Wire and Cable Smoke Density Test Machine

Product Description

Comply with GB/T17651.1~2, IEC61034-1~2. The determination of smoke density is an important aspect of assessing the burning characteristics of cables or optical cables, which is related to the evacuation of personnel and the ability to approach the determination of fire fighting.This instrument is mainly used to determine the concentration of smoke released when the cable and optical cable are burned under specific conditions, and to verify the density of smoke produced. Under flame burning or flameless burning conditions, light transmittance is used as a way to compare different cables or optical cables under specific conditions.

Features

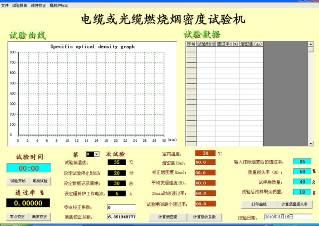

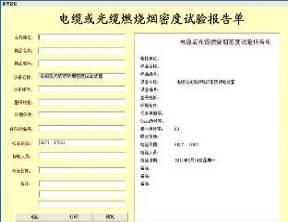

This instrument involves professional knowledge in three aspects of machinery, optics, and electronics. It is an electromechanical integration product with reasonable structure, stable performance, and easy operation. WINDOWS 10 operating interface, LabVIEW style, and perfect security mechanism. During the test, the measurement results are displayed in real time and the perfect curve is dynamically drawn (displaying the transmittance and time curve). The data can be permanently saved, read and printed out, and the report can be printed directly.

Principle

The smoke density optical measurement system of the cable or optical cable burning under specific conditions is composed of a light source, a silicon photocell, a light source receiver and a computer system.The light generated by the light source passes through the smoke density laboratory of 3 × 3 × 3(m) to form a uniform beam with a diameter of 1.5m±0.1m on the wall opposite the light source. The photocell installed at the center of the beam detects the intensity of the beam from the light source. When a large amount of smoke is generated in the combustion chamber due to burning cables or optical cables, the smoke absorbs a part of the photoelectricity, and the intensity of the beam reaching the silicon photovoltaic cell is weakened. By processing the data through the computer system, it can be calculated that it is 100% relative to the initial Linear response light transmittance.

Composition

The entire instrument consists of closed test chamber, photometric measuring system, alcohol tray, combustion system, igniter, test box, cable holder, temperature measuring instrument and smoke density testing software. The circuit is developed by single chip microcomputer, with high technical content and stable performance. This instrument is suitable for all cables and is widely used by the production factories of wire and cable industry as well as scientific research and testing departments. The test box is a test cube with a volume of 27m3.

Technical Parameter

1.Combustion chamber: internal dimensions: 3 × 3 × 3(m) total 27 cubic meters. It can be a brick wall structure or a steel plate structure, which can be chosen by customers.

2.Light measurement device:

A.The light source is imported quartz halogen lamp: nominal power 100W, nominal voltage: 12V, nominal light return: 2000 ~ 3000Lm.

B.Receiver: silicon photovoltaic cell, 0% light transmission means no light passes through, 100% light transmission means light passes through completely without blocking.

- 3.Standard fire sources

A.Fire source is 1.0 L alcohol.

B.Alcohol tray: stainless steel, bottom 210 x 110(mm), top 240 x 140(mm), height 80mm

4.Mixing of smoke: Use a desktop fan to make the smoke evenly distributed in the combustion chamber.

5.Blank test: Burning alcohol lamp makes the temperature of the combustion chamber reach 25±5℃.

6.Temperature measuring device: a temperature sensor is installed at a height of 1.5m from the inner surface of the door to the ground and 0.5m from the wall.

7.A set of transmittance measurement software is included, which can output curves and reports.

8.Including a computer (not including printer)

9.Power: 220V, 4kW

10.(Smoke density) 0 ~ 924 six-speed automatic shift

11.Measuring range: 0.0001 ~ 100%

12.Measurement accuracy: ±3%

13.Working voltage: 200 ~ 240V,50Hz

14.Ambient temperature: room temperature ~ 40℃

15.Relative temperature: ≤85%

16.Working environment: When the instrument is running, it should avoid direct light and no forced air flow.

17.The front door is equipped with a window and movable opaque light shield that can block the view.

18.Square box bottom installed with automatic ignition device, the top installed with the box internal pressure adjustment device.

19.Light source: 12V incandescent lamp, light wavelength 400 ~ 750nm

20.Combustion system: consists of pressure regulator valve, filter, regulator valve flowmeter, burner.

21.Burner: consisting of an igniter and an alcohol tray, placed in the centre of the sample.

Main configuration

1.Computer desktop (with display): 1 pc

2.Analysis software: 1 set

3.Calibration lens: 3 pcs

4.Spare bulb:1 pc

5.Operating Instructions

6.Certificate of conformity