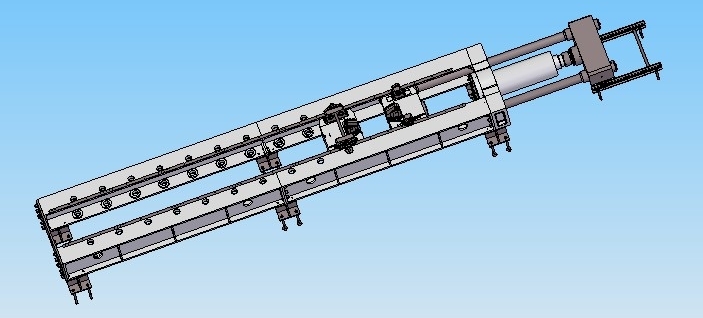

TXWL-600 Electro-Hydraulic Servo Mesin Uji Tensile Horizontal

Panjelasan Produk

TXWL-600 electro-hydraulic servo horizontal tensile testing machine adopts horizontal frame structure, single rod double-acting piston cylinder exerts test force, and the computer control system realizes the automatic control of the test process by controlling servo valve and other components, the test data akurat dikumpulkeun ku sensor beban sarta dikirimkeun ka komputer, sistem otomatis nganalisa, prosés jeung nyimpen hasil tés, sarta printer bisa langsung nyitak laporan test diperlukeun. Mesin ieu utamana dipaké pikeun uji tensile tina tali kawat baja, mangrupakeun produksi modern panalungtikan ilmiah sarta pangajaran sarta industri lianna pikeun minuhan sarat tina parabot test idéal.

Mesin Pedaran

1.Sistim host

Bagian mesin utama utamana diwangun ku pigura mesin utama, korsi silinder minyak, silinder minyak, balok pindah, hareup jeung korsi cuk pungkur jeung sensor beban. Éta tiasa ngalaksanakeun tés tensile kalayan beban maksimal 600kN dina sampel.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Wewengkon tés dilengkepan ku panutup pelindung, anu sacara efektif tiasa ngajagi kasalametan tanaga tés.

2. Sistem sumber minyak

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3. Bagian Listrik

Kontrol listrik diatur di daérah operasi tés, sareng aya panel operasi anu dirarancang khusus pikeun ngajantenkeun sagala jinis operasi sakedapan. Komponén listrik mangrupikeun merek terkenal internasional, kalayan kinerja stabil sareng kualitas anu tiasa dipercaya.

Sistem parangkat lunak:

(1) Dumasar kana platform operasi Windows XP jeung fungsi programmable, kontrol gaya test sarua-rate, kontrol kapindahan sarua-rate, nyekel gaya test, kapindahan nyekel jeung modus test lianna bisa digabungkeun dina will pikeun minuhan sarat tina rupa métode test. ka extent maksimum, sarta pikeun ngawujudkeun rupa tampilan data, gambar kurva, ngolah data, neundeun jeung fungsi percetakan diperlukeun pikeun ujian.

(2) Kirim sinyal kontrol ka klep servo ngaliwatan komputer pikeun ngadalikeun lawang jeung arah klep servo, kukituna ngadalikeun aliran kana silinder, sarta merealisasikan kadali gaya test sarua-rate, kapindahan sarua-rate, jsb .

(3) Dilengkepan dua puteran kontrol loop katutup tina gaya uji sareng kapindahan.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Antarbeungeut utama boga sagala fungsi operasi poean test, kayaning Éntri informasi sampel, Pilihan sampel, gambar kurva, tampilan data, processing data, analisis data, operasi test, jsb Operasi test téh basajan tur gancang.

(6) Data tiasa kaluaran ka printer pikeun nyitak laporan tés.

(7) Manajemén hirarki sistem, parameter sistem sadayana kabuka pikeun pangguna ahli, mastikeun kalenturan sareng reliabilitas sistem.

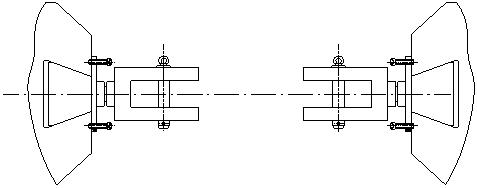

4.Asesoris Test

Dilengkepan asesoris tés tali kawat (tempo di handap) sareng asesoris sanésna didamel dumasar kana standar anu disayogikeun ku pangguna atanapi sarat tensile tina sampel.

5.Safety Protection Alat

(1) Overload panyalindungan nalika gaya test ngaleuwihan 2% nepi ka 5% tina gaya test maksimum atawa nilai set.

(2) Perlindungan stroke nalika piston pindah ka posisi wates.

(3) Kalayan suhu minyak, tingkat cair sareng panyalindungan lalawanan minyak sareng alat indikasi.

(4) Ruang uji ngagaduhan panutup pelindung pikeun nyegah sampelna pecah sareng murag.

(5) Nalika kaayaan darurat lumangsung, pencét tombol eureun darurat dina kabinet kontrol langsung

Parameter Téknis

1. Gaya uji maksimum: 600kN

2.Uji rentang ukur gaya: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile test spasi (kaasup piston stroke): 20mm ~ 12000mm

5. Piston stroke: 1000mm

6.Laju kerja maksimum piston: 100 mm / mnt

7.Deformation akurasi extensometer: 0.01mm

8. Dimensi mesin utama (mm): 16000 (L) x 1300 (W) x 1000 (H) (kaasup panutup pelindung)