylene wire and cable products.

Ciri

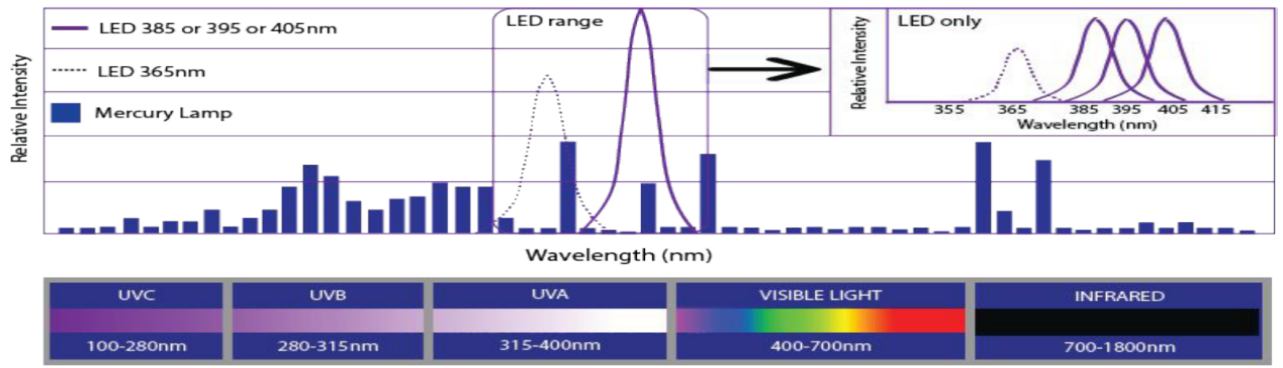

Alat LED Ultraviolet mangrupikeun sumber radiasi sinar ultraviolét anu paling canggih di dunya, kalayan efisiensi énergi anu luhur (sakitar 30%), selektivitas panjang gelombang anu efektif pisan tinggi (bandwidth panjang gelombang satengah kakuatan 5nm), umur jasa anu luhur pisan (30,000 jam), infra red Panas rendah. generasi, euweuh generasi ozon, leuwih cocog pikeun cross-linking curing of cross-numbu polyolefin jeung bahan séjén.

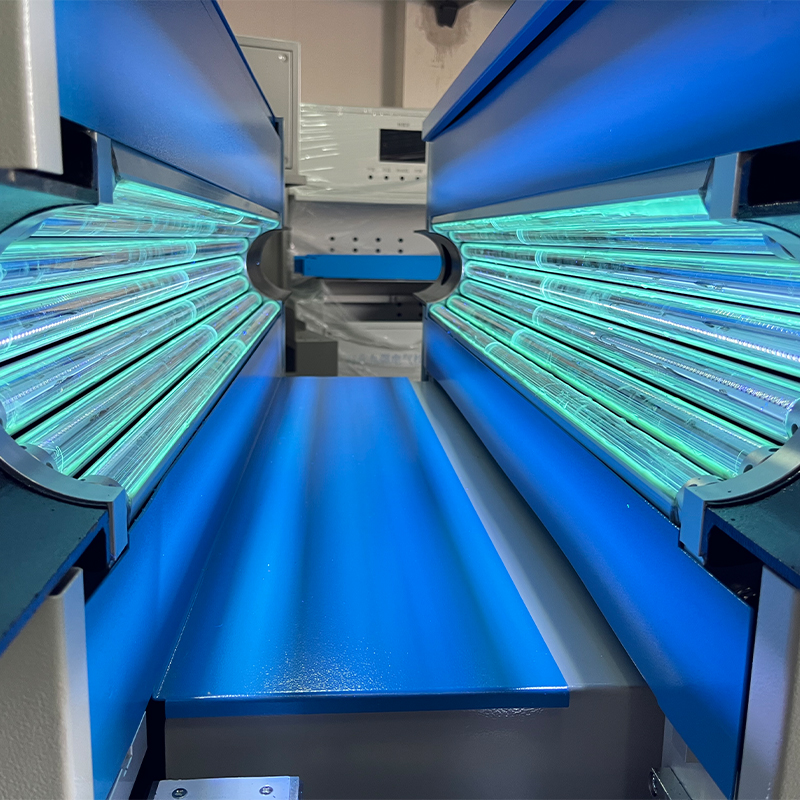

Sumber UV LED ngagunakeun struktur lénsa dipaténkeun pikeun nyaangan beungeut kabel leuwih merata sarta seragam. Desain substrat dilumangsungkeun ku kombinasi cairan simulasi software Fluent jeung test suhu simpang LED, sarta circuit board LED dirancang ku kombinasi keramik aluminium nitride jeung basa tambaga jeung kinerja dissipation panas hadé, sarta ngabogaan dissipation panas leuwih efisien. sistem.

Sumber UV LED ngagunakeun sumber daya jaringan disebarkeun pikeun ngajalankeun LED UV. Catu daya nyetir dibungkus dina prosés potting vakum pikeun mastikeun réliabilitas catu daya. Dina waktu nu sarua, bentuk catu daya nyetir adopts hiji perenah sempit tur panjang, sarta panjang-tipe sumber lampu LED adopts hiji deui-ka-balik mode instalasi pikeun sirkuit LED pikeun ngaleutikan panjang kawat. Nyatakeun fungsi sumber cahaya hurung, pareum, sareng peredupan.

The UV LED irradiation polyolefin cross-linking parabot adopts struktur torowongan rongga sirkular, sarta dilengkepan sumber lampu LED ultraviolét pikeun ngabentuk torowongan pikeun irradiating wewengkon sentral, sarta kakuatan alat bisa steplessly diatur dina rentang 10 nepi ka 100%.

Dibandingkeun sareng alat-alat crosslinking iradiasi lampu raksa tradisional (tradisional trafo-disetir UVI / UVI sareng éléktronik UVE-I anu didorong ku kakuatan), cross-linking akselerator éléktron, sareng silane cross-linking, éta gaduh kaunggulan ieu:

1 Konsumsi Énergi Lemah

UV LED irradiation polyolefin cross-linking parabot dipasang kakuatan anu sarua jeung 1/4 tina parabot irradiation ultraviolét aslina, 1/30 tina akselerator éléktron, cai atawa uap cai perlu pemanasan jangka panjang, sarta konsumsi énergi cai pemanasan pisan. luhur.

2 Waktos pondok

The cross-linking adopts métode cross-linking Tonjolan online pikeun ngurangan prosés processing cross-linking saterusna, dibandingkeun jeung waktu diperlukeun pikeun pindang atawa uap-ditulungan silane cross-linking jeung commissioned processing irradiation sinar éléktron, nyimpen kawat jeung waktu manufaktur kabel. , utamana darurat The parantosan misi, kaunggulan signifikan.

3 Biaya rendah

Dibandingkeun sareng cross-linking cai haneut sareng pamrosésan sinar sinar éléktron anu ditugaskeun, harga kabel irradiasi ultraviolét rendah, sareng seueur prosés pajeulit diréduksi dina prosés produksi, sapertos biaya transportasi kabel semi-rengse sareng biaya operator anu saluyu.

4 Henteu Ozon

Selectivity panjang gelombang pisan tinggi, ngan emits panjang gelombang mangpaat, euweuh radiasi infra red, nilai calorific low; jumlah pisan low radiasi katempo, euweuh polusi cahaya; euweuh radiasi ultraviolét panjang gelombang pondok, euweuh ngarugikeun ka awak manusa, enol émisi ozon. Teu peryogi cooling aliran hawa kipas kakuatan tinggi, teu peryogi saluran hawa panas-discharging sareng ozon-discharging khususna rumit, ngan ukur kedah nyambungkeun pipa knalpot berdiaméter leutik sareng kipas 2kW pikeun ngaluarkeun haseup molekul rendah anu dihasilkeun nalika ékstrusi insulasi. . Nyegah épék radiasi cahaya.

5 Ukuran Leutik, Gampang Dipasang

Kantun tambahkeun jarak kira-kira 2m antara kapang extruder garis produksi asli sareng tangki cai haneut, sareng nempatkeun mesin iradiasi dina rohangan 2.5 ~ 3 méter lebar, atanapi langkung sempit. Chiller tiasa ditempatkeun di tempat.

6 Gampang Dioperasikeun

Bukaan jempé tur nutup struktur torowongan, gampang pikeun ngabersihan jeung ngagem ngawujud, gampang beroperasi, euweuh prosés pajeulit, bisa réngsé ku operator extruder.

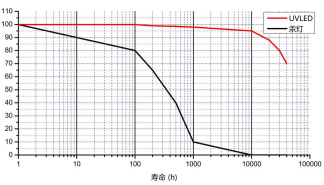

7 Umur Panjang Jeung Biaya Pangropéa Low

Hirupna alat-alat LED sakitar 30,000 jam, sareng umur alat listrik sareng éléktronik sanés langkung handap tina umur produk listrik sareng éléktronik umum, tanpa pangropéa sering. Pangropéa teratur pikeun ngajaga lénsa optik bersih, anu tiasa dianggo nyaéta wipes industri sareng pembersih soot, anu tiasa dilakukeun ku operator. Consumables parabot irradiation lampu tradisional nyaéta lampu UV jeung reflectors, nu kudu diganti dina waktu anu singget. Unit irradiation sinar éléktronik ogé diperlukeun pikeun ngajaga tim pangropéa.

8 Héjo

Standar Kualitas Udara Ambient (GB3095-2012) dina Standar Kabersihan Industri netepkeun yén standar kaamanan ozon nyaéta 0.15ppm. UVLED UV crosslinking parabot moal ngahasilkeun ozon, bari parabot lampu raksa tradisional bakal ngahasilkeun jumlah badag ozon. Ozon nyaéta gas ngabahayakeun.

1) rupa-rupa aplikasi

Ultraviolet irradiation polyolefin cross-linking equipment can achieve a uniform cross-linking thickness of more than 2mm, which can be used for the production of various cross-linked polyethylene cables, flame-retardant cross-linked cables and other cables. The production speed is high and the application range is wide, which can match the production speed of the wire and cable production line.

2) béaya rendah

The price of UV-irradiation polyolefin cross-linking equipment is only 1/10-1/5 of the electron beam irradiation equipment. Installation only needs to add the equipment on the basis of the original extrusion line, no need for other equipment investment. Compared with the first-generation equipment, the annual electricity bill and production efficiency cost can save one piece of equipment.

3) Gampang dipasang

The UV-irradiation polyolefin cross-linking equipment adopts a modular design, and only needs to be connected by pipelines between the parts, and the installation is convenient. The modular design allows for greater flexibility in the placement of the equipment, fully meeting the installation needs of various production sites.

4) reliabilitas tinggi

Ultraviolet irradiation polyolefin cross-linking equipment adopts advanced and stable control method, high-reliability component parts, all non-standard parts are designed with high life, strict material selection and precision processing level, assembly link has high quality requirements. Finally, after very rigorous testing, each device can operate safely and reliably, maximizing the stability and service life of the equipment.

Perbandingan kaunggulan tina irradiation LED anyar cross-linking jeung silane cross-linking:

|

sinar ultraviolét LED parabot |

Parabot silang silang |

Hemat ongkos |

|

|

Biaya bahan |

600 kg runtah per 90 extruders per taun |

12 ton runtah per 90 extruders per taun |

Annual cost savings of 17000 USD per machine per 90 machines |

|

kakuatan Extruder |

Viskositas bahan anu leutik, konsumsi kakuatan anu leutik, sarta Tonjolan of 90 extruder ngan ngeunaan 30KW di speed pinuh. |

Viskositas tinggi bahan, konsumsi kakuatan tinggi, 90 KW speed pinuh Tonjolan diperlukeun |

Save 20KW per hour, save electricity costs of 10000 USD per extruder per year |

|

Tagihan listrik jieunan |

Teu perlu ngabersihan extruder nu |

Ngabersihan extruder satengah jam unggal dinten |

Simpen 3400 USD per taun |

|

Biaya cross-linking |

Nyandak 35 méter pasagi sabagé conto, biaya listrik nyaéta 80KW pikeun 30.000 méter. |

Nyokot 35 méter pasagi sabagé conto, butuh 4 jam pikeun 30.000 méter uap cross-linking, sarta merlukeun 200KW listrik. |

Save about 7000 USD in electricity every year |

|

Produktivitas |

Sakaligus cross-linking kalawan extruder nu, insulasi Tonjolan ieu langsung cabled tanpa processing sekundér. |

Kulub atanapi kukus sahenteuna sahenteuna 4 jam (merlukeun situs khusus, generator uap) |

Save 8400 USD per year |

|

kualitas produk |

Panas shrinkage kirang ti 4%, euweuh gél saméméhna, permukaan lemes |

Nyusut panas parah, insulasi bagian melintang leutik sering gaduh permukaan anu teu mulus sareng gél. |

|

|

Investasi parabot |

Sedeng |

Low (kamar uap atawa kolam renang haneut) |

|

|

Konsumsi kakuatan |

Lemah (ngan peryogi 10 KW) |

Tinggi (merlukeun pemanasan panjang) |

|

|

Biaya produksi |

Lemah |

Luhur |

|

|

Daur produksi |

Singkat (online cross-linking) |

Panjang (merlukeun pamrosesan sekundér) |

|

|

Compared with silane cross-linking, UV irradiation machine saves nearly 50000 USD per year. |

|||

Ngabandingkeun kaunggulan tina irradiation LED anyar jeung sambungan online kalawan tekanan tinggi lampu raksa heubeul:

|

mesin irradiation ultraviolét LED |

Mesin iradiasi lampu raksa tekanan tinggi heubeul |

|

|

Konsumsi kakuatan |

Rata-rata kirang ti 15 kW per jam |

80KW per jam |

|

Biaya pangropéa |

Lemah |

Luhur |

|

Laju produksi |

Luhur |

Lemah |

|

Hirup lampu |

30000 jam |

400 jam |

|

Consumables |

No |

Lampu, pemantul, kapasitor |

|

Produktivitas |

Extruder teu diwatesan ku speed tinggi na bisa dihasilkeun ku ngahurungkeun lampu. |

Laju produksi slow, efisiensi low, runtah tanaga gawé, perlu preheat satengah jam sateuacanna |

|

Operasi sareng rohangan lantai |

Operasi basajan, tapak suku leutik, euweuh antosan |

Operasi kompléks sareng rohangan lantai ageung |

|

LED mesin irradiation anyar ngaheéat 34.000 USD listrik expenses.17.000 USD waragad kuli sarta 8.400 USD consumables per taun ti-tekanan tinggi lampu raksa mesin irradiation heubeul. |

||

LED sareng lampu raksa kontras spéktral

Bandingan hirup lampu LED sareng raksa

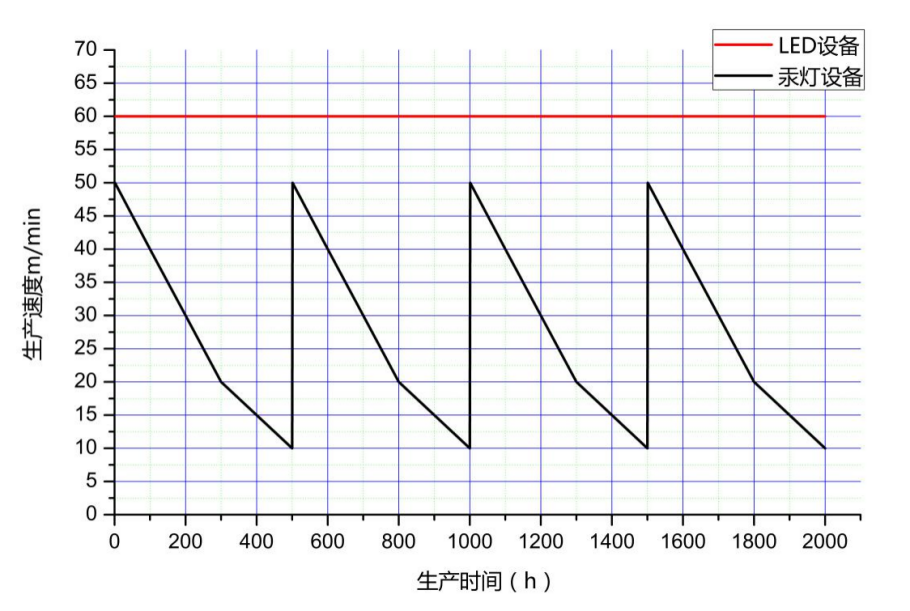

Perbandingan kurva laju produksi antara alat iradiasi lampu raksa sareng alat iradiasi LED

Parameter Kinerja Parameter Perlengkapan Crosslinking Iradiasi UV-LED:

- 1. Daya: tilu-fase sistem lima kawat (380V + N + taneuh)

- 2. Total kakuatan mesin dipasang: 20kW

- 3. Diaméter pangalusna wewengkon irradiation: 30mm

4. Panjang irradiation éféktif: 1m

- 5. Manik-manik lampu nganggo sumber cahaya anu diimpor paling luhur di dunya, lénsa nganggo quartz impor, supados gaduh leungitna énergi anu langkung handap, set lampu nganggo téknologi penyejukan cair, supados sumber lampu LED gaduh umur jasa anu langkung panjang.

- 6. The catu daya adopts Taiwan Mingwei catu daya waterproof, nu ditangtayungan ku téhnologi vakum potting, kalawan overload, circuit pondok, leuwih ayeuna, leuwih tegangan jeung leuwih panyalindungan suhu.

7. kaluaran kakuatan optik bisa wenang disaluyukeun tina 10% -100%, nurutkeun customer perlu ngaluyukeun kakuatan nanaon.

- 7. Kahirupan sumber lampu: 30.000 jam (disadiakeun ku produsén) Inténsitas cahaya kaluaran attenuated ka 70% (efisiensi turun ka 70%). Waktu pamakean nyaéta 30,000 jam, sareng waktos itungan nyaéta 6 ~ 10 taun.

9. Ukuran kotak iradiasi: 1660mm * 960mm * 1730mm (panjang x lebar x jangkungna)

Fitur struktur alat:

- 1. lawang jempé tur nutup struktur torowongan, gampang pikeun beroperasi tur bersih;

- 2. Ngagunakeun panganteur lalaki-mesin touch calakan, data mantau, sarta setélan kakuatan tombol operasi anu sadayana réngsé dina panganteur layar rampa;

- 3. Fungsi kontrol layar rampa jeung tombol mimiti hirup babarengan misah;

- 4. Metodeu cooling ieu leuwih tiis ku chiller a, sarta medium sirkulasi dijieunna tina bahan keur anti ngagibleg husus pikeun mobil;

- 5. mékanisme panyabutan haseup éksternal, discharged ngaliwatan saluran hawa outdoor

perenah parabot

Laju produksi bahan irradiated poliétilén cross-linked

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Kepala mesin |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²) |

Ketebalan nominal insulasi (mm)

|

Laju produksi alami (m / mnt)

|

Panambahan panas (%)

|

deformasi permanén |

|||

|

1.5 |

0.7 |

50-150 |

50-110 |

0-10 |

|||

|

2.5 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

4 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

6 |

0.7 |

50—150 |

50~110 |

0~10 |

|||

|

10 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

16 |

0.8 |

50—140 |

50~110 |

0~10 |

|||

|

25 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

35 |

0.9 |

50—100 |

50~110 |

0~10 |

|||

|

50 |

1.0 |

40—100 |

50~110 |

0~10 |

|||

|

70 |

1.1 |

40—90 |

50~110 |

0~10 |

|||

|

95 |

1.1 |

35—90 |

50~110 |

0~10 |

|||

|

120 |

1.2 |

35—80 |

50~110 |

0~10 |

|||

|

150 |

1.4 |

30—70 |

50~110 |

0~10 |

|||

|

185 |

1.6 |

30—60 |

50~110 |

0~10 |

|||

|

240 |

1.7 |

25—45 |

50~110 |

0~10 |

|||

|

300 |

1.7 |

25—35 |

50~110 |

0~10 |

|||

Laju produksi bahan iradiasi bébas halogén haseup rendah

|

Zona 1

|

Zona 2

|

Zona 3

|

Zona 4

|

Zona 5

|

Kepala mesin |

||

|

135 ℃ |

150 ℃ |

160 ℃ |

175 ℃ |

180 ℃ |

180 ℃ |

||

|

Conductor cross section (mm²)

|

Ketebalan nominal insulasi (mm)

|

Laju produksi alami (m / mnt)

|

Panambahan panas (%)

|

deformasi permanén |

|||

|

1.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

2.5 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

4 |

0.7 |

50~150 |

35~65 |

0~10 |

|||

|

6 |

0.9 |

30~150 |

25~65 |

0~10 |

|||

|

10 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

|

16 |

1.0 |

30~100 |

25~65 |

0~10 |

|||

Catetan: Kusabab alat-alat Tonjolan jeung prosés produksi jeung bahan kabel tina usaha béda béda, laju Tonjolan bakal béda. The 90 extruder henteu kawates.

Instalasi dina situs tina sinar ultraviolét LED mesin cross-linking